Genetic engineering strain producing lipase and construction method thereof

A technology of genetic engineering strain and construction method, which is applied in the field of lipase-producing genetic engineering strain and its construction, can solve the problems of high price and high price of biodiesel, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: the cell of this embodiment produces lipase genetic engineering strain is ellipse, germinates and reproduces, forms ascospore; High lipase activity.

[0012] Pick a ring of lipase-producing genetically engineered strains in this embodiment, transfer them to the seed medium, place them on a shaker at 28°C and 180r / min for 24h, and obtain the seed solution; inoculate with 3% (v / v) Inoculate the seed solution into the fermentation medium, shake and culture at 28°C for 72 hours to obtain the fermentation liquid, centrifuge the fermentation liquid at 5000r / min and 4°C for 5min, and take the supernatant to obtain the crude enzyme liquid. The titration method was used to measure the crude enzyme liquid, and the lipase activity of the lipase-producing genetically engineered strain of this embodiment was 322.91-335.95 U / mL. The seed medium and fermentation medium are YPD medium.

specific Embodiment approach 2

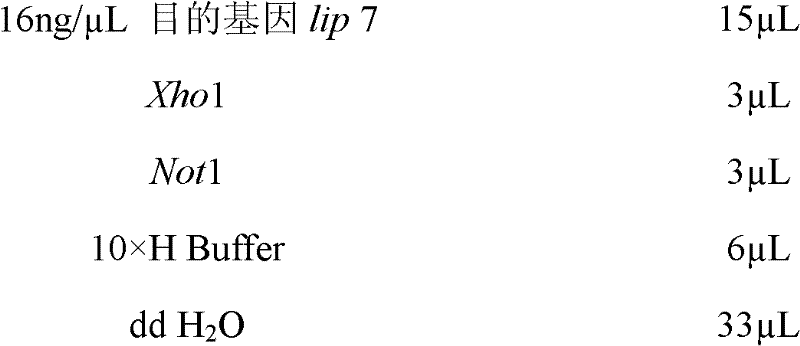

[0013] Specific embodiment two: the construction method of this embodiment produces lipase genetic engineering strain, carries out according to the following steps: 1, the extraction of lipase producing bacterial strain Yarrowia lipolytica HDY-76 genomic DNA: get 3mL Yarrow lipolytica The bacterial liquid of Saccharomyces cerevisiae HDY-76 was centrifuged at 12000r / min for 1min, the supernatant was discarded, and the genomic DNA of Yarrowia lipolytica HDY-76 was extracted according to the genomic DNA extraction kit of TIANGEN company; 2. The lip7 gene PCR amplification: Use the genomic DNA extracted in step 1 as a template to perform PCR amplification to obtain amplified products, which are detected by 1% agarose gel electrophoresis; the amplified products are purified using a gel recovery kit , the target gene lip7 was obtained, and the target gene lip7 was sequenced to verify its accuracy; 3. The construction of the recombinant expression vector pGAPHαM-lip7: the target gene ...

specific Embodiment approach 3

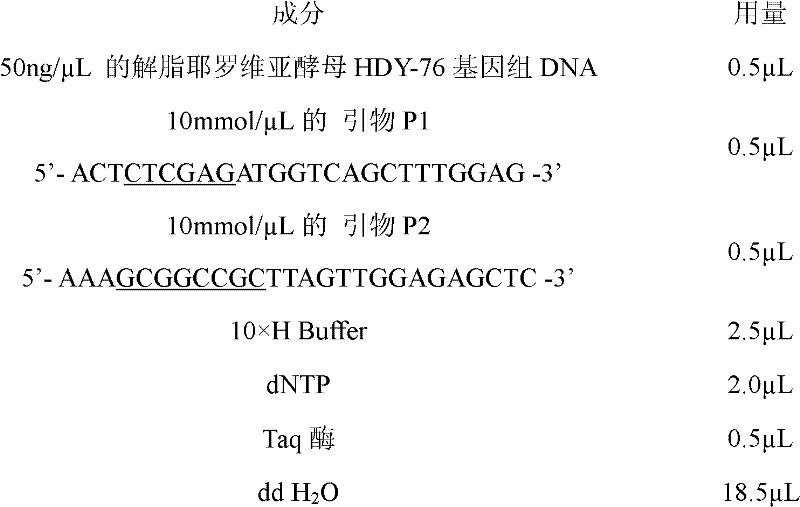

[0028]Specific embodiment three: the difference between this embodiment and specific embodiment two is: the reaction system of PCR amplification in step 2 is as follows:

[0029]

[0030] PCR amplification conditions were: 94°C pre-denaturation for 4 min, 94°C denaturation for 45 s, 58.5°C annealing for 30 s, 72°C extension for 80 s, a total of 32 cycles, 72°C extension for 10 min, and 4°C incubation. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com