Method for hydrothermally preparing mono-dispersed hollow magnetic nanometer particles

A magnetic nanoparticle, monodisperse technology, applied in the direction of magnetism, nanotechnology, chemical instruments and methods of organic materials/organic magnetic materials, can solve the constraints on the industrialization of hollow magnetic nanoparticles, the large diameter of hollow magnetic nanoparticles, Not suitable for large-scale production and other issues, to achieve the effect of easy large-scale promotion, good dispersion, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

