Anode material with lithium ferrous phosphate being embedded in stereoscopic reticular electric conductor and preparation method thereof

A lithium iron phosphate, three-dimensional mesh technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem that the overall performance of the battery is not optimal, and achieve superior processing performance, good safety, compact density and pressure. High solid density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

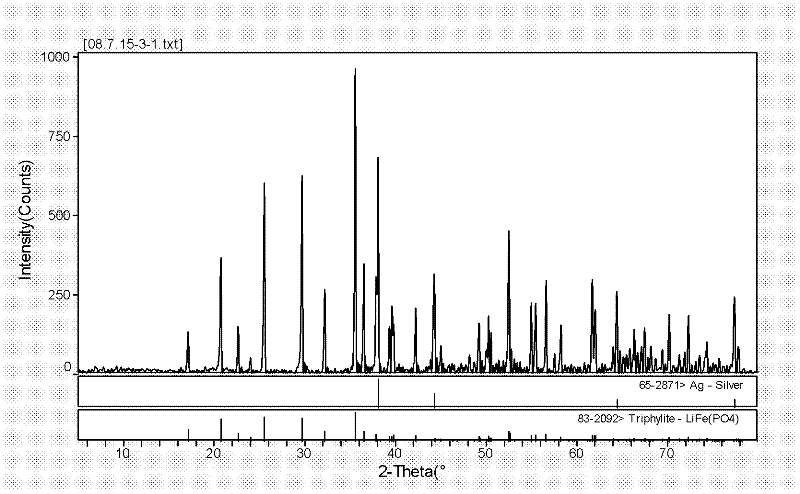

[0036] Get 70 grams of solution containing 6.8 grams of lithium bicarbonate and mix and stir with 7.1 grams of phosphorus pentoxide, add 21.8 grams of ferrous sulfate with a purity of 99.5% in the above solution and mix and stir, and mix with 0.05 grams of highly conductive silver The slurry is fully mixed, sheared, and dispersed, and the above homogeneous solution is evaporated and crystallized into pellets in a crystallizer with a high-speed stirrer. The stirring speed is 2800 rpm and the temperature is 110°C to make precursor spherical particles of about 15 microns. Get wherein 6 grams of precursor spherical particles and move into the quartz boat in the tube furnace, feed high-purity nitrogen in the tube furnace, feed acetylene gas when the furnace temperature rises to 600 °C, the flow rate of acetylene gas is 20 ml / min, Keep warm for 5 hours. Raise the temperature of the furnace to 800°C and keep it warm for 16 hours. After cooling to room temperature, samples are taken f...

