Oxadiargyl oil suspension agent and preparation method thereof

A technology of oxadiazone and oil suspension agent, which is applied in the field of pesticides and can solve the problems of dust pollution, difficulty in weighing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 200g propargyl oxadiazone technical material, 8g lignosulfonate dispersant, 13g thickener organic bentonite, white carbon black, magnesium aluminum silicate or a mixture of several, 15g stabilizer epoxy soybean oil , 190g of emulsifier styrene-based polyoxyethylene ether and alcohol ether mixture, 574g of soybean oil are mixed evenly and then put into the sand mill, sand milled until the particle size is below 5um, and the sand milled product is filtered out.

Embodiment 2

[0022] Take by weighing 200g propargyl oxadiazone former drug, 10g ethylenediamine polyoxyethylene polyoxyethylene ether dispersant, 16g thickener organic bentonite, white carbon black mixture, 20g stabilizer hydroquinone, 250g emulsifier benzene Vinyl polyoxyethylene ether and alcohol ether mixture, 504g of methyl esterified corn oil are evenly mixed and placed in a sand mill, sanded to a particle size below 5um, and the sanded product is filtered out.

Embodiment 3

[0024] Weigh 200g propargyl oxadiazone technical substance, 15g carboxylate dispersant, 13g thickener organic bentonite, magnesium aluminum silicate mixture, 18g stabilizer epoxy soybean oil, 280g emulsifier alkylphenol polyoxyethylene ether Formaldehyde condensate, phosphite mixture, 474g methyl oleate.

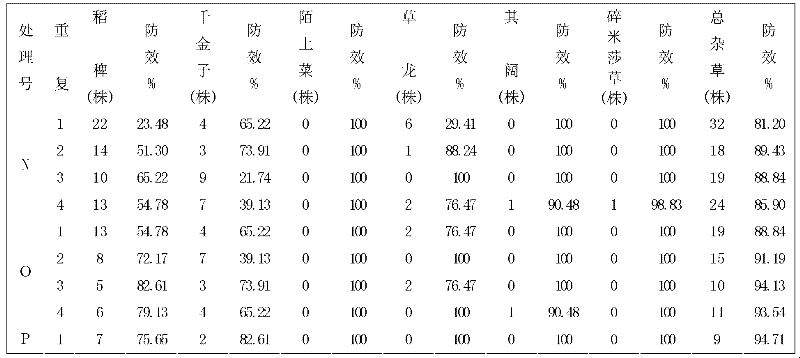

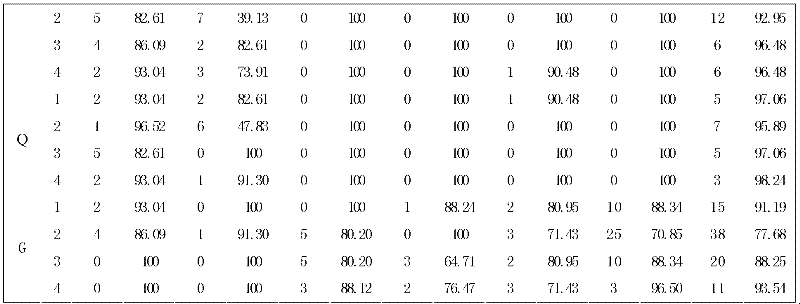

[0025] Field trial design and arrangement

[0026] 1 potion

[0027] 1.1 Test drug

[0028] 25% propargyl oxadiazone oil suspension concentrate, produced by Anhui National Pesticide Formulation Engineering Technology Center and Anhui Kelihua Chemical Co., Ltd.

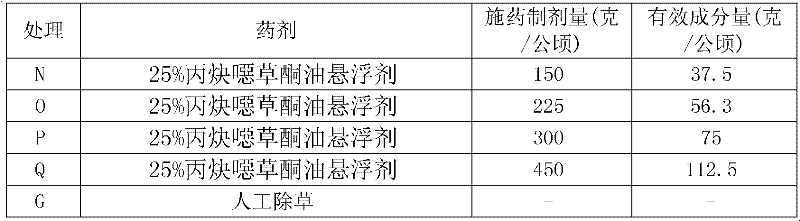

[0029] 1.2 Experimental Design of Drugs to be Tested

[0030] Table 1 Test design for test agents

[0031]

[0032] 1.3 Cell area and repetition

[0033] Community area: 20m 2

[0034] Number of repetitions: 4 times

[0035] 2 Application method

[0036] 2.1 How to use

[0037] After inhaling the correct dose of medicine, first add water to the small beaker and shake it well, then pour it into the manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com