Preparation method for walnut shell active carbon adsorbent for purifying low concentration phosphine

A technology of activated carbon adsorption and walnut shell, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of small adsorption capacity, consumption of oxidants, and the remaining concentration of phosphine is not mentioned, and achieve high adsorption activity. , the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

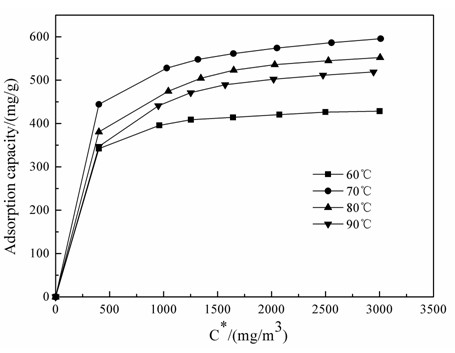

Image

Examples

Embodiment 1

[0021] The raw walnut shells were crushed to a particle size of 0.5-1 cm, washed, and dried at 100°C until constant weight; the washed and dried raw walnut shells were carbonized in a tube furnace for 1 hour under nitrogen protection, and the carbonization temperature was 600°C. The heating rate is 10°C / min; the carbonized material and the activator potassium hydroxide are mixed evenly in a certain proportion, and then placed in a tube furnace for activation under nitrogen protection for 1 hour, wherein the mass ratio of the carbonized material to the activator potassium hydroxide is 1 : 2, the activation temperature is 800°C, and the heating rate is 10°C / min; the walnut shell activation sample is washed twice with 0.1mol / L hydrochloric acid, and rinsed to neutrality with hot distilled water, and the washed sample is constant at 110°C After that, walnut shell activated carbon is obtained; the walnut shell activated carbon is modified by metal loading, and the metal active compo...

Embodiment 2

[0025]The raw walnut shells were crushed to a particle size of 0.5-1 cm, washed, and dried at 100°C until constant weight; the washed and dried raw walnut shells were carbonized in a tube furnace for 1 hour under nitrogen protection, and the carbonization temperature was 700°C. The heating rate is 20°C / min; the carbonized material and the activator potassium hydroxide are mixed evenly in a certain proportion, and then placed in a tube furnace for activation under nitrogen protection for 1 hour, wherein the mass ratio of the carbonized material to the activator potassium hydroxide is 1 : 2, the activation temperature is 900°C, and the heating rate is 15°C / min; the walnut shell activation sample is washed twice with 0.1mol / L hydrochloric acid, and rinsed to neutrality with hot distilled water, and the washed sample is constant at 110°C After that, walnut shell activated carbon is obtained; the walnut shell activated carbon is modified by metal loading, and the metal active compon...

Embodiment 3

[0029] The raw walnut shells were crushed to a particle size of 0.5-1 cm, washed, and dried at 100°C until constant weight; the washed and dried raw walnut shells were carbonized in a tube furnace for 1 hour under nitrogen protection, and the carbonization temperature was 700°C. The heating rate is 5°C / min; the carbonized material and the activator potassium hydroxide are mixed evenly in a certain proportion, and then placed in a tube furnace for activation under nitrogen protection for 1 hour, wherein the mass ratio of the carbonized material to the activator potassium hydroxide is 1 : 4, the activation temperature is 700°C, and the heating rate is 20°C / min; the walnut shell activation sample is washed twice with 0.1mol / L hydrochloric acid, and rinsed to neutrality with hot distilled water, and the washed sample is constant at 110°C After that, walnut shell activated carbon is obtained; the walnut shell activated carbon is modified by metal loading, and the metal active compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakthrough adsorption capacity | aaaaa | aaaaa |

| Breakthrough adsorption capacity | aaaaa | aaaaa |

| Breakthrough adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com