Preparation method of polymer mixed network-based polymer dispersed liquid crystal (PDLC) film material

A technology of dispersing liquid crystals and hybrid networks, applied in the field of preparation of UV-induced polymerization-induced phase separation (PIPS), to overcome volume shrinkage, increase polymerization strength, and improve photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

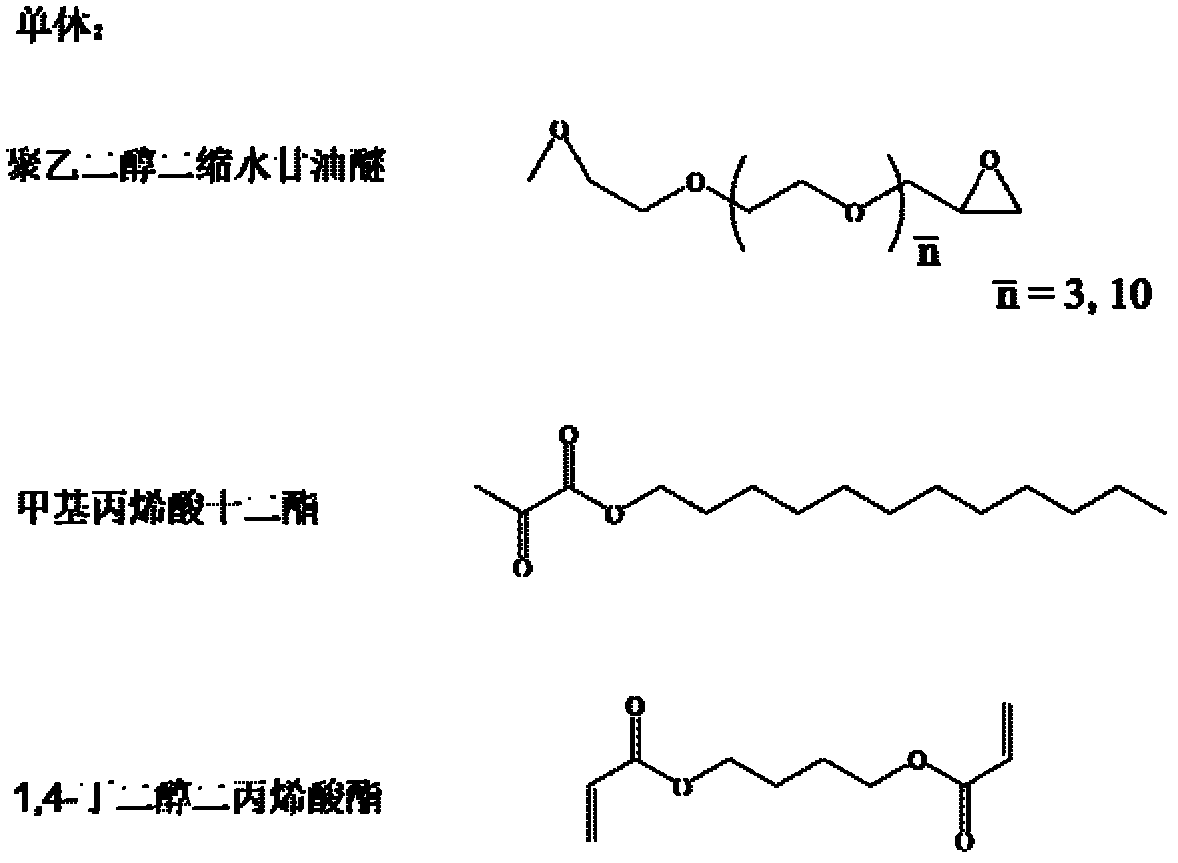

[0036] The selected UV-polymerizable epoxy monomer is polyethylene glycol diglycidyl ether (EGDE, =3 and 10), and two monomers with different chain lengths are mixed evenly at a mass ratio of 10:1 to form a UV Cationic polymerization monomer system; the selected UV-polymerizable acrylate (or methacrylate) monomers are lauryl methacrylate (LMA) and 1,4-butanediol diacrylate (BDDA). The two monomers are uniformly mixed at a mass ratio of 4:1 to form a UV radical polymerization monomer system. The above-mentioned UV-polymerizable cationic and radical-polymerizable monomer systems were mixed at a mass ratio of 6:1, and the mixed system was used as a UV-polymerizable monomer. The nematic phase liquid crystal that the present invention selects is SLC1717 (T NI =365.2K, n o =1.519, n e=1.720), and the mass ratio of the above-mentioned mixed ultraviolet light polymerization monomer system and liquid crystal is 3:2, and the isotropic liquid is formed at room temperature (20°C). Add...

Embodiment 2

[0041] The selected UV-polymerizable epoxy monomer is polyethylene glycol diglycidyl ether (EGDE, =3 and 10), and two monomers with different chain lengths are mixed evenly at a mass ratio of 10:1 to form a UV Cationic polymerization monomer system. The nematic phase liquid crystal that the present invention selects is SLC1717 (T NI =365.2K, n o =1.519, n e =1.720), and the above-mentioned UV cationic polymerization monomer system and liquid crystal are mixed uniformly at a mass ratio of 3:2 to form an isotropic liquid at room temperature (20°C). A cationic photoinitiator (UVI-6976) was added at 5.0wt% of the total mass, and 20 μm glass beads were added to control the thickness of the PDLC film. The content of glass beads was 0.5wt% of the total mass of the mixed system. After mixing the liquid crystal, ultraviolet cationic polymerization monomer, photoinitiator and glass microspheres evenly, it is coated on the middle of two plastic films coated with indium tin oxide (ITO)...

Embodiment 3

[0045] The selected UV-polymerizable acrylate (or methacrylate) monomers are lauryl methacrylate (LMA) and 1,4-butanediol diacrylate (BDDA). Mix evenly at a ratio of 4:1 to form a UV radical polymerization monomer system. The nematic phase liquid crystal that the present invention selects is SLC1717 (T NI =365.2K, n o =1.519, n e =1.720), and the mass ratio of the above-mentioned ultraviolet light radical polymerization monomer system and liquid crystal is 3:2, and the isotropic liquid is formed at room temperature (20°C). Add 5.0wt% of the total mass of free radical photoinitiator (TPO), and add 20 μm glass beads to control the thickness of the PDLC film. The content of glass beads is 0.5wt% of the total mass of the mixed system. After mixing the liquid crystal, ultraviolet radical polymerization monomer, photoinitiator and glass beads evenly, it is coated on the middle of two plastic films coated with indium tin oxide (ITO) transparent conductive film, and the film is uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com