Method for preparing ethylene and propylene through catalytic cracking

A catalytic cracking, ethylene technology, applied in the direction of catalytic cracking, hydrocarbon cracking to hydrocarbon production, and cracking, etc., can solve the problems of easy coking, frequent regeneration, and short service cycle of the catalyst, so as to facilitate recovery or reuse, and enhance the mass transfer process. , the effect of simplifying the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material is the C5 mixed hydrocarbon without diolefins from the Shanghai Petrochemical Research Institute of Chemical Industry. Its composition is (wt%):

[0038] Isopentane 6.79, n-pentane 46.12, trans-2-pentene 8.60, 1-pentene 7.75,

[0039] 2-methyl-2-butene 7.17, 2-methyl-1-butene 17.33, cis-2-pentene 5.07.

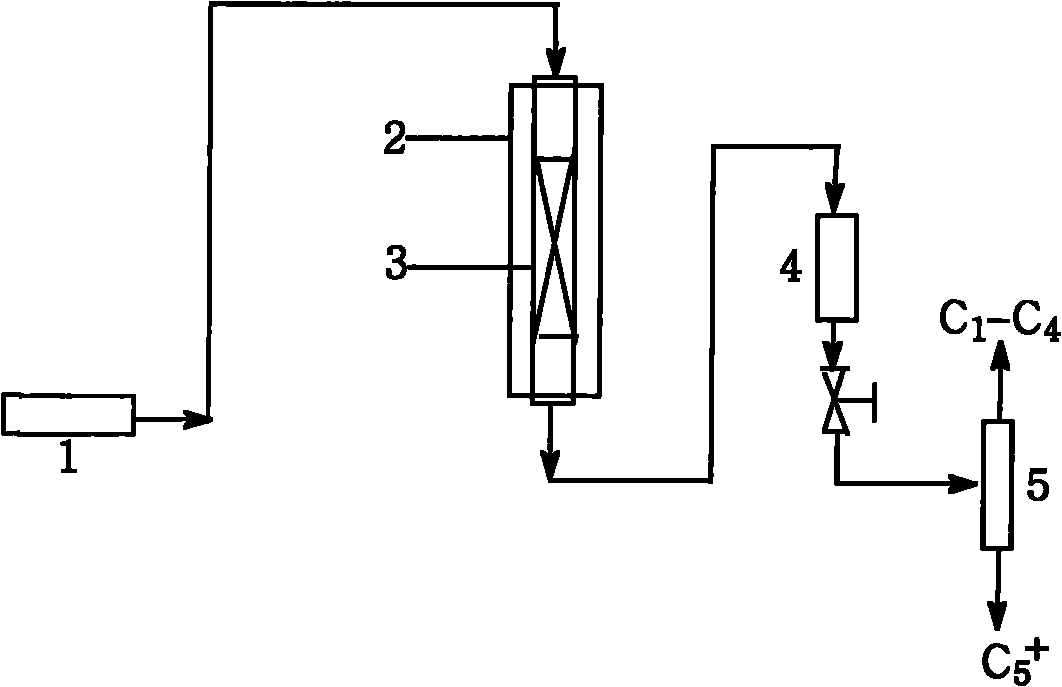

[0040] 0.3g ZSM-5 zeolite (SiO 2 / Al 2 O 3 The molar ratio is 200, the average particle size is 30nm) is added to 1kg carbon five mixed hydrocarbon, the catalyst content is 300ppm, and it enters the fixed bed reactor 3 through the peristaltic pump 1 under stirring; the pressure is 0.1MPa, the temperature is 550℃, and the volume hourly space velocity is 5h -1 Under the reaction. After the reaction product is cooled and separated by the cooler 4 and the gas-liquid separator 5, the volume of the gas phase is measured with a wet gas flow meter, and the liquid phase product is collected with an Erlenmeyer flask. After standing still, the supernatant liquid is poure...

Embodiment 2

[0044] Taking the naphtha used in the Yanshan Petrochemical Ethylene Plant as the raw material, the distillation range of naphtha is 32-156℃, and the composition is as follows (wt%):

[0045] Carbon five is 1.73, carbon six is 19.01, carbon seven is 24.25, carbon eight is 28.65, carbon nine is 19.20, carbon ten is 5.51, carbon eleven is 1.40, and carbon twelve is 0.26.

[0046] 0.3g ZSM-5 zeolite (SiO 2 / Al 2 O 3 The molar ratio is 200, the average particle size is 100nm) added to 1kg naphtha, the catalyst content is 300ppm, the pressure is 0.1MPa, the temperature is 650℃, and the volume hourly space velocity is 5h -1 The reaction was carried out under the conditions of, and the other steps were the same as in Example 1. The composition of the main products in the gas phase is listed in Table 1.

Embodiment 3

[0051] Using light diesel oil from Yanshan Petrochemical Refinery as raw material, its distillation range is 193-384℃, and its composition is as follows (wt%):

[0052] Paraffins 59.7, cycloalkanes 30.3, aromatics 10.0.

[0053] 0.2g mordenite (SiO 2 / Al 2 O 3 The molar ratio is 30, the average particle size is 200nm) Add 1kg light diesel oil, the catalyst content is 200ppm, the pressure is 0.1MPa, the temperature is 650℃, the volume hourly space velocity is 5h -1 The reaction was carried out under the conditions of, and the other steps were the same as in Example 1. The composition of the main products in the gas phase is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com