Preparation method of zinc oxide microsphere with nanoflower-shaped microstructure

A microstructure, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of difficult engineering scale-up, complicated process, slow preparation, etc., and achieve convenient industrial production, mild reaction environment, and post-treatment. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

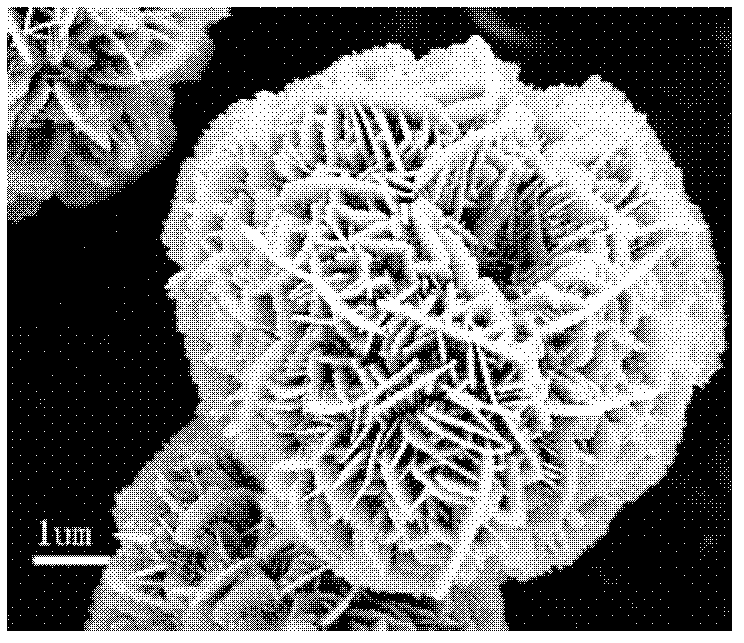

[0023] At room temperature, dissolve 1 g of boric acid in 20 mL of deionized water, prepare 15 mL of zinc acetate aqueous solution with a zinc ion molar concentration of 0.5 mol / L, and 10 mL of a sodium hydroxide solution with a molar concentration of 5 mol / L, and then stir with a glass rod to slowly 15mL of zinc salt solution is poured into sodium hydroxide solution, and a clear aqueous solution will be obtained. Then, 20 mL of boric acid solution was quickly poured into the obtained clear solution, and a white precipitate was obtained after standing still. Centrifuge the precipitate, put it in an oven at 80°C, and dry it for 4 hours to obtain zinc oxide microspheres constructed of nanosheets. The SEM image is as follows: figure 1 shown.

Embodiment 2

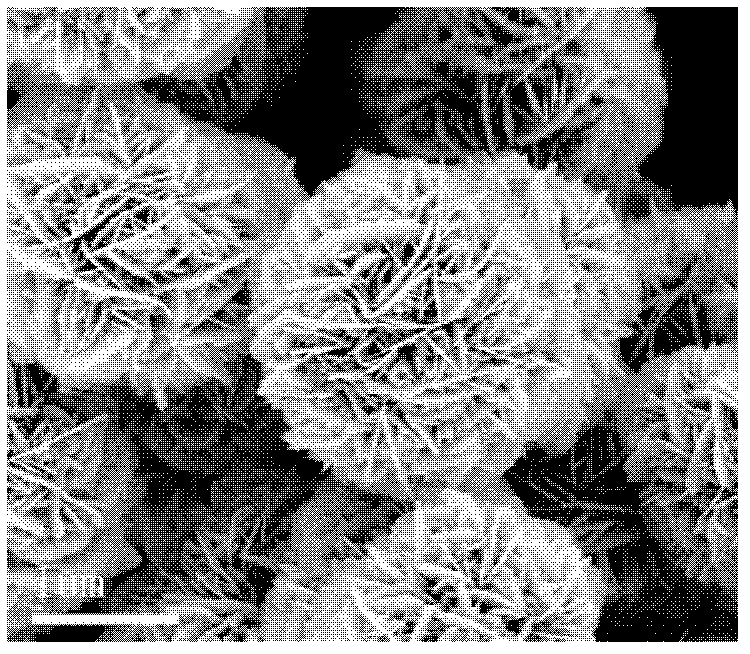

[0025] At room temperature, dissolve 5ml of oleic acid in 15mL of absolute ethanol, prepare 15mL of zinc acetate aqueous solution with a zinc ion molar concentration of 0.5mol / L, and 10mL of a sodium hydroxide solution with a molar concentration of 5mol / L, and then stir with a glass rod. Slowly pour 15 mL of the zinc salt solution into the sodium hydroxide solution to give a clear aqueous solution. Then, 20 mL of oleic acid mixed with ethanol was quickly poured into the obtained clear liquid, and a white precipitate was obtained after standing still. Clean the precipitate by centrifugation and put it in an oven at 90°C for 3.5 hours to obtain zinc oxide microspheres constructed of nanosheets. The SEM image is as follows: figure 2 As shown, its TEM image is shown in Figure 4 As shown, the XRD pattern is as Figure 5 shown.

Embodiment 3

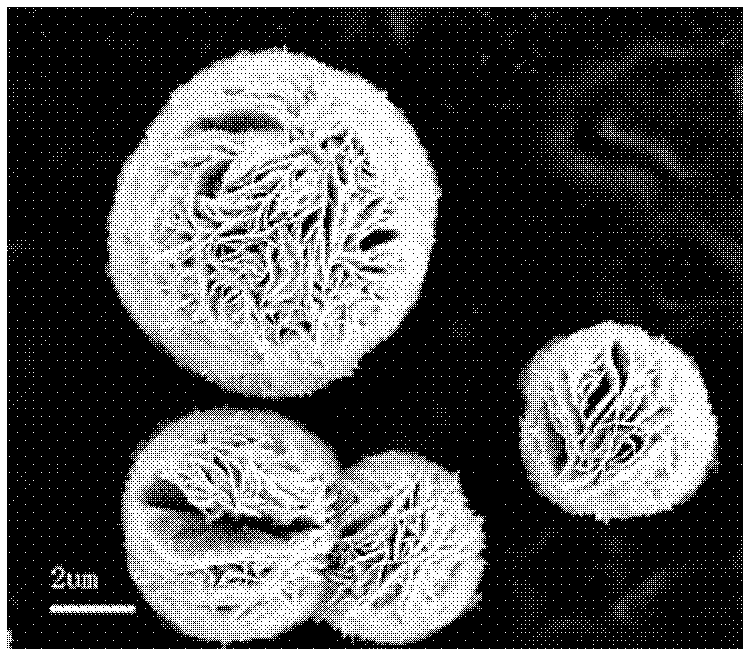

[0027] At room temperature, dissolve 1 g of boric acid in 20 mL of deionized water, prepare 15 mL of zinc nitrate aqueous solution with a molar concentration of zinc ions of 0.5 mol / L, and 10 mL of a sodium hydroxide solution with a molar concentration of 5 mol / L, and then stir with a glass rod to slowly 15mL of zinc salt solution is poured into sodium hydroxide solution, and a clear aqueous solution will be obtained. Then, 20 mL of boric acid solution was quickly poured into the obtained clear solution, and a white precipitate was obtained after standing still. Clean the precipitate by centrifugation and put it in an oven at 70°C for 5 hours to obtain zinc oxide microspheres constructed of nanosheets. The SEM image is as follows: image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com