Diaphragm for high thermal safety temperature lithium ion cell and preparation method thereof

A lithium-ion battery, safe temperature technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of safety performance to be improved, inability to effectively thermally close holes, loss of protection functions, etc., to achieve good physical structure support, The effect of improving electrophilic performance and preventing battery explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve PVDF-HFP (KYNAR FLEX 2801) in a mixed solvent of N-N dimethylformamide and acetone (volume ratio 4:3), and add DBP (dibutyl phthalate into Pore agent), prepared into a polymer solution with a solid content of 5wt%, and stirred at 35°C for 1.5h to form a homogeneous casting solution. A porous polytetrafluoroethylene substrate with a thickness of 2 μm, a mechanical strength (machine direction) of 60 MPa, an average pore diameter of 5 μm, and a porosity of 80% was immersed in the casting solution for 0.5 h at 35° C. 10 -1 Torr, dried at 80° C. for 12 h to remove the solvent. Take out the initial composite membrane and soak it in absolute ethanol at 40°C to extract the pore-forming agent. Naturally drying to remove ethanol produces a separator for lithium-ion batteries with a high thermal safety temperature. The thermal closure temperature of the separator is 125°C, and the thermal safety temperature can reach 338°C.

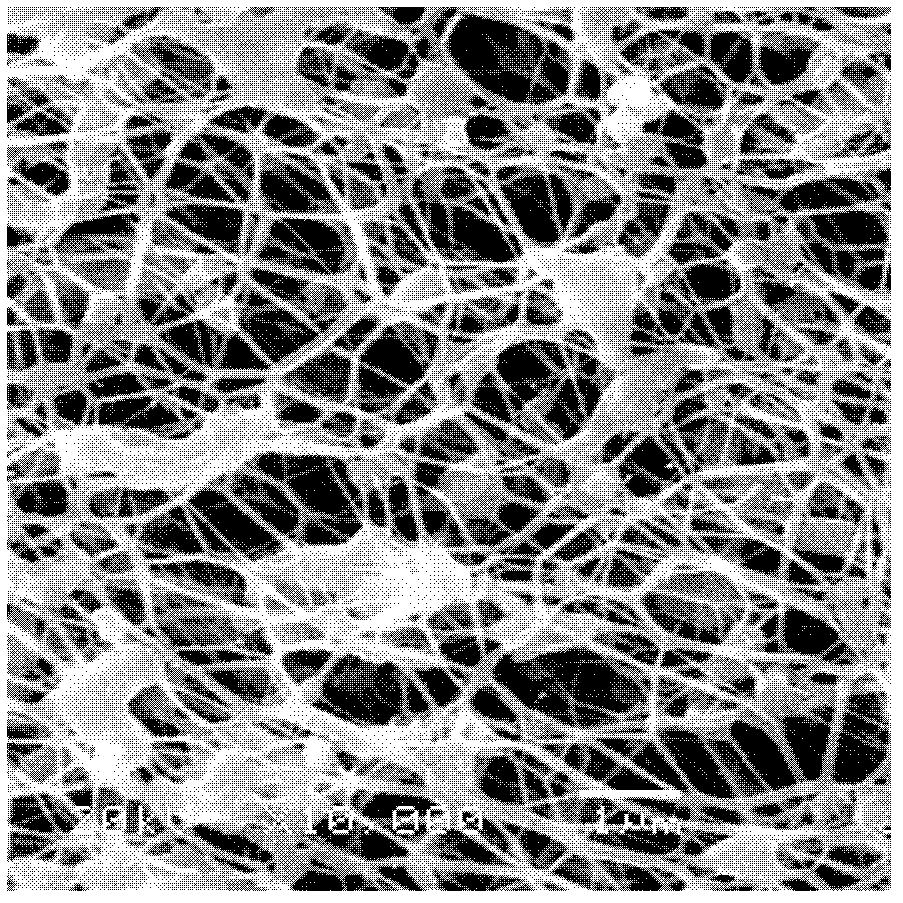

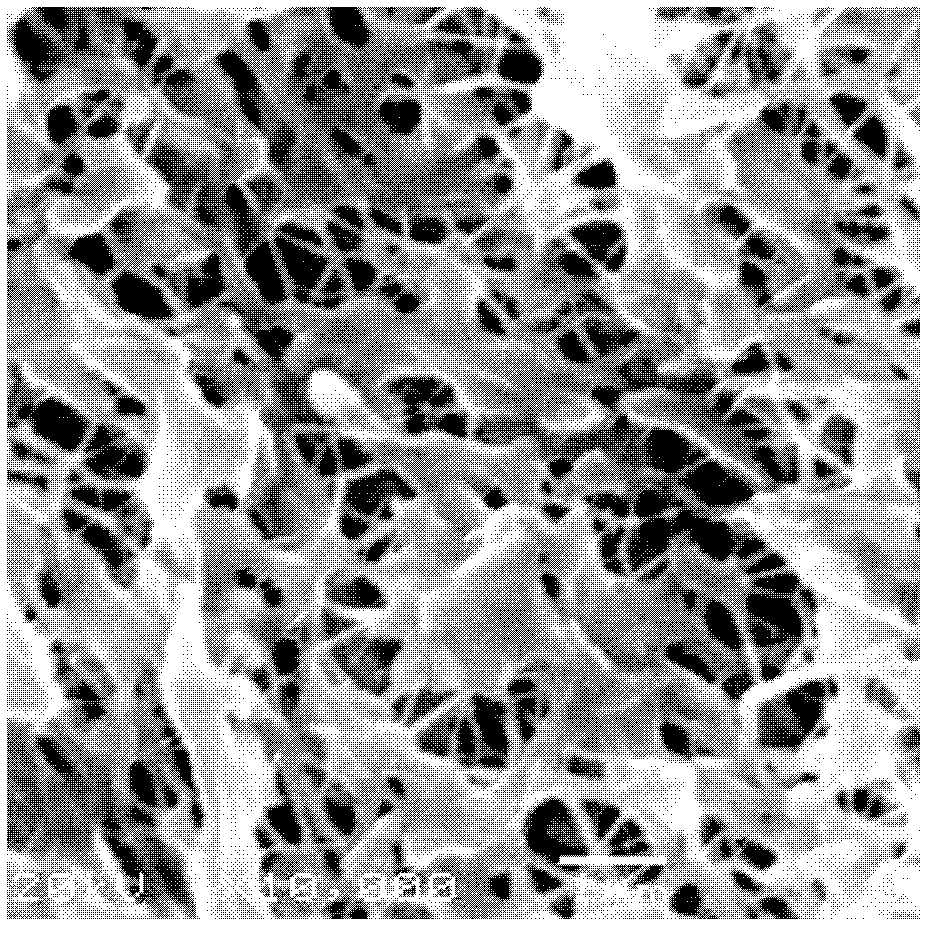

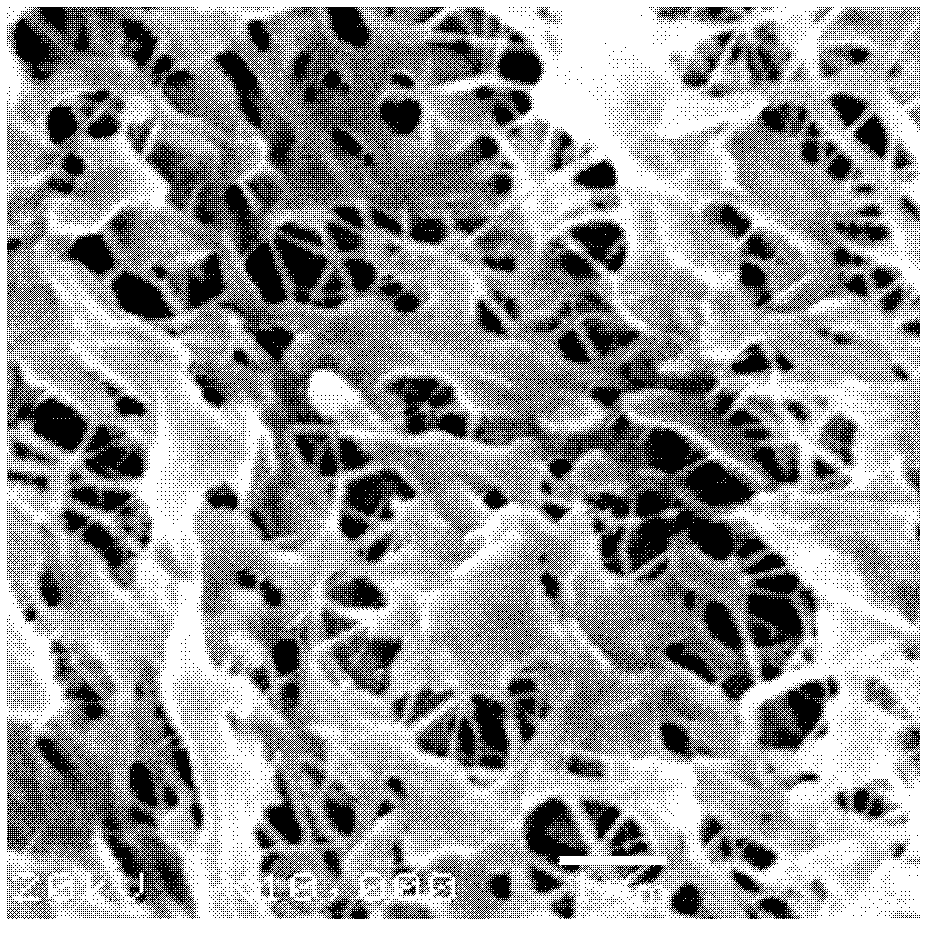

[0030] The scanning electron microscope p...

Embodiment 2

[0032] PVDF-HFP (Aldrich, M w=400,000) was dissolved in the mixed solvent of N-methylpyrrolidone and acetone (volume ratio 2:1), and DBP and 0.1g P123 (polyoxypropylene-polyoxyethylene copolymer, EO / PO / EO=30 / 70 / 30, M w ==5800), prepare a polymer solution with a solid content of 8wt%, and stir at 40°C for 1.5h to form a homogeneous casting solution. A porous polytetrafluoroethylene substrate with a thickness of 5 μm, a mechanical strength (machine direction) of 150 MPa, an average pore diameter of 4 μm, and a porosity of 75% was immersed in the casting solution for 1 hour at 40° C. -1 Torr, dried at 80° C. for 12 h to remove the solvent. The initial composite membrane was taken out and soaked in absolute ethanol at 70°C for 6 hours to extract the pore-forming agent. Drying and removing ethanol produces a separator for lithium-ion batteries with a high thermal safety temperature. The thermal closure temperature of the separator is 133° C., and the thermal safety temperature ...

Embodiment 3

[0033] Example 3 Material

[0034] High-density polyethylene (Samsung general chemical, M w =2400,000) was dissolved in N-N dimethylacetamide and acetone (volume ratio 4: 1) mixed solvent, added liquid paraffin equivalent to 5wt.% of organic solvent quality, prepared a polymer solution with a solid content of 10%, at 40 Stir at ℃ for 1.5h to form a homogeneous casting solution. A porous polytetrafluoroethylene matrix with a thickness of 5 μm, a mechanical strength (machine direction) of 80 Pa, an average pore diameter of 4 μm, a porosity of 50% and a porosity of 75% was immersed in the casting solution at 40°C. 1h to fully immerse the casting solution, after taking it out in 10 -1 Torr, dried at 100° C. for 12 h to remove the solvent. Take out the initial composite membrane, extract the pore-forming agent with acetone, dry and remove the acetone to prepare a separator for lithium-ion batteries with a high thermal safety temperature. The thermal closure temperature of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com