Dental implant and preparation method thereof

A dental implant and implant technology, applied in dental preparations, dental prostheses, dentistry, etc., can solve problems such as cumbersome steps, achieve the effect of increasing the rate of osseointegration, shortening the time of osseointegration, and improving the success rate of implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Select pure titanium to process it into a dental implant matrix. After the surface of the dental implant matrix is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes, and then dried for use;

[0036] 2) Configure the electrolyte solution for the micro-arc oxidation process: deionized water is used as the solvent, and the solute is 0.04M β-sodium glycerophosphate and 0.2M calcium acetate;

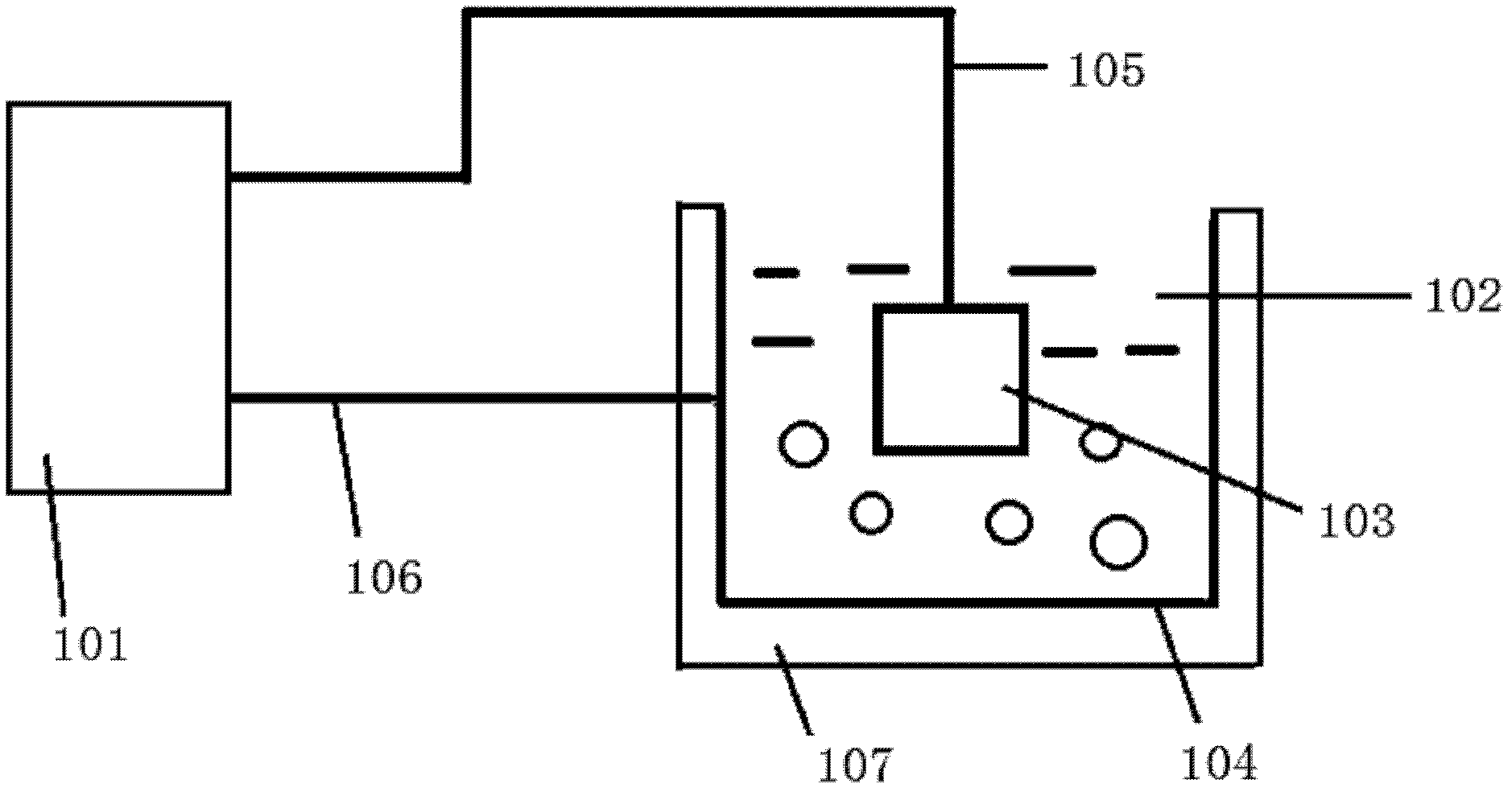

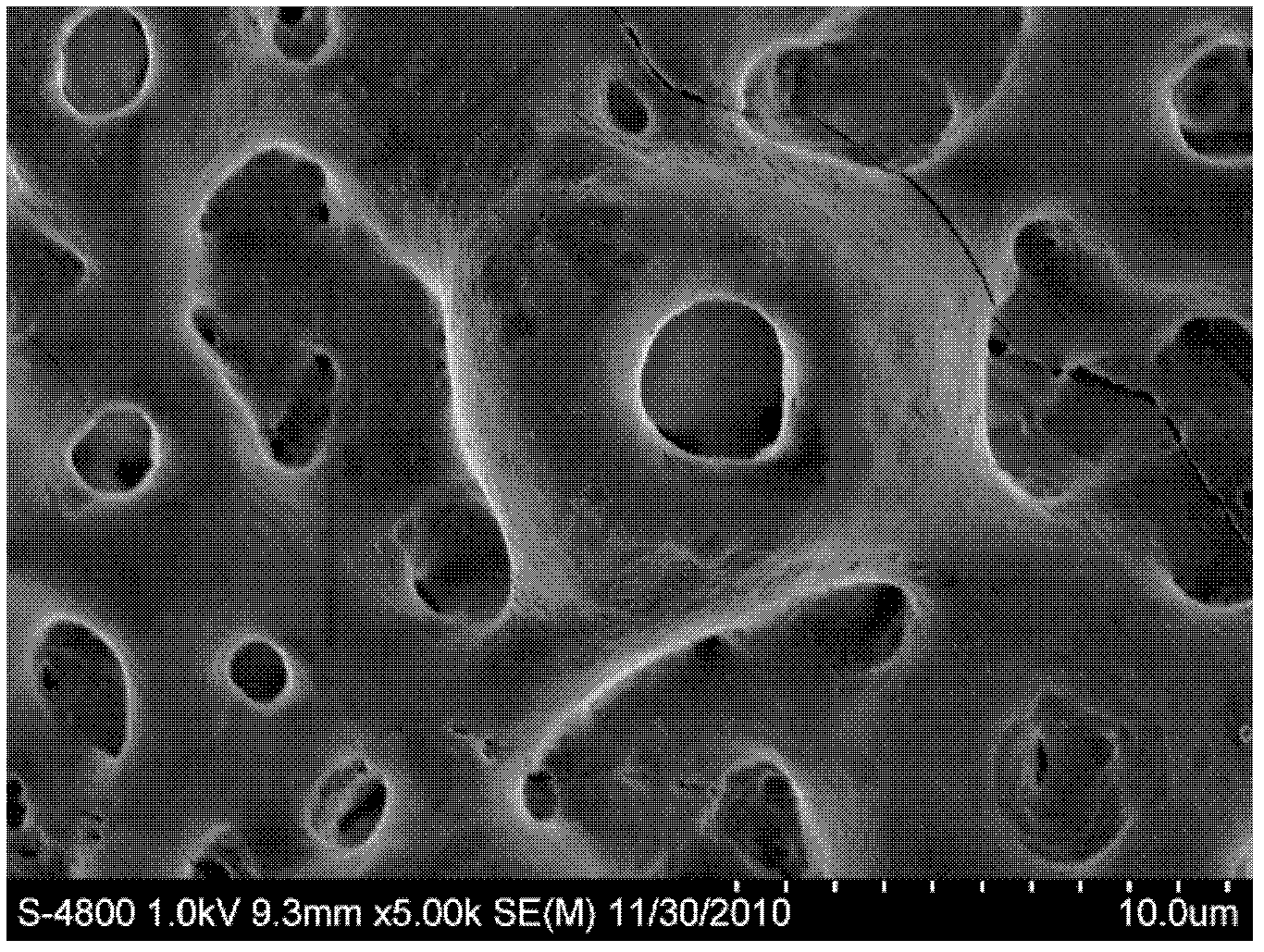

[0037] 3) The micro-arc oxidation coating with micro-nano morphology was prepared on the outer surface of the implant substrate by the micro-arc oxidation process: the stainless steel tank was used as the cathode, and the dental implant substrate was used as the anode, which was placed in the electrolyte prepared in the previous step. The process parameters are: power frequency 100Hz, voltage 400V, duty cycle 20%, processing time 5min, reaction temperature is room temperature;

