Electrostatic precipitation filter with integrated structure and polarization process for electrostatic precipitation filter

An electrostatic dust collection and filter technology, which is applied to electrostatic dust collection filters, high-efficiency demand occasions, and low wind resistance fields. It can solve problems such as electric shocks in exposed contact areas, complex safety circuits, and complex high-voltage power supplies. Charge storage time, improve dust collection effect, enhance the effect of electret effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

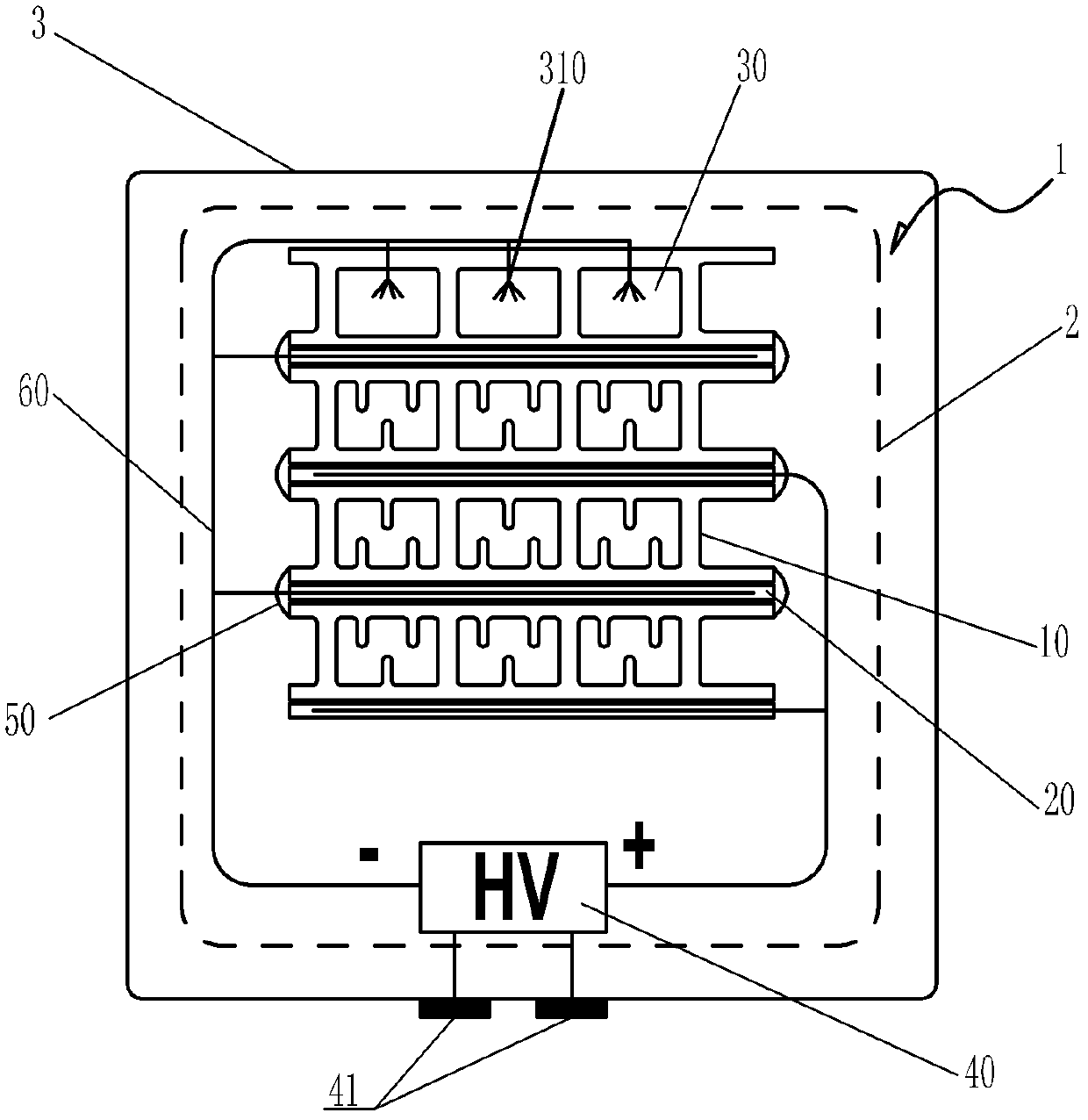

[0065] The present invention is an electrostatic dust collection filter for electrostatic dust collection type air purification equipment, see figure 1 As shown, the filter includes: a main body 1 as a dust collection device and an outer frame 3 for encapsulating the main body 1, wherein the main body 1 is composed of multi-layer stacked orifice plates 10 and an airtight conductive film 20 between the orifice plates 10 constitute.

