Functional-material-based glucose biosensor and manufacturing method thereof

A technology of biosensor and glucose, which is applied in the field of biotechnology analysis and detection, can solve problems such as the interference of oxygen content changes, and achieve the effects of shortened response time, safe operation, and low-cost analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

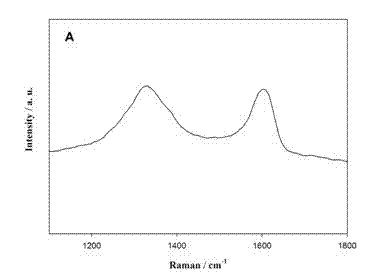

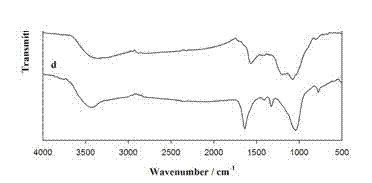

[0056] Preparation Example 1 Graphene Preparation

[0057] Modified Hummers method combined with hydrazine hydrate reduction method: first, graphite (1.5 g, 325 mesh) was added to 12 ml concentrated H 2 SO 4 , 2.5 g K 2 S 2 o 8 and 2.5 g P 2 o 5 In the mixture, heat the above mixed system to 80 o C, maintain this temperature, and magnetically stir for 5 hours. Then the reaction system was cooled to room temperature, and the mixture was poured into 500 ml of deionized water and left to stand overnight. Filter the above standing matter through a 0.2 micron filter membrane, wash and dry naturally to obtain pre-oxidized graphite. Add the pre-oxidized graphite to 0 o Concentrated H of C 2 SO 4 120 ml, then slowly add 15 g KMnO 4 , and control the reaction temperature at 20 o c Stir. Potassium permanganate was added, and the reaction system was controlled at 35 o C was stirred for 4 hours, then, 250 ml of deionized water was added, and the temperature was controlled...

preparation Embodiment 2

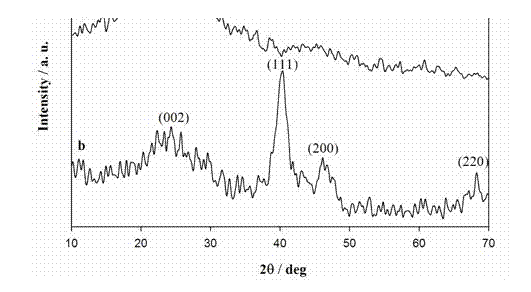

[0058] Preparation Example 2 Preparation of Graphene Nanomaterials (Palladium Nanoparticles / Graphene Composite Pd NPs / CSGR)

[0059] First, disperse 200 mg of graphene oxide into a mixed medium of 40 ml thionyl chloride and 1 ml N,N-dimethylformamide, sonicate at room temperature for 0.5 hours, and then reflux for 52 hours to prepare 219.2 mg of brown acid chloride compound . At the same time, mix 1.753 g of phthaloyl chitosan), 1.201 g of LiCl and 120 ml of N, N-dimethylacetamide, and 140 o C was reacted for 2 hours. After cooling the reaction system, 219.2 mg of the brown acid chloride compound prepared in the previous step and 14 ml of pyridine were added to the reaction system, and refluxed for 48 hours under nitrogen protection. After cooling, it was filtered, washed, and vacuum-dried. After drying, the solid was stirred in 120 ml of distilled water for 6 hours, filtered, and the retained solid was redispersed in 200 ml of water, ultrasonicated for 1 hour, filtered, and...

preparation Embodiment 3

[0063] Preparation Example 3 Sensor Working Electrode Preparation

[0064]Grind the glassy carbon electrode with 1200# metallographic sandpaper first, and then use 1 μm, 0.3 μm, 0.05 μm Al 2 o 3 Polished, rinsed with distilled water, in 1:1 HNO 3 Ultrasonic cleaning with aqueous solution, absolute ethanol, and distilled water for 5 min each, and drying at room temperature for later use. Take 2 mg of the nanoparticle-functionalized graphene material prepared above, and disperse it in 1 ml of 5% acetic acid. After ultrasonication, take 8 μL of the above-mentioned dispersion solution and drop it on the surface of the above-mentioned glassy carbon electrode. After drying, the nanoparticle-functionalized graphene material is obtained. Graphene material modified electrodes. The electrode was soaked with 0.5% glutaraldehyde solution at room temperature, then washed with deionized water and dried at room temperature. Drop 8 μL of 4 mg / ml glucose oxidase (GOD) solution on the nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com