Selenium nano-sensing material and preparation method thereof

A sensing material, selenium nanotechnology, which is applied in the field of inverse microemulsion synthesis of silica sensing materials, can solve problems such as measurement interference, and achieve the effects of simple operation, uniform and stable products, and safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

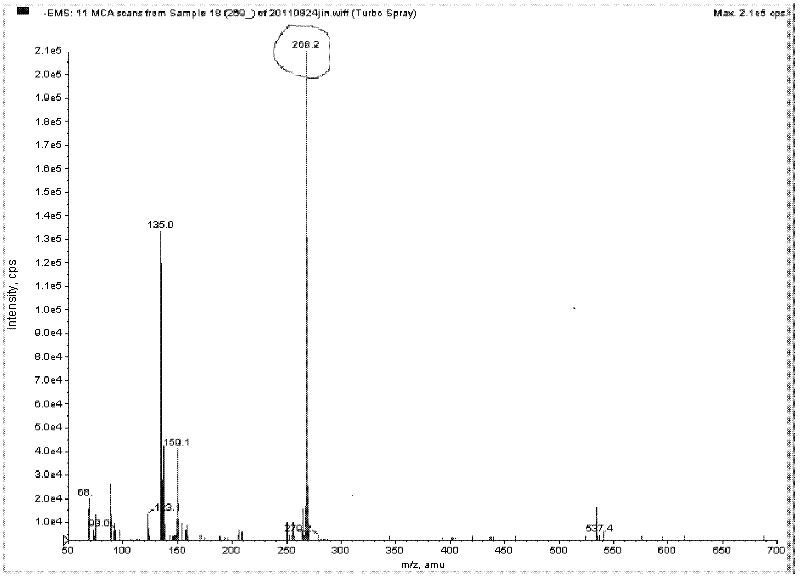

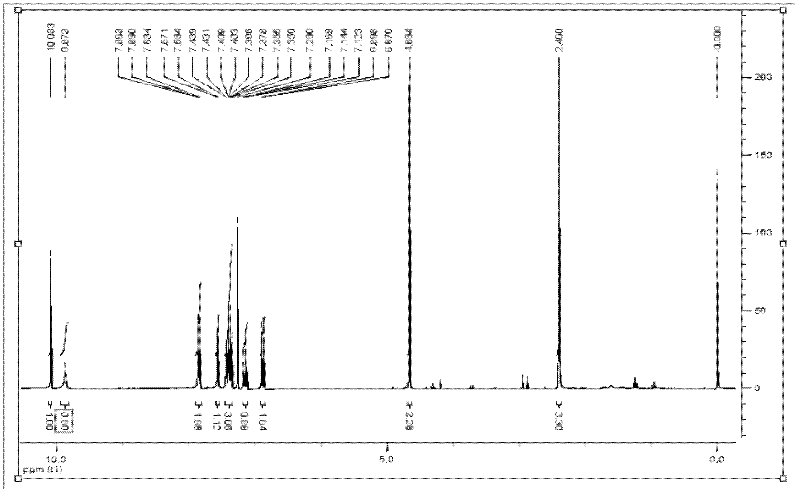

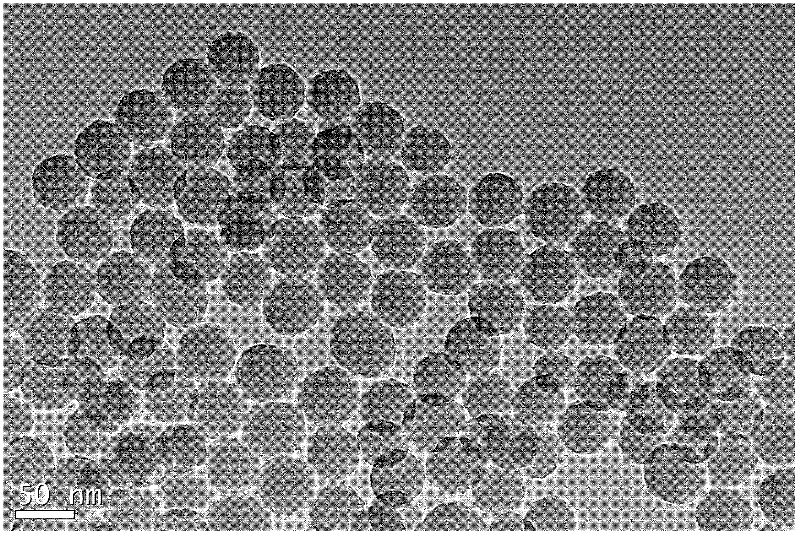

[0026] Preparation and characterization of embodiment 1 embedded Se nano-sensing material

[0027] (a) Synthetic N-phenyl-2-chloroacetamide (I)

[0028] Starting material aniline reacts with chloroacetyl chloride to generate compound N-phenyl-2-chloroacetamide (I)

[0029]

[0030] Specifically, 453 μL (5 mmol) of aniline, 140 μL of triethylamine, and 30 mL of solvent-dried dichloromethane were added to a 100 ml round bottom flask. Under the condition of ice bath, 397μL (5mmol) of chloroacetyl chloride was added dropwise into the reaction system at the rate of two drops per second with a constant pressure dropping funnel, stirred at room temperature for 12 hours, and mixed with mass concentration of 10% HCl and saturated saline Washed three times each, anhydrous Na 2 SO 4 Dry overnight, use petroleum ether by volume: ethyl acetate=5:1 developer column chromatography, as a result, white solid N-phenyl-2-chloroacetamide is obtained, and the yield is about 90%

[0031] (b) S...

Embodiment 2

[0044] Changing the amount of dichloromethane used in step (a) of Example 1 to 22.65mL-36.24mL, and the rest being the same as in Example 1, the embedded Se nano-sensing material of the present invention can also be obtained.

Embodiment 3

[0046] Change the consumption of the extraction solvent of (b) step in embodiment 1, ethyl acetate and water are each 80 milliliters, all the other are the same as embodiment 1, also can make the embedded Se nanometer sensing material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com