High-dimension stable corrosion-resistant martensite steel and preparation method of steel structural material

A technology of dimensional stability and martensitic steel, applied in the field of metal materials, can solve the problems of poor mechanical properties and machining properties, poor wear resistance, poor toughness, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

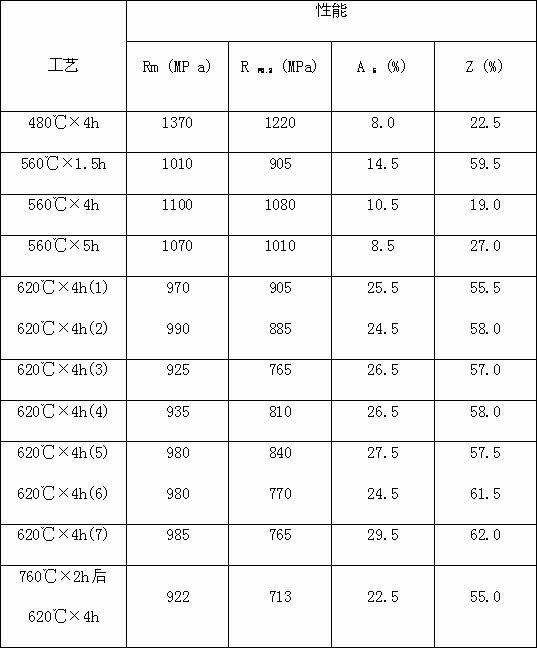

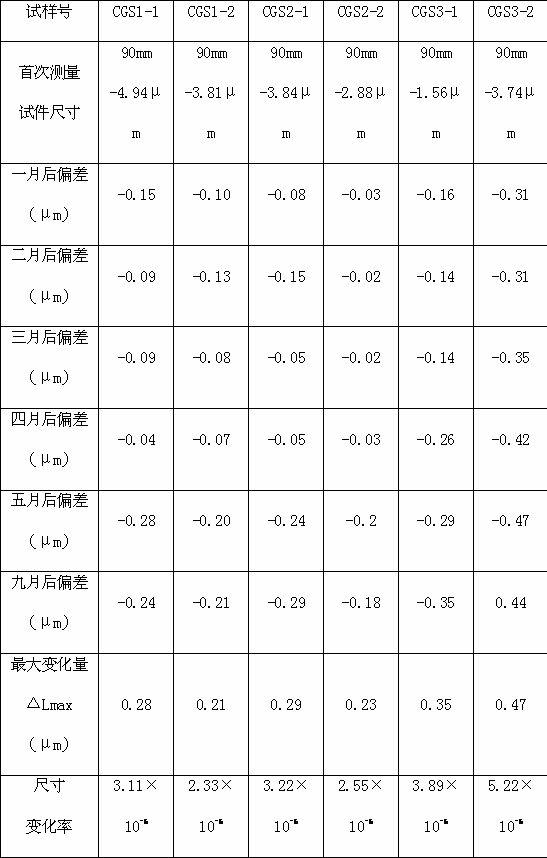

Examples

Embodiment 1

[0078] A corrosion-resistant martensitic steel with high dimensional stability, the chemical composition of which is: C: 0.025; Cr: 14.0; Ni: 5.49; Cu: 2.0; Nb: 0.2; Mn: 0.7; Mo: 0.3; Si: 1.0; P ≤ 0.0083; S ≤ 0.0081; the balance is Fe, which is vacuum smelted and then vacuum cast into precision castings, and machined into structural components for instruments with high dimensional stability.

[0079] The preparation method of the above-mentioned high dimensional stability and corrosion-resistant martensitic steel structural material is characterized in that it comprises the following steps:

[0080] 1) Weigh each component according to the weight percentage of each chemical component;

[0081] 2) Vacuum induction melting

[0082] Adding the components weighed in step 1 into a vacuum induction melting furnace for vacuum induction melting, the vacuum induction melting adopts a secondary refining process;

[0083] The first refining is at a temperature of (1530-1560) ±5°C, the ...

Embodiment 2

[0096] Others are the same as in Example 1, except that the steel ingots are first forged into square billets with cross-sectional side lengths of 40mm, 60mm, and 80mm, and then surface-finished and hot-rolled into round bars of φ8-φ14mm, which are also wire rod blanks.

[0097] Use flaw detection equipment to test the internal and external quality of the wire rod blank, and use a finishing device for finishing;

[0098] After surface finishing and hot rolling into φ8~φ14mm round wire bar blanks, after finishing and flaw detection, solution heat treatment is carried out at 1040±5°C, and heat preservation is carried out according to the thickness of the wire material; the deformation degree of the wire material is controlled At 40-65%, the deformation of finished silk is controlled at 30-40%;

[0099] The finished and flaw-detected wire rod blanks are further cold-processed into φ2mm, φ1mm, φ0.5 mm, and φ0.25 mm respectively to obtain high dimensional stability and corrosion-re...

Embodiment 3

[0103] Others are the same as embodiment 1, just that the blank of the plate and strip is forged into a width that is respectively 300 mm, 350 mm, 400 mm wide and 30 mm thick, to obtain the slab of the plate and strip;

[0104] Use flaw detection equipment to test the internal and external quality of the blank of the plate and strip, and use a finishing instrument for finishing;

[0105]The finished and flaw-detected plate and strip blanks are further cold-processed to obtain high-dimensional stability and corrosion-resistant martensitic steel structure materials.

[0106] The high dimensional stability and corrosion-resistant martensitic steel structure material is a hot-rolled plate, and the slab after finishing and flaw detection is hot-rolled at a temperature of (850-1160) ± 5°C to a width of 320-440 mm, 8 ~10 thick slabs; and then carry out solution treatment. The method of solution treatment is to hold the temperature for 30-60 minutes at a temperature of 1040±10°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com