Method for recovering vanadium and chromium from vanadium and chromium-containing slag

A vanadium-chromium slag, vanadium-chromium technology, applied in the direction of improving process efficiency, can solve the problems of high energy consumption required for evaporation and concentration of circulating media, unrecycled chromium, loss of valuable elements, etc. Effects of medium purification, high vanadium and chromium extraction efficiency, and improved flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

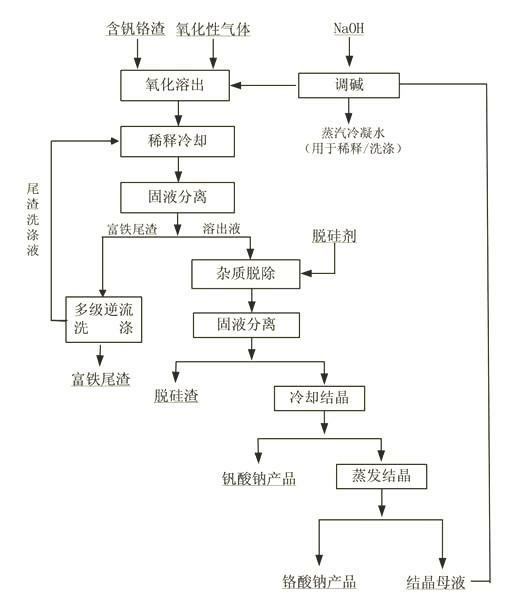

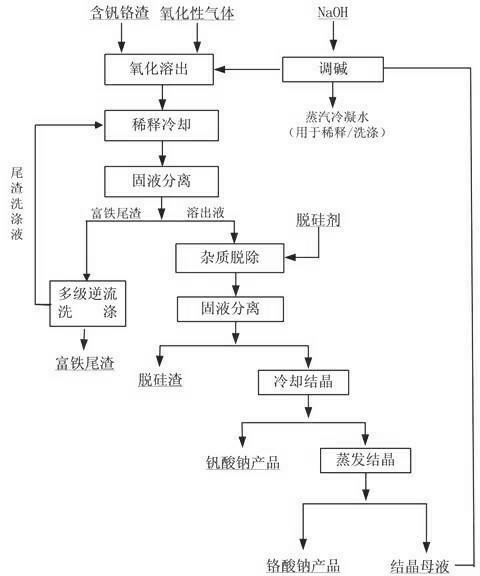

[0029] Example 1: figure 1 As shown, the method for reclaiming vanadium-chromium from vanadium-chromium-containing slag adopts the following process steps.

[0030] (1) Ingredients: In the autoclave, add the secondary slag (the primary water leaching slag after the vanadium slag is roasted by sodium hydroxide) and 30wt% NaOH solution, wherein the secondary slag contains V 2 o 5 2.3wt%, Cr 2 o 3 4.41wt%, sodium hydroxide solution: vanadium-containing chromium slag=4:1 (quality);

[0031] (2) Reaction (ie figure 1 Oxidative dissolution in the process): heat the material prepared in step (1) to 250°C, then pass oxygen into it, and stir to make the secondary slag fully contact with oxygen, control the total pressure of the system to 3MPa, and keep the temperature for 3h. Get NaOH, Na 3 VO 4 、Na 2 CrO 4 、Na 2 SiO 4 and other solutions and reaction slurry of iron-rich tailings;

[0032](3) Dilution: Add a diluent to the reaction slurry to dilute to a NaOH concentration...

Embodiment 2

[0038] Embodiment 2: The method for recovering vanadium-chromium from vanadium-chromium-containing slag adopts the following process steps.

[0039] (1) Ingredients: In the autoclave, add the vanadium slag roasting clinker and 20wt% NaOH solution, wherein the vanadium slag contains V 2 o 5 11.3wt%, Cr 2 o 3 3.61wt%, sodium hydroxide solution: vanadium-containing chromium slag=6:1 (quality);

[0040] (2) Reaction: Heat the material prepared in step (1) to 280°C, then introduce air into it, and stir to make the roasted clinker containing vanadium slag fully contact with air. The total pressure of the control system is 4MPa, and the heat preservation reaction is 5h , to obtain a reaction slurry;

[0041] (3) Dilution: adding water to the reaction slurry to dilute to a NaOH concentration of 220g / L to obtain a mixed slurry;

[0042] (4) Filtration and separation: the mixed slurry is filtered and separated at 100°C to obtain iron-rich tailings and eluate;

[0043] (5) Elimin...

Embodiment 3

[0047] Embodiment 3: The method for recovering vanadium-chromium from vanadium-chromium-containing slag adopts the following process steps.

[0048] (1) Ingredients: In the autoclave, add vanadium extraction tailings and 40wt% NaOH solution, wherein the vanadium slag contains V 2 o 5 1.3wt%, Cr 2 o 3 3.51wt%, sodium hydroxide solution: vanadium-containing chromium slag=5:1 (quality);

[0049] (2) Reaction: Heat the material prepared in step (1) to 300°C, then pass oxygen-enriched air into it, and stir to make the roasted clinker containing vanadium slag fully contact with oxygen-enriched air, and the total pressure of the control system is 2MPa , heat preservation reaction 1h, obtain reaction slurry;

[0050] (3) Dilution: adding water to the reaction slurry to dilute to a NaOH concentration of 300g / L to obtain a mixed slurry;

[0051] (4) Filtration and separation: the mixed slurry is filtered and separated at 130°C to obtain iron-rich tailings and eluate;

[0052] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com