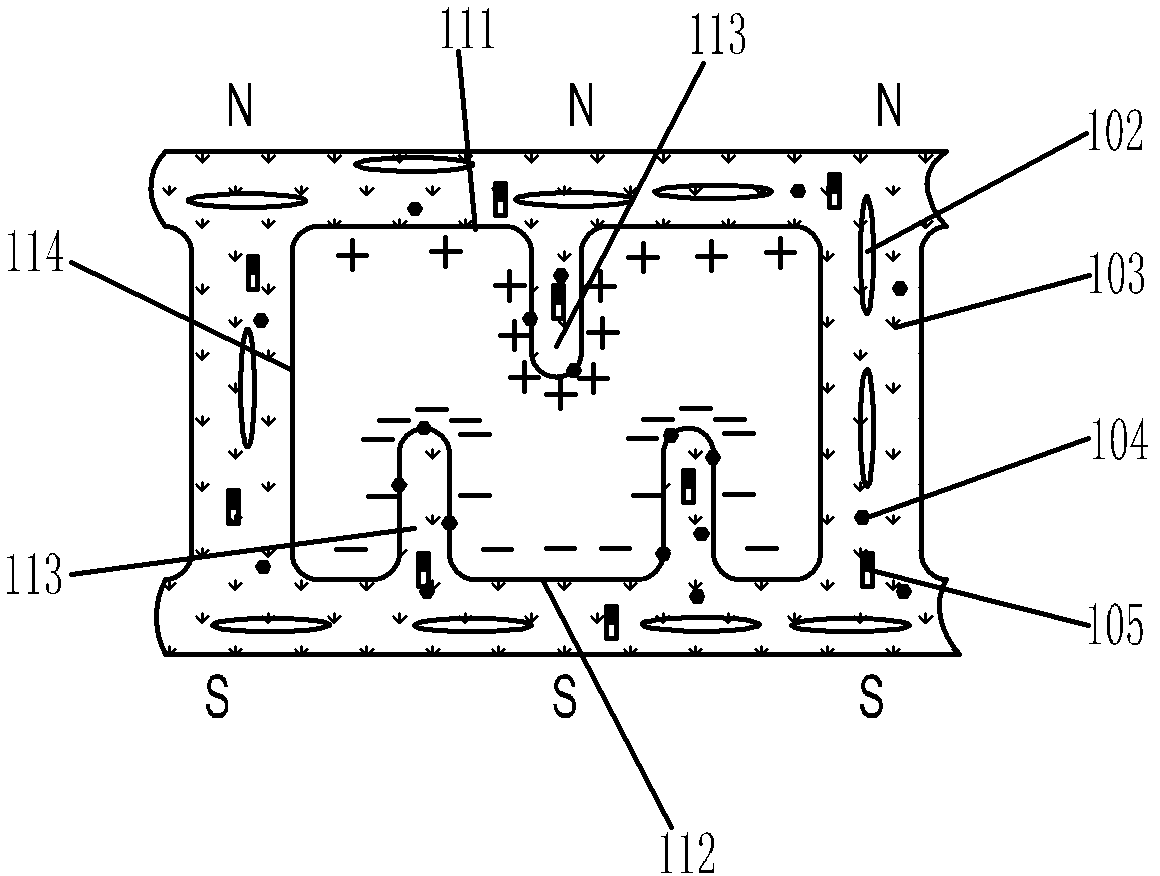

[0066] The orifice plate 10 can be made of PP (polypropylene), PE (polyethylene), PC (polycarbonate), PVC (polyvinyl chloride), PVDF (polyvinylidene fluoride), PTFE (polytetrafluoroethylene), etc. Injection molding of materials with electret properties. At the same time, plastic micro-foaming materials such as electret materials, negative ion generating materials and magnetic materials can be added therein. combine figure 2 The orifice plate 10 is integrally formed with an array of linear holes 110 for gas to pass through. In this embodiment, a...

