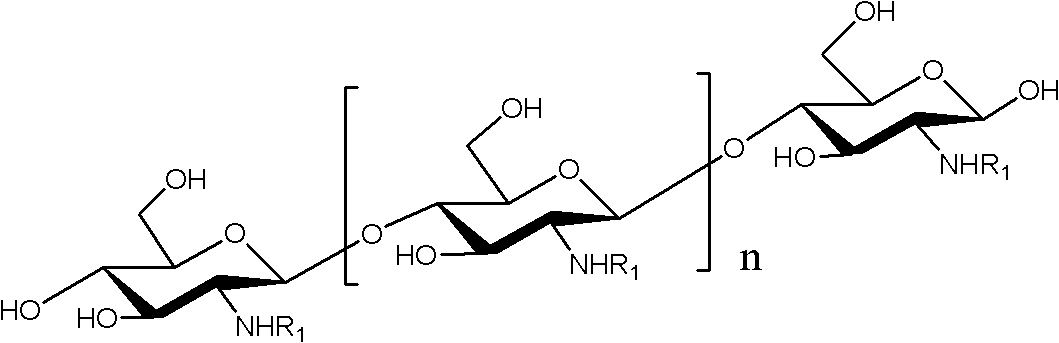

N-unsaturated fatty acid acylated chitosan oligosaccharide and preparation and application thereof

A technique for acylating chitosan oligosaccharide and unsaturated fatty acid with fatty acid, which is applied in the field of N-unsaturated fatty acid acylating chitooligosaccharide and its preparation, and can solve the problems of troublesome use and storage, insufficient stability of unsaturated fatty acid, insufficient activity, etc., To achieve the effect of mild conditions, simple operation process and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of N-linoleic acid acylated chitosan oligosaccharide (ammonolysis method):

[0032] Dissolve 2.8g of linoleic acid in N,N-dimethylformamide (DMF), add 2.7g of p-nitrophenol, stir, add 0.1g of dimethylaminopyridine, dropwise add 2.06g of dicyclohexylcarbodiene Dissolve the imine in 5mL of DMF, react under heating conditions at 60-70°C for 2-6 hours after dripping, filter, pour the filtrate into ice water, precipitate white crystals, filter, and recrystallize with absolute ethanol to obtain linoleic acid p-Nitrophenyl ester 2.0g, aminolysis of ester:

[0033] Get 1.28g (3.2mmol) of p-nitrophenyl linoleate and dissolve it in 30mL of anhydrous dimethyl sulfoxide, and add 0.6g (3.1mmol) of chitosan oligosaccharide with a degree of polymerization of 2-8 (the mole of ester and oligosaccharide The ratio is 1-2:1 (calculated according to the glucosamine residue in chitosan oligosaccharide), react at 60-70°C for 4 hours, add ether / acetone solution 5...

Embodiment 2

[0036] Embodiment 2: the preparation of N-linoleic acid acylated chitosan oligosaccharide (one-step method)

[0037] Take 1.62g of chitosan oligosaccharide with a degree of polymerization of 2-15 and dissolve it in 30mL of N,N-dimethylformamide, then add 0.1g of dimethylaminopyridine, add 4mL of methanol; take 3.0g of linoleic acid and dissolve it in Add N,N-dimethylformamide to the above solution; after reacting at 60°C for 4 hours, add 5 times the volume of ethanol to the reaction solution to produce a large amount of yellow precipitate, suction filter, and filter the cake with anhydrous Wash with acetone for 3 times to obtain a yellow powder, which is vacuum-dried to obtain N-linoleic acid acylated chitosan oligosaccharide powder as a solid. The infrared data are identical or substantially identical to Example 1. The degree of substitution was determined to be 71% by nuclear magnetic resonance.

Embodiment 3

[0038] Embodiment 3: the preparation of N-eicosapentaenoic acid acylated chitosan oligosaccharide (one-step method)

[0039]Take 1.62g chitosan oligosaccharide and dissolve it in 30mL of N,N-dimethylformamide, then add 0.1g of dimethylaminopyridine, add 4mL of methanol; take 3.5g of linoleic acid and dissolve it in N,N-dimethylformamide Formamide was added to the above solution; after reacting at 60°C for 4 hours, 5 times the volume of ethanol was added to the reaction solution to produce a large amount of light yellow precipitate, which was filtered by suction, and the filter cake was washed 3 times with anhydrous acetone to obtain Yellow powder, vacuum-dried to obtain N-eicosapentaenoic acid acylated chitosan oligosaccharide powder solid. Infrared spectrum (KBr) main absorption peak (IRu, cm -1 ): 3580~3390 (OH, NH); 3095 (HC=CH) 2939; 2860 (CH+CH 2 ); 1705 (C=C); 1685 (amide-I band); 1650 (amide-II band); 1116, 1054, 1033 (C-O); 891 (β, C-H). Same; The degree of substitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com