Polyaniline-graphene composite film and its preparation method, cells and e-books

A composite material thin film, graphene technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of defective material structure, complicated preparation process, can not be used as electrode materials, etc., to achieve good quality and thickness controllable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the preparation method of the polyaniline-graphene composite material film, the preparation method of the aniline-graphene monomer modified electrode includes: the aniline-graphene monomer modified electrode is prepared by preparing a Nafion suspension of graphene and aniline, It is obtained by uniformly coating the Nafion suspension of graphene and aniline on the electrode substrate and drying in a vacuum.

[0038] Specifically, the above-mentioned preparation of the Nafion suspension of graphene and aniline includes: adding graphene and aniline to the Nafion solution at room temperature to fully disperse the suspension; the graphene is 0.002-0.008 g parts by weight, and the aniline is 0.01 -0.09 mL by volume, the Nafion solution is 0.1-5 mL by volume and the concentration is 0.01 to 5 wt%.

[0039] The above-mentioned fully dispersed suspension is specifically: magnetic stirring or ultrasonic oscillation dispersion, magnetic stirring speed 10-60r / min, stirring time 10-5...

Embodiment 1

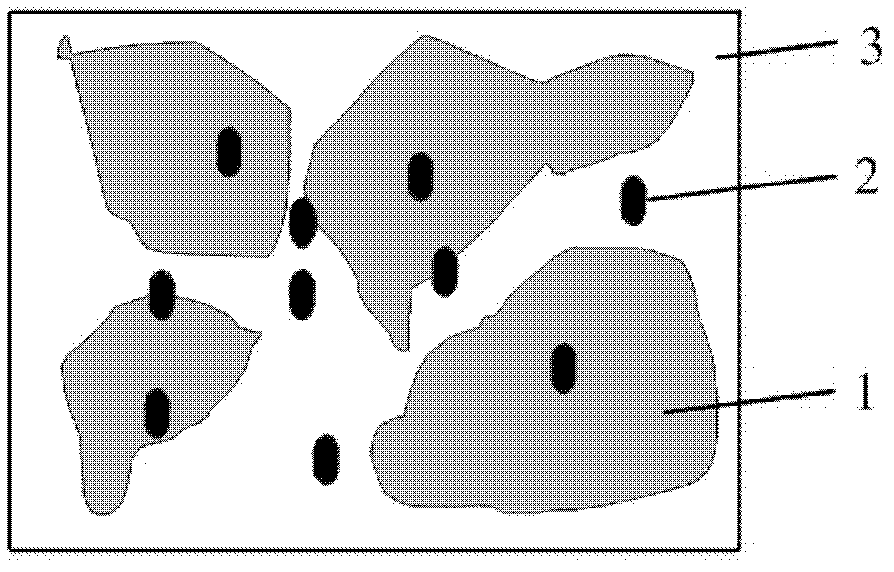

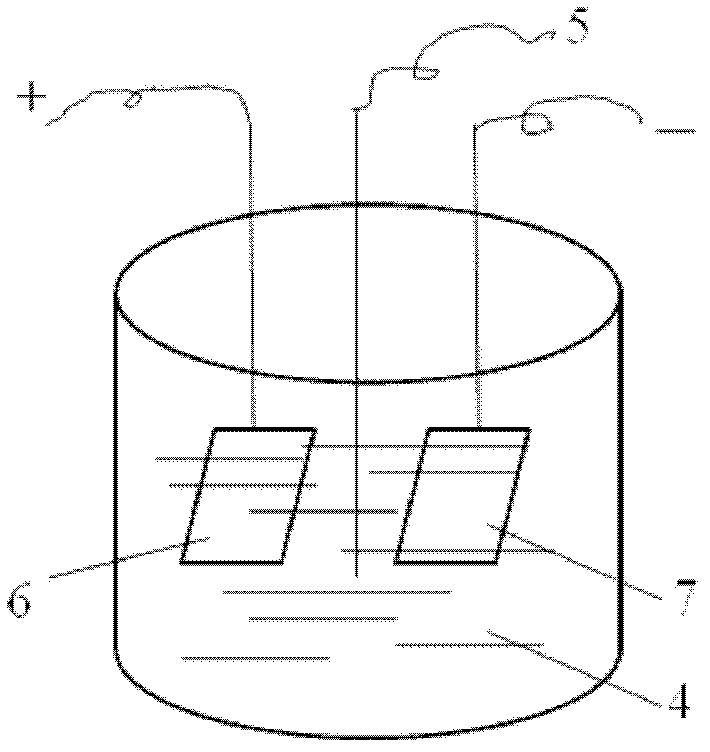

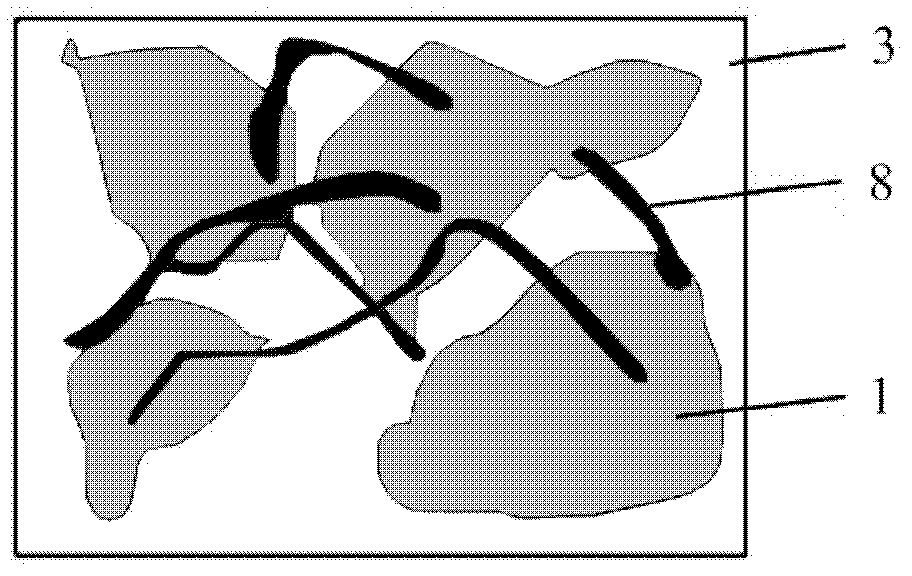