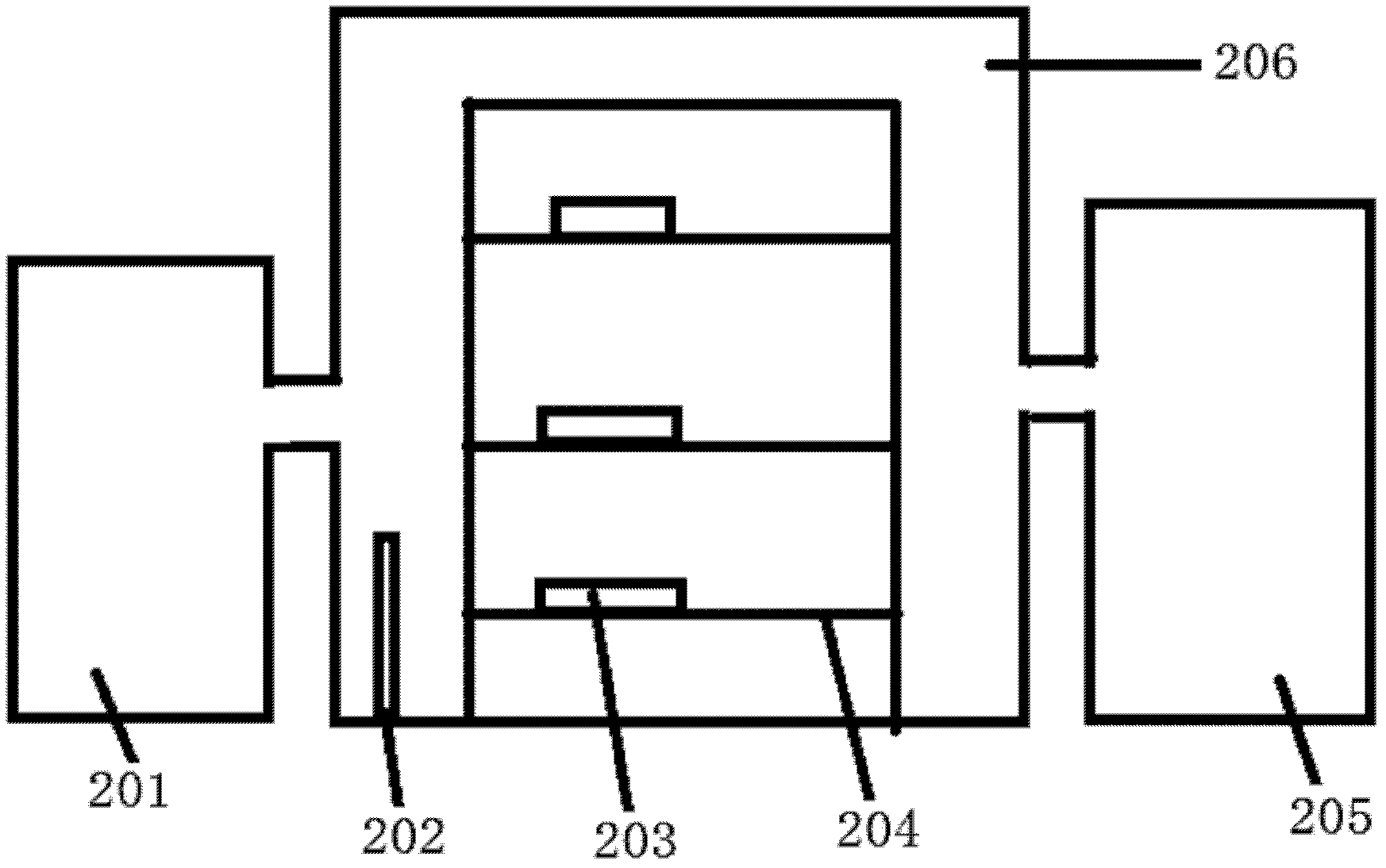

[0038] 4) After the preparation of the titanium ...

Embodiment 2

[0042] 1) Select pure titanium to process it into a dental implant matrix. After the surface of the dental implant matrix is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes, and then dried for use;

[0043] 2) Configure the electrolyte solution for the micro-arc oxidation process: deionized water is used as the solvent, and the solute is 0.04M β-sodium glycerophosphate and 0.2M calcium acetate;

[0044] 3) The micro-arc oxidation coating with micro-nano morphology was prepared on the outer surface of the implant substrate by the micro-arc oxidation process: the stainless steel tank was used as the cathode, and the dental implant substrate was used as the anode, which was placed in the electrolyte prepared in the previous step. The process parameters are: power frequency 100Hz, voltage 400V, duty cycle 20%, processing time 4min, and reaction temperature at room temperature;

[0045] 4) After the preparation of the titan...

Embodiment 3

[0049] 1) Select pure titanium to process it into a dental implant matrix. After the surface of the dental implant matrix is polished, it is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 30 minutes, and then dried for use;

[0050] 2) Configure the electrolyte solution for the micro-arc oxidation process: deionized water is used as the solvent, and the solute is 0.04M β-sodium glycerophosphate and 0.2M calcium acetate;

[0051] 3) The micro-arc oxidation coating with micro-nano morphology was prepared on the outer surface of the implant substrate by the micro-arc oxidation process: the stainless steel tank was used as the cathode, and the dental implant substrate was used as the anode, which was placed in the electrolyte prepared in the previous step. The process parameters are: power frequency 100Hz, voltage 400V, duty cycle 20%, processing time 6min, and reaction temperature at room temperature;

[0052] 4) After the preparation of the titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com