Phosphorous-removing lytag as well as preparation method and application thereof

A technology for fly ash ceramsite and fly ash, which can be used in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of limited improvement of removal effect, reduce the use of natural minerals, reduce operation and maintenance costs, Small secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

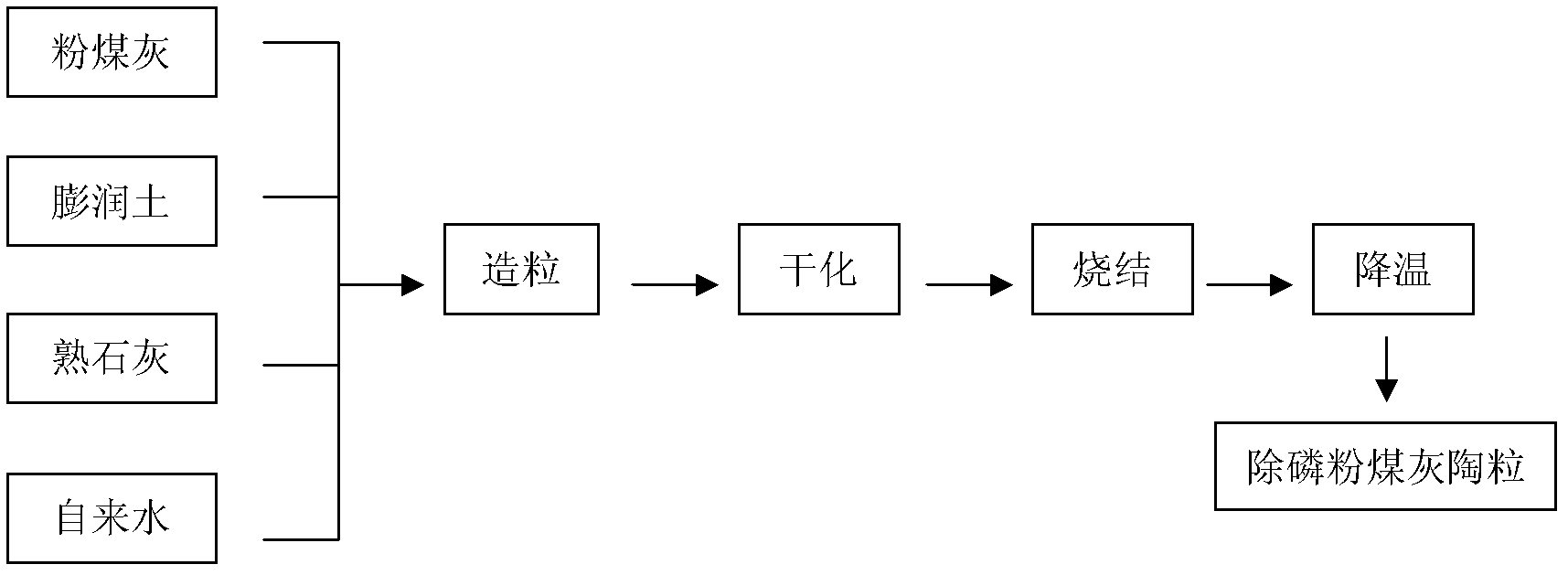

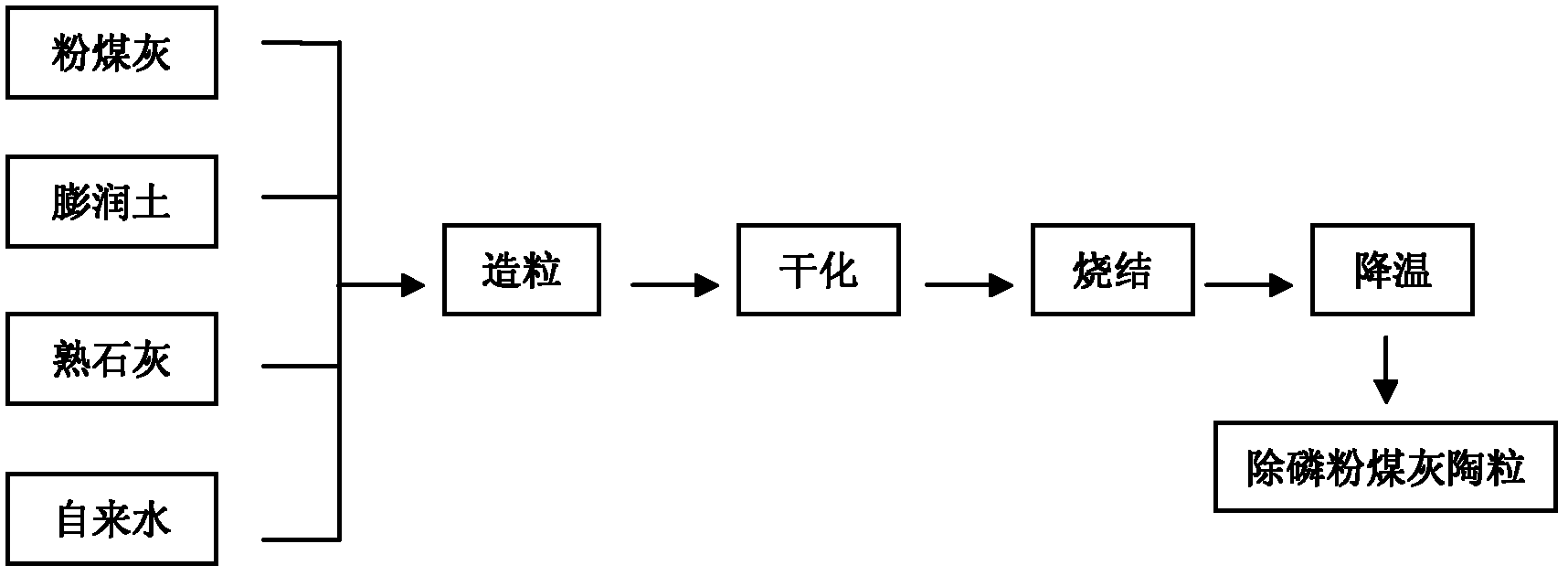

[0024] Example 1: figure 1 It is a flow chart of the preparation steps of phosphorus removal fly ash ceramsite, and the specific process of preparing phosphorus removal fly ash ceramsite according to this process is as follows:

[0025] (1) Mixing: according to the fineness of 200 mesh fly ash (Nanhai Power Plant, Foshan City, Guangdong Province) is 50%, bentonite (provided by Guangzhou Xinxin Chemical Operation Department) is 35%, slaked lime is 10%, and tap water is 5%. Proportion by mass percentage After weighing the raw materials respectively, mix and stir evenly to obtain the mixed raw materials.

[0026] (2) Granulation: Add the mixed raw materials into the disc granulator (Pingxiang Jinfeng Industrial Co., Ltd.) in stages. The rotating speed of the disc granulator is 30rpm during granulation. Use a sprayer to spray atomized tap water (50ml each time) and granulate, and then add material and water for the next time after an interval of 5-10 minutes until the granulation...

Embodiment 2

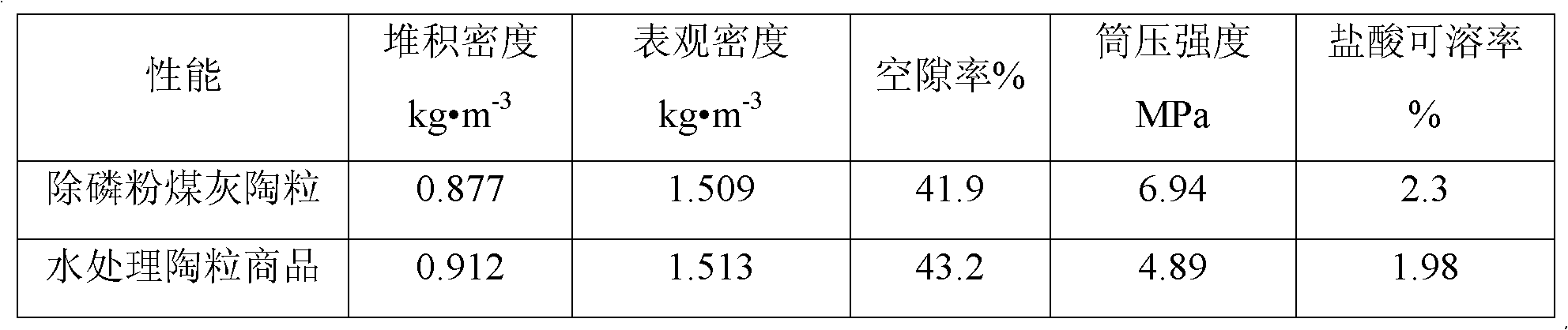

[0032] Example 2: Phosphorus removal effect when fly ash ceramsite is used as phosphate remover

[0033] With the phosphorus-removing fly ash ceramsite and water treatment ceramsite commodity (with the water treatment ceramsite commodity in embodiment 1, the same below) prepared by embodiment 1, carry out phosphate depletion respectively in self-prepared rich phosphate waste water Remove experiments. The experimental process is as follows:

[0034]Dissolve potassium dihydrogen phosphate in deionized water to prepare a stock solution with a concentration of 50mg / L. Take a certain amount and dilute it to 10mg / L for use in the experiment. Take 50mL and pour it into a 100mL Erlenmeyer flask. The pH is the natural value (about 7.0) , Weigh 1.00g of phosphorus removal fly ash ceramsite or water treatment ceramsite, put it into the bottle, plug the lid tightly and put it into a constant temperature oscillator. Set the oscillation conditions as follows: temperature 25°C, oscillation ...

Embodiment 3

[0036] Example 3: Experimental research on using the phosphorus removal fly ash ceramsite prepared in Example 1 to strengthen phosphorus removal in constructed wetlands

[0037] Construction of constructed wetlands for phosphorus removal Experimental research on the use of fly ash ceramsite to strengthen phosphorus removal in constructed wetlands. Constructed wetland is a vertical flow crushed stone bed constructed wetland. The purpose is to carry out advanced treatment of the effluent discharge water quality after secondary treatment, and improve the effluent water quality to the first-level A standard, that is, the total phosphorus concentration is 0.5mg / L, and the ammonia nitrogen concentration is 0.5mg / L. 5mg / L or less.

[0038] The overall dimension of the constructed wetland is: 2700×1000×700 (mm). Separate it with a waterproof partition (PVC board, the thickness can be ignored), and divide it into two grids. The size of each grid is: 2700×500×700 (mm), and the water di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cylinder compressive strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com