[0054] Add 0.002g of graphene and 0.01mL of aniline to 0.1mL of Nafion solution with a concentration of 0.01wt%, sonicate for 5min, ultrasonic power of 800w, and control the dispersion temperature of ultrasonic vibration at 20℃ through cold water circulation to obtain uniformly dispersed graphene- Aniline suspension. Take 0.01mL of the suspension and spin-coat it on a 12mm2 electrode substrate (polythiophene film), and dry it in a vacuum at 25°C for 30min with a vacuum of 2KPa to obtain an aniline-graphene modified electrode (AN-GNS). figure 1 As shown, 1 is a graphene sheet, 2 is an aniline monomer, and 3 is an electrode substrate. The graphene sheet 1 has an irregular shape, and the aniline monomer 2 is uniformly dispersed on the surface of the electrode substrate 3. It is electropolymerized by constant current method, and the electrolyte is 0.5mol·L -1 HNO 3 Solution, AN-GNS is working electrode, platinum is auxiliary electrode, saturated calomel electrode is reference elec...

Embodiment 2

[0058] Add 0.005g of graphene and 0.05mL of aniline to 2.5mL of Nafion solution with a concentration of 1wt%, sonicate for 30min, ultrasonic power of 800w, and control the dispersion temperature of ultrasonic vibration at 20℃ through cold water circulation to obtain uniformly dispersed graphene-aniline suspension. Take 0.01 mL of the suspension and spin-coated on a 12 mm2 electrode substrate (polythiophene film), and vacuum-dried at 25°C for 30 min with a vacuum degree of 2KPa to obtain an aniline-graphene modified electrode (AN-GNS). It is electropolymerized by constant current method, and the electrolyte is 0.5mol·L -1 HNO 3 Solution, AN-GNS is working electrode, platinum is auxiliary electrode, saturated calomel electrode is reference electrode, current density is 5mA / cm 2 , The polymerization time is 70s, and the thickness of the polyaniline-graphene composite film is about 0.05mm. The test result of the specific capacitance of the composite film is similar to the first emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com