Pig-raising fermentation bacterial agent for biological and environment-friendly fermentation bed and preparation method thereof

A fermenting agent, bio-environmental protection technology, applied in the field of microbial engineering, can solve the problems of deteriorating external breeding environment, complex use and operation of fermenting agents, and increased incidence of pigs, so as to reduce drug resistance and drug residues, and reduce the breeding opportunities of mosquitoes and flies , the effect of inhibiting tumor cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

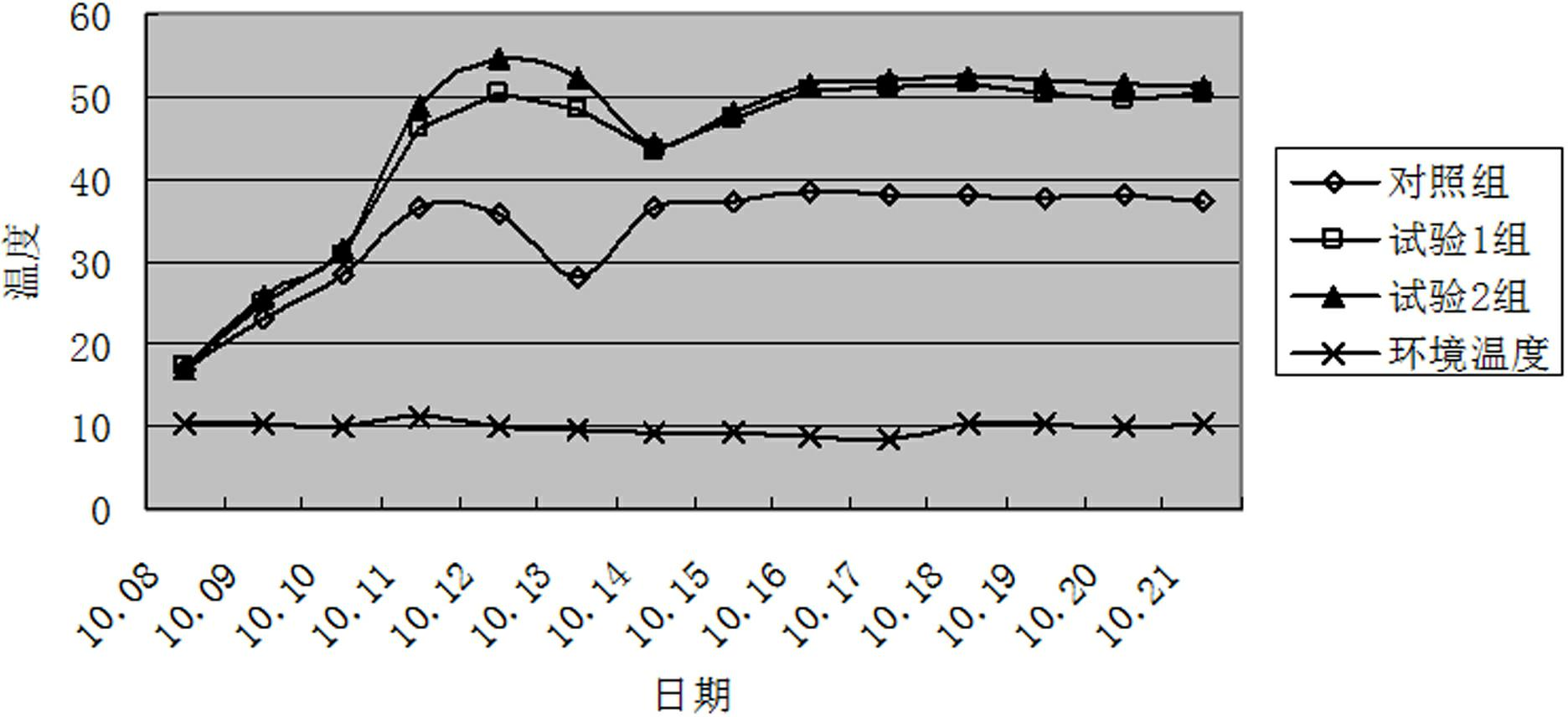

Image

Examples

Embodiment 1

[0055] a. Activation of bacteria

[0056] Take 10ml of normal saline with a volume percentage of 0.9%, put it in seven 250ml Erlenmeyer flasks, inactivate at 121°C for 30 minutes, then cool to 30°C, pour the seven strains into Put it into the above-mentioned 7 250ml Erlenmeyer flasks with physiological saline, after shaking and dissolving, let it rest in a 30°C incubator for 30 minutes, and set aside;

[0057] b. Preparation of primary bacterial agent

[0058] Measure 200ml of the culture medium of seven strains of bacteria respectively, place them in seven 500ml Erlenmeyer flasks, inactivate at 121°C for 30 minutes, cool to 30°C, inoculate the activated strains in step 2, and inoculate them at 30- Cultivate at constant temperature on a shaker at 35°C (150r / min) for 48 hours, and use it as a first-class strain fermentation agent;

[0059] c. Preparation of fermented bacteria for production

[0060] First prepare 7 parts of 10% skimmed milk emulsion (4000ml each), t...

Embodiment 2

[0068] The difference from Example 1 lies in the preparation of composite microbial agent and the production of fermented mattress material,

[0069] Preparation of composite bacterial agent: according to the weight of powder freeze-dried strains, get morel powder 20g, Bacillus stearothermophilus 1.1923 powder 50g, Bacillus subtilis powder 40g, Bacillus stearothermophilus 1.1866 powder 40g parts, Anand's chain Mix 30g of mold powder, 30g of bifidobacterium thermoacidophilus powder, and 50g of saccharomyces cerevisiae 2.2081 powder, mix well and pack in vacuum to obtain the composite microbial agent.

[0070] Production of fermented mattress material:

[0071]With 1.5% of corn, 28.5% of rice husk (not pulverized), 50% of sawdust, and 20% of stalk pulverized matter are fermentation bed material (substratum), and the compound bacterial agent of the present invention is pressed by 20 grams / m 2 After dissolving in 2000ml of warm water at 45°C, spray it on the surface of the litter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com