Embodiment 2

[0104] The difference from Embodiment 1 is that in-line electret polarization is performed during the injection molding process of the orifice plate 10 .

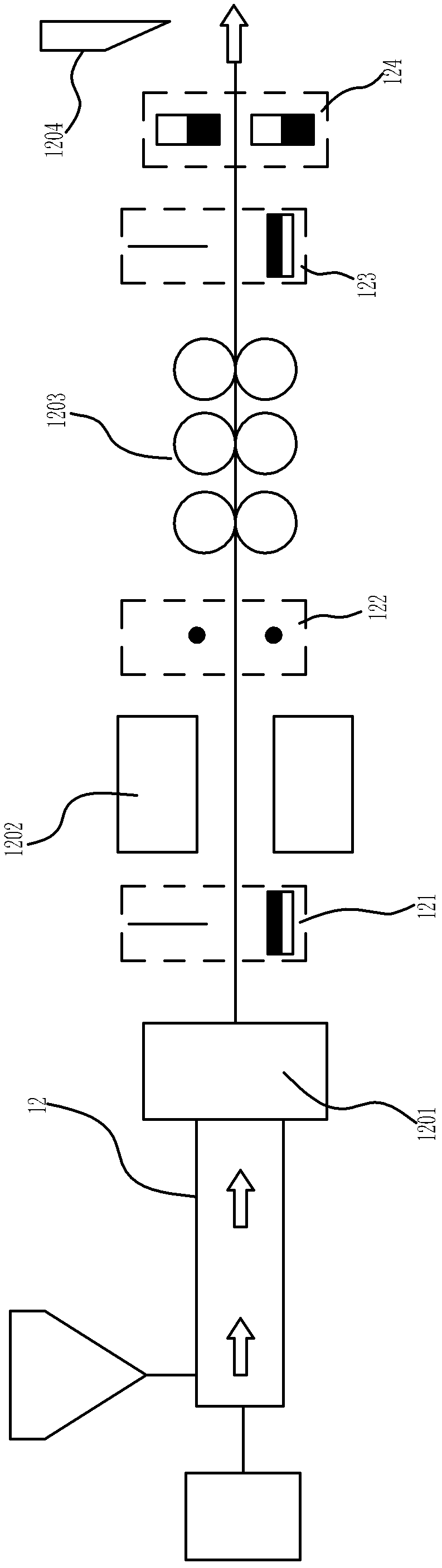

[0105] see image 3 As shown, the orifice plate 10 is formed by one-time injection molding of an injection molding machine, and the electret and magnetization of materials are carried out to the orifice plate 10 during the injection molding process. The process includes:

[0106] a. Perform positive corona or negative corona primary electret 121 at the exit 1201 of the injection mold 12 and the entrance space of the cooling section 1202. The use includes: needle plate, thread plate, thread, needle-dielectric barrier plate, line-dielectric barrier version, the electret voltage difference is 10-50Kv;

[0107] b. Between the cooling section 1202 and the traction section 1203, a corona secondary electret 122 with a needle plate, wire plate, and wire electrode structure but opposite to the polarity in step a is used, and the el...

Embodiment 3

[0117] The difference between this embodiment and Embodiment 1 is that the orifice plate 10 adopts a foaming process.

[0118] See figure 2 As shown, the material used in the orifice plate 10 is added with: a microcellular foaming agent with nitrogen as the microfoaming gas, the foaming ratio is 0.1 to 10%, and the lens-shaped or spindle-shaped microcellular foam is formed under the action of injection molding stretching. Bubbles 102. In Example 3, a well-known technology in the injection molding industry was adopted, and 0.2% of azo-based microfoaming agent was mixed into the PP raw material for foam injection molding. The formed orifice plate 10 has a foaming volume of 5% and a diameter of 5-20um. The foam body forms ellipsoidal or lens-shaped microbubbles 102 under the action of stretching, and the thickness of the orifice plate 10 is about 3.1mm.

[0119] In this embodiment, on the basis of Embodiment 1, microbubbles are distributed in the plastic material of the orific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com