Method and device for treating high-concentration organic wastewater and producing methane gas

A technology of organic wastewater and methane gas, applied in organic chemistry, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of unutilized organic substances, bacterial poisoning, and susceptibility to water quality fluctuations, etc., to achieve Realize resource utilization and reduce overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

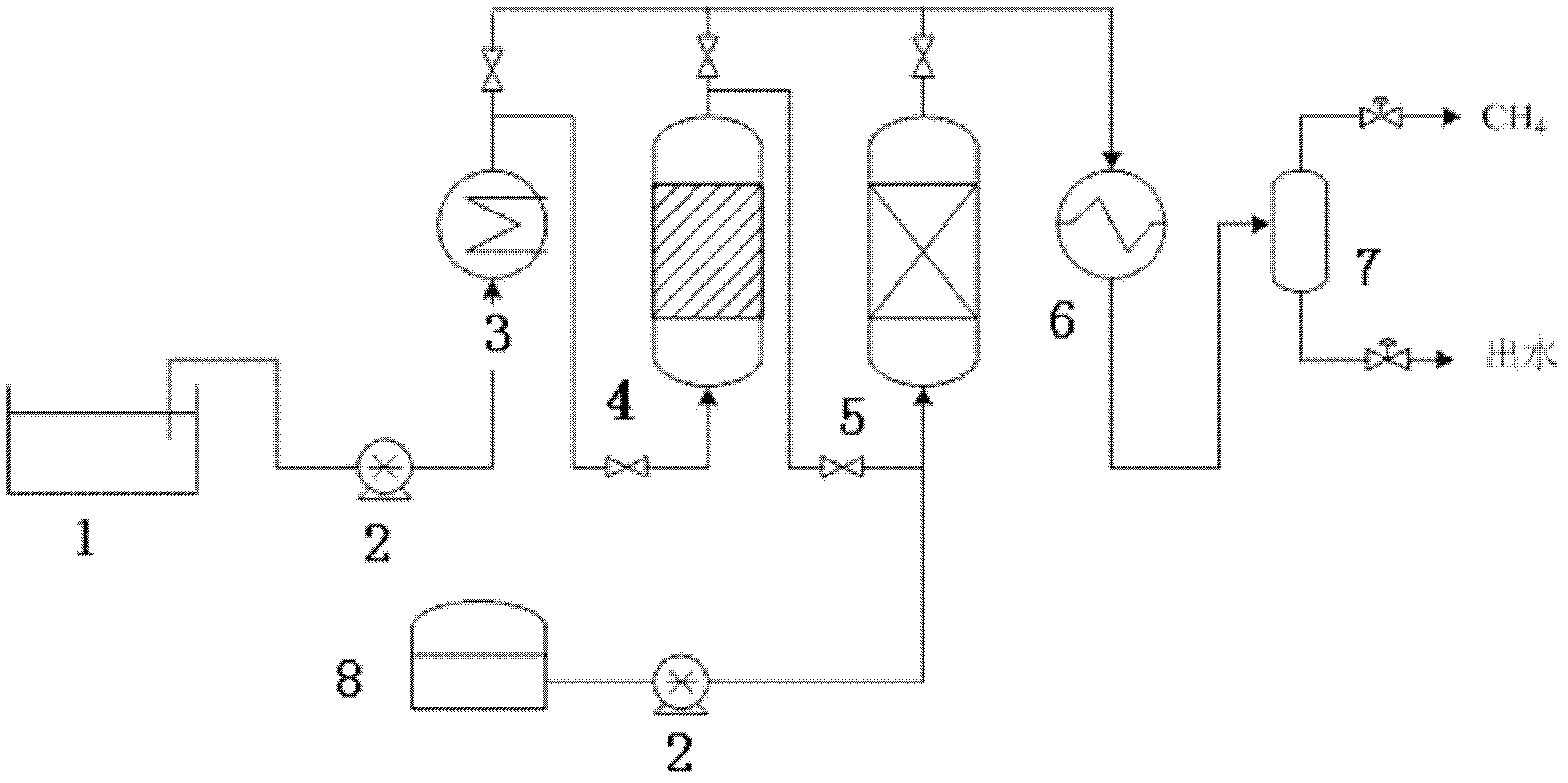

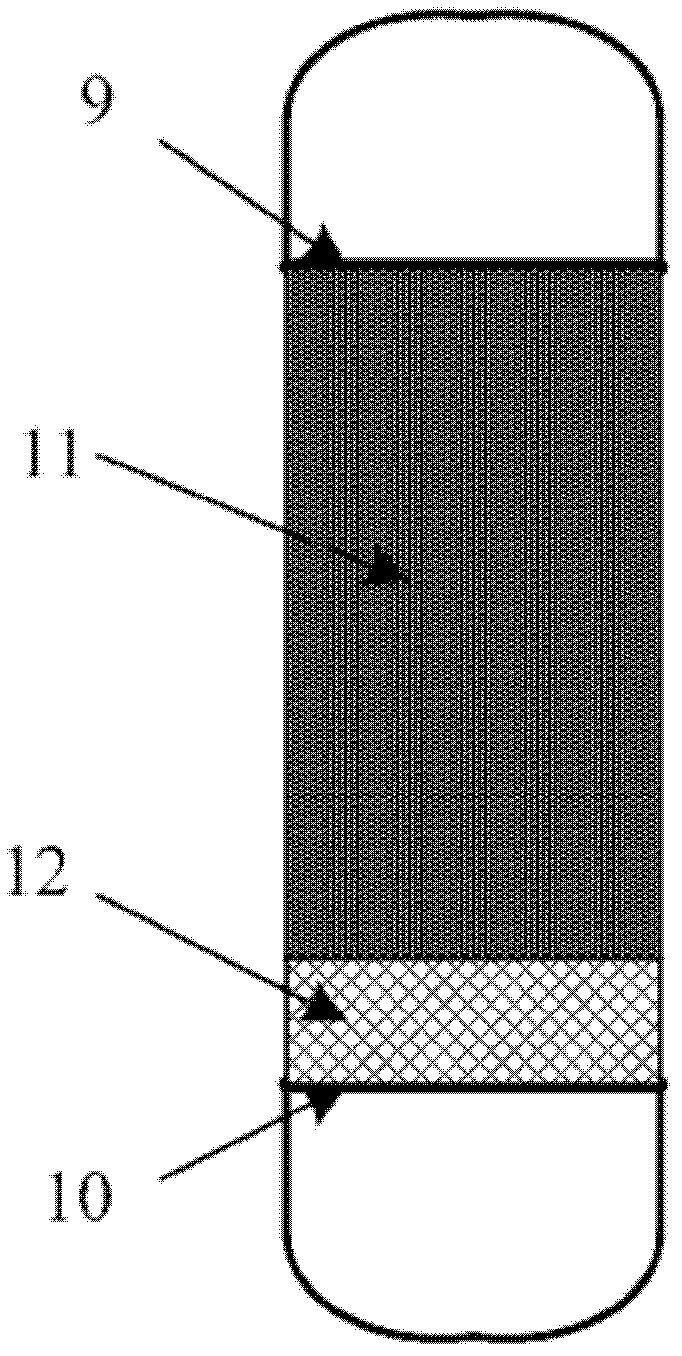

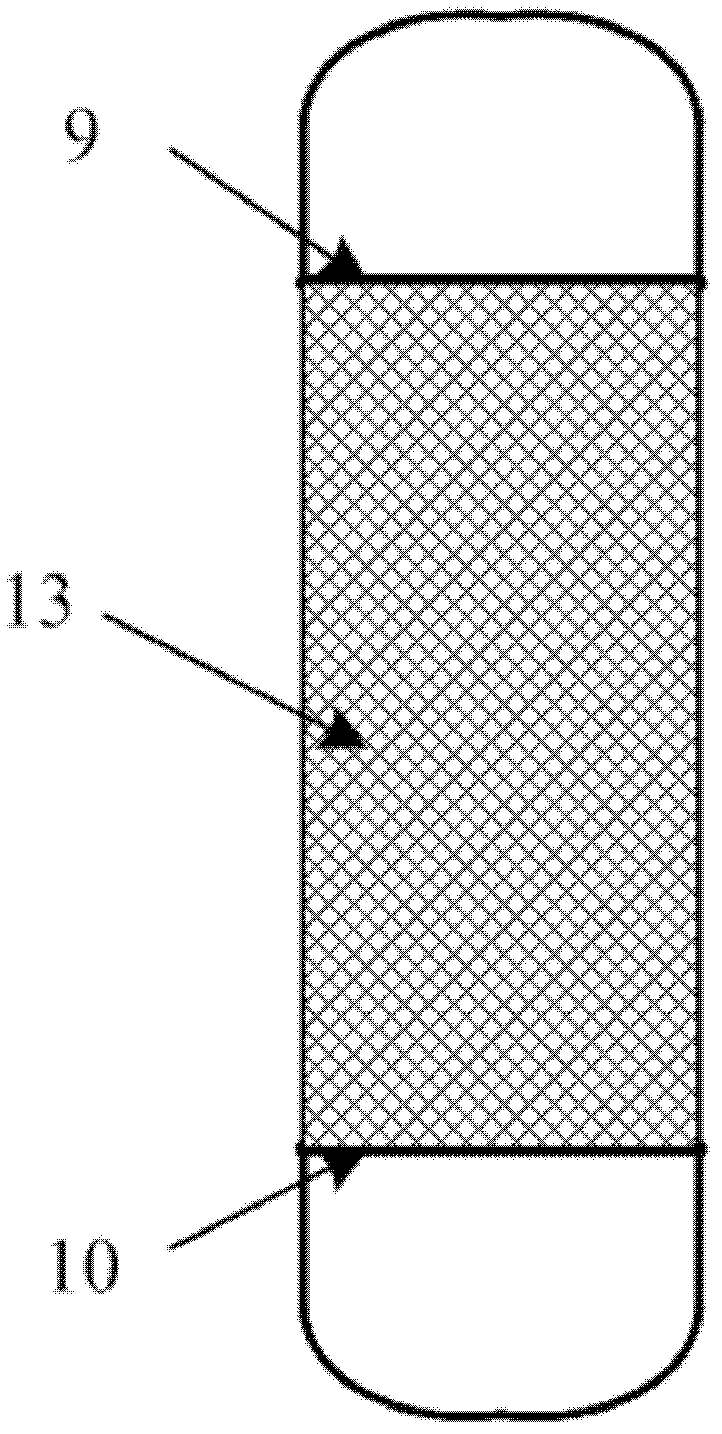

[0051] process such as figure 1 Shown, the internal diameter of catalytic reaction tower 4 that the present invention adopts is 110mm, and height is 1200mm, and material is stainless steel, and the inside is lined with titanium material; 6.5L; the carrier is spherical TiO 2 Particles, the particle size is 10-15mm, the catalyst is spherical TiO coated with precious metal Ru 2 The particle size is 5-7 mm, and the coating concentration of Ru is 5%. The specifications and materials of the carbon dioxide absorbing tower 5 are the same as those of the catalytic reaction tower 4, and