Solvent-free type epoxy zinc rich primer and preparation method thereof

An epoxy zinc-rich primer, solvent-free technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve problems such as potential safety hazards, achieve long anti-corrosion years, no pollution to the environment, and reduce volatile pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

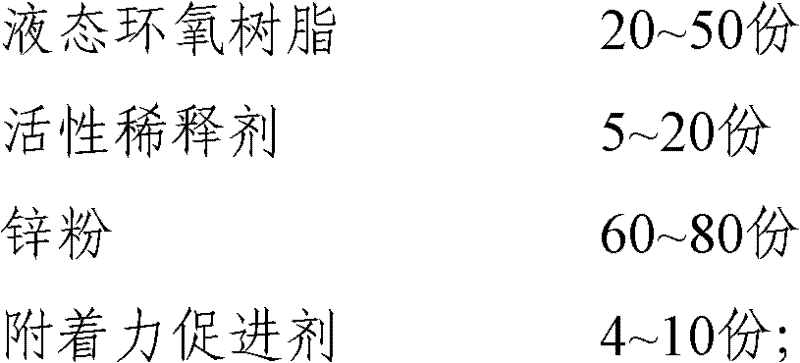

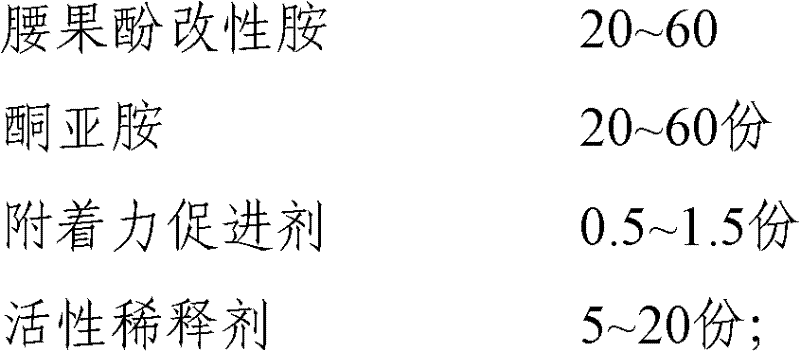

Method used

Image

Examples

Embodiment 1

[0032] Preparation of component A: liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM618) 20Kg, vinyl bishard amide 0.5Kg, glycidyl neodecanoate (Hebei Siyou Excellence Technology Co., Ltd. ShigenaTM10) 5Kg, polyamide Disperse 0.5Kg of wax and 60Kg of zinc powder until the fineness is below 50 microns, heat to 60°C, keep warm for 30 minutes, and finally put in 4Kg of 2,4,6-tris(dimethylaminomethyl)phenol, 2-(4-thiazole base) benzimidazole 0.5Kg, BYK-066N0.2Kg dispersed evenly to obtain A component;

[0033] Preparation of component B: Add cardanol formal diethylenetriamine 20Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 20Kg, 2,4,6-tris(dimethylamino Methyl) phenol 0.5Kg, glycidyl neodecanoate 5Kg, stir well, get B component;

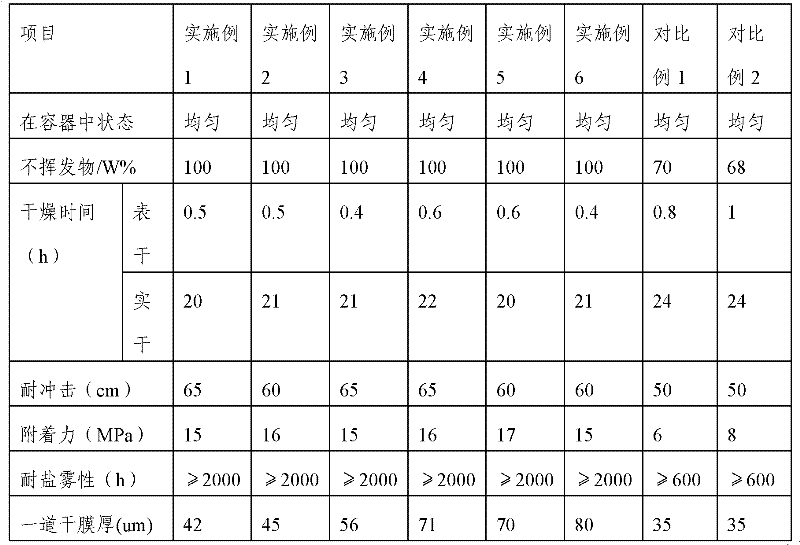

[0034] Take 9Kg A component and 2Kg B component and mix evenly for testing, the results are shown in Table 1.

Embodiment 2

[0036] Preparation of component A: liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM828) 50Kg, monoglyceride stearate 1.5Kg, trimethylolpropane triglycidyl ether 20Kg, polyamide wax 1.5Kg, zinc powder 80Kg Disperse until the fineness is below 50 microns, heat to 70°C, keep warm for 30 minutes, and finally put in 10Kg of 2,4,6-tris(dimethylaminomethyl)phenol, 1.5Kg of benzimidazole methyl carbamate, polydimethyl 0.5Kg of base siloxane is uniformly dispersed to obtain component A;

[0037] Preparation of component B: Add cardanol formal diethylenetriamine 60Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 60Kg, 2,4,6-tris(dimethylamino Methyl) phenol 1.5Kg, glycidyl neodecanoate 20Kg, stir well, get B component;

[0038] Take 11Kg A component and 2Kg B component and mix evenly for testing, the results are shown in Table 1.

Embodiment 3

[0040] Preparation of A component: liquid epoxy resin (Jiangsu Sanmu Group Co., Ltd. SM618) 35Kg, vinyl bishard amide 1Kg, trimethylolpropane triglycidyl ether 15Kg, polyamide wax 1Kg, flaky zinc powder ( The particle size is 400 mesh) 70Kg dispersed until the fineness is below 50 microns, heated to 60°C, kept for 60 minutes, and finally put in 2,4,6-tris(dimethylaminomethyl)phenol 5Kg, benzimidazole carbamic acid methyl 1Kg of ester and 0.35Kg of BYK-066N are uniformly dispersed to obtain component A;

[0041] Preparation of component B: Add cardanol formal diethylenetriamine 30Kg, benzophenone imine (Nanjing Aike Pharmaceutical Technology Co., Ltd.) 40Kg, 2,4,6-tris(dimethylamino Methyl) phenol 1Kg, cresyl glycidyl ether 16Kg, stir well, get B component;

[0042] Take 10Kg A component and 2Kg B component and mix evenly for testing, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com