Embodiment 2

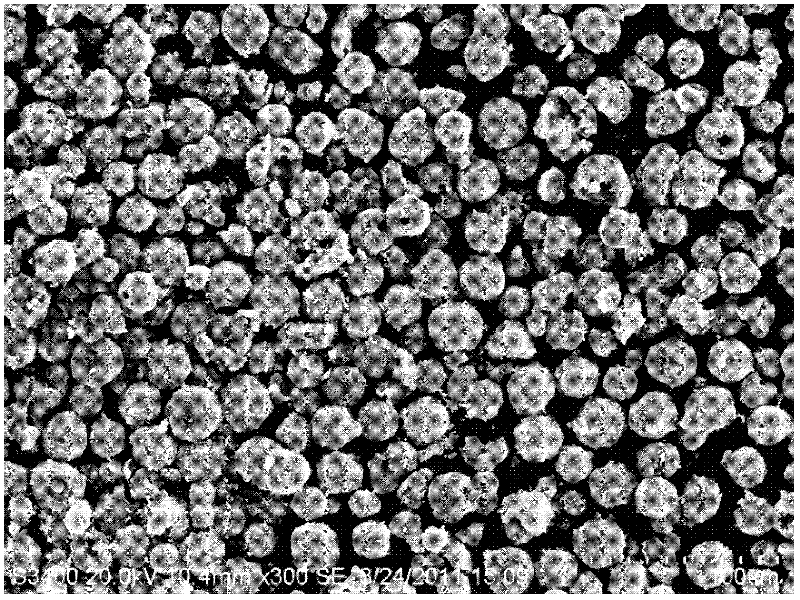

[0038]Dissolve 10.39g of lithium dihydrogen phosphate in 200mL of deionized water, add 17.99g of ferrous oxalate, and then add 2g of polyvinyl alcohol, mix thoroughly in a grinder, disperse and grind for 3 hours, and place in a crystallizer with a high-speed stirrer For pelletizing, the stirring speed is 2800 rpm and the temperature is 120° C. to obtain a spherical precursor with an apparent particle size of 10-20 μm. Move the precursor body into a tube furnace, feed high-purity nitrogen into the tube furnace, and feed ethylene gas when the furnace temperature rises to 600 °C, the flow rate of ethylene gas is 15 mL·min-1, and the heating time is 3 hours, and the furnace temperature is raised to 800°C and heat preservation for 8 hours, after cooling to room temperature, samples were taken to measure the charge and discharge performance of the material, the average capacity (0.2C) of 100 charge and discharge was 149mAh / g. Observing the morphology of the above-mentioned materials...

Embodiment 3

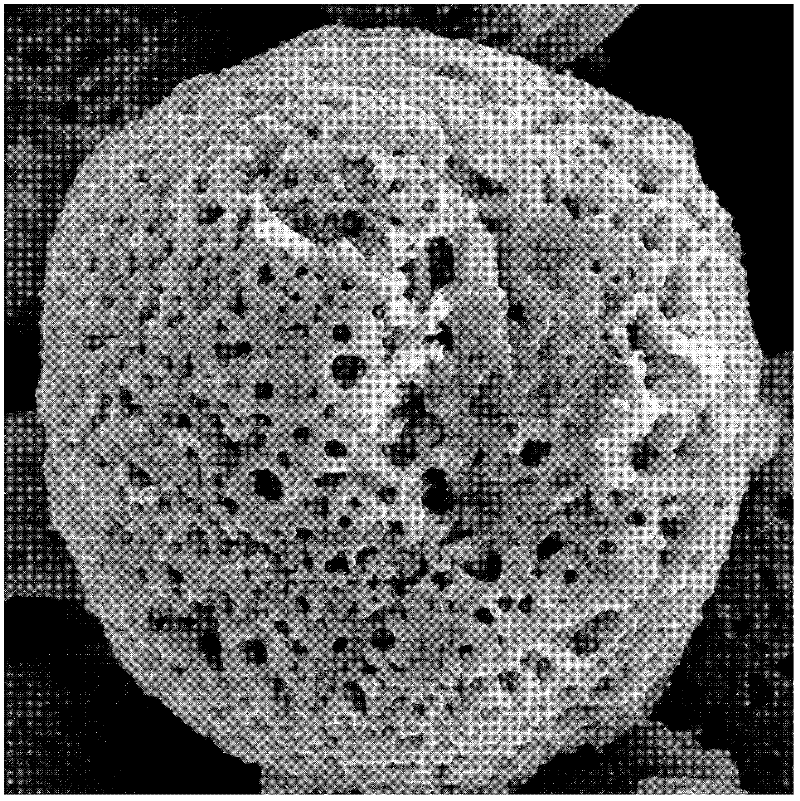

[0040] Dissolve 4.20 g of lithium hydroxide monohydrate in 200 mL of distilled water, stir and mix with 11.53 g of 85% phosphoric acid, add 7.99 g of ferric oxide, then add 2 g of sucrose, mix, grind, shear and disperse into a uniform body, and The above-mentioned emulsion is sprayed and pelletized with a spray pelletizer. The inlet temperature of the spray solidification pelletizer is 350° C., and the outlet temperature is 90° C. to make micron-sized precursor spherical particles. Take the above-mentioned precursor and move it into the quartz boat in the tube furnace, pass high-purity nitrogen into the tube furnace, raise the furnace temperature to 550°C and keep it for 3 hours, then raise the furnace temperature to 800°C and keep it for 8 hours, then cool to room temperature After sampling, use a scanning electron microscope to observe the morphology of the spherical positive electrode material in which the above-mentioned nano-lithium iron phosphate grains are embedded in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com