the inside is filled with 8L of ceramic packing, which is spherical in shape overall and has a particle diameter of 10 mm. Feed pump 2 is a reciprocating piston pump (Wuxi Linjie High Pressure Pump Factory, w3020), with a power of 20kw; heater 3 is an electric heating furnace (Suyi HVAC Equipment Co., Ltd.), with a total power of 15kw; condenser 6 It is a casing condenser, the condensed water goes thr...

Embodiment 2

[0054] The device in Example 1 was used to treat methanol-containing organic industrial wastewater discharged from a methanol plant in an oil field. The wastewater contains 4% to 5% (mass fraction) of methanol, COD cr About 1000mg / L, the pH value is between 6.7 and 7.2. Continuously feed the waste water into the device, control the influent flow rate to 20L / h; the lye flow rate to 2L / h; control the operating temperature to 280°C and the operating pressure to 90kg / cm 2 During the experiment, the effluent and gas samples at the outlet of the gas-liquid separator were collected for analysis. The results show that the TOC concentration of the effluent is about 80mg / L, and the COD cr The concentration is about 200mg / L. The gas flow at the gas outlet of the separator fluctuates around 550NL / h, where CH 4 Concentration is about 82%, CO 2 Concentration is about 8%, H 2 Concentration is about 2%, C 2 h 6 About 5%.

Embodiment 3

[0056] Treatment of alkali slag wastewater from an oil refinery, the initial CODcr concentration of wastewater is 20000mg / l. In the above process flow, two catalytic reaction towers 4 with the same specifications are connected in series, the water flow rate is controlled to be 20L / h, and the lye flow rate is 2L / h; the operating temperature is 280°C, and the operating pressure is 90kg / cm 2 . The analysis results show that the concentration of CODcr in the effluent is only 670mg / L, and the gas flow at the gas outlet of the upper part of the gas-liquid separator 7 fluctuates around 9000NL / h, of which CH 4 Concentration is 88%, CO 2 Concentration is about 8%, H 2 Concentration is about 2%, C 2 h 6 About 2%. It can be seen that after the catalytic reaction, most of the organic matter in the simulated wastewater was converted into methane gas, and a good treatment effect was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com