Method for performing black electroplating treatment on aluminum-based carborundum composite

An aluminum-based silicon carbide and composite material technology, applied in the field of metal material anti-corrosion technology and surface treatment, can solve the problems of difficulty in coloring, the coloring process can not meet the requirements of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

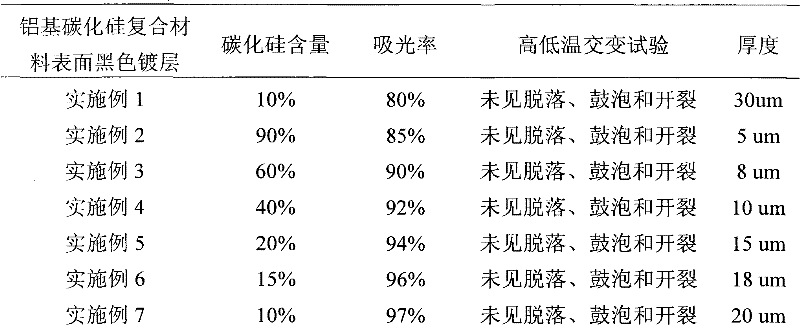

Examples

Embodiment 1

[0021] Embodiment 1: The material of the plated part is an aluminum-based composite material with a silicon carbide content of 10%.

[0022] 1) The alkaline cleaning solution is an aqueous solution of sodium hydroxide 5g / L and sodium dodecylsulfonate 10g / L, and its process parameters are temperature 85°C and time 10min.

[0023] 2) The pickling solution is 200ml / L of nitric acid, 100ml / L of sulfuric acid, 50ml / L of hydrofluoric acid, and 200g / L of chromic anhydride. The temperature is room temperature and the time is 10s.

[0024] 3) The black electroplating solution is an aqueous solution containing 200g / L of nickel sulfate, 200g / L of zinc sulfate, 200g / L of ammonium thiocyanate, 200g / L of ammonium nickel sulfate, and 150g / L of boric acid. The process parameters are temperature 25°C, Current density 2A / cm 2 .

Embodiment 2

[0025] Embodiment 2: The material of the plated part is an aluminum-based composite material with a silicon carbide content of 90%.

[0026] 1) The alkaline cleaning solution is an aqueous solution of sodium hydroxide 300g / L, and its process parameters are a temperature of 30°C and a time of 10s.

[0027] 2) The pickling solution is 100ml / L of nitric acid, 50ml / L of sulfuric acid, and 200g / L of chromic anhydride. The temperature is room temperature and the time is 20s.

[0028] 3) The black electroplating solution contains 20g / L of nickel sulfate, 100g / L of zinc sulfate, 200g / L of ammonium thiocyanate, and 100g / L of ammonium nickel sulfate. The electroplating process parameters are temperature 70°C, current density 0.1A / cm 2 .

Embodiment 3

[0029] Embodiment 3: The material of the plated part is an aluminum-based composite material with a silicon carbide content of 60%.

[0030] 1) The alkaline cleaning solution is an aqueous solution of sodium hydroxide 200g / L, and its process parameters are a temperature of 60°C and a time of 20s.

[0031] 2) The pickling solution is 200ml / L of nitric acid and 50ml / L of hydrofluoric acid. The temperature is room temperature and the time is 1 min.

[0032] 3) The black electroplating solution contains 100g / L of nickel sulfate, 40g / L of zinc sulfate, 80g / L of ammonium thiocyanate, 10g / L of methionine and 100g / L of triethanolamine. The electroplating process parameters are temperature 40°C, current density 0.5A / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com