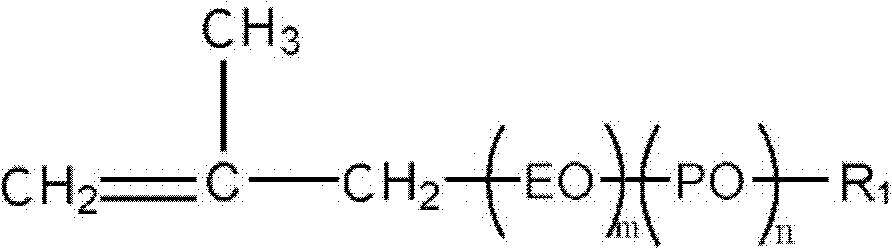

Isobutylene polyether polycarboxylic water reducer and preparation method thereof

An isobutylene-based polyether and polycarboxylic acid-based technology, applied in the field of concrete admixtures, can solve the problems affecting the cost performance and market competitiveness of water reducers, the high price of isopentenol, and narrow source channels, etc., to achieve high cost performance, The effect of slump-proof cement adaptability and high cement adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Monomer A is isobutenyl polyoxyethylene polyoxypropylene ether, molecular weight is 2400; Monomer B is acrylic acid; Initiator D is "H 2 o 2 -VC" redox system, the chain transfer agent E is thioglycolic acid.

[0031] Dissolve 16.08kg of monomer B and 1.62kg of chain transfer agent E in 40kg of distilled water as solution 1#. Dissolve 0.81kg VC (ascorbic acid) in 40kg distilled water as solution 2#. Add 124.20kg of monomer A, 3.02kg of H into the reactor 2 o 2 Mix with 131kg of distilled water, stir to dissolve, then raise the temperature to 62±2°C, start to add solution 1# and solution 2# dropwise at the same time, the dropping time of solution 1# and 2# is 3.5h and 4h, and continue to react for 1h after the dropwise addition is completed . After the reactants are cooled, adjust the pH to 6-8 with 40% sodium hydroxide solution to obtain polycarboxylate water reducer PC-1 with a solid content of 40%.

Embodiment 2

[0032] Example 2: Monomer A is isobutylene polyoxyethylene polyoxypropylene ether with a molecular weight of 2400; Monomer B is acrylic acid; Monomer C is sodium methacrylic sulfonate; Initiator D is ammonium persulfate.

[0033] Dissolve 15.6kg of monomer B in 18.5kg of distilled water as solution 1#. Dissolve 1.25kg of ammonium persulfate in 22.1kg of distilled water as solution 2#. Add 136.2kg of monomer A, 2.55kg of sodium methacrylate and 149.4kg of distilled water into the reaction kettle, stir to dissolve, then raise the temperature to 64±2°C, and start adding solution 1# and solution 2# dropwise at the same time, solution 1# The dropwise addition time of and 2# is 3.0h and 3.5h, and the reaction is continued for 2.5h after the dropwise addition is completed. After the reactant is cooled, adjust the pH to 6-8 with 45% sodium hydroxide solution to obtain the polycarboxylate water reducer PC-2 with a solid content of 45%.

Embodiment 3

[0034] Example 3: Monomer A is isobutylene polyoxyethylene polyoxypropylene ether with a molecular weight of 2400; monomer B is acrylic acid; initiator D is ammonium persulfate, and chain transfer agent E is mercaptopropionic acid.

[0035]Dissolve 12.4kg of monomer B and 0.75kg of chain transfer agent E in 40.6kg of distilled water as solution 1#. Dissolve 1.2kg of ammonium persulfate in 43.9kg of distilled water as solution 2#. Add 82.7kg of monomer A and 140.2kg of distilled water into the reaction kettle, stir to dissolve, then raise the temperature to 62±2°C, start to drop solution 1# and solution 2# at the same time, the dropping time of solution 1# and 2# is 2.5 h and 3.0h, continue to react for 2.0h after the dropwise addition. After the reactant is cooled, adjust the pH to 6-8 with 30% sodium hydroxide solution to obtain the polycarboxylate water reducer PC-3 with a solid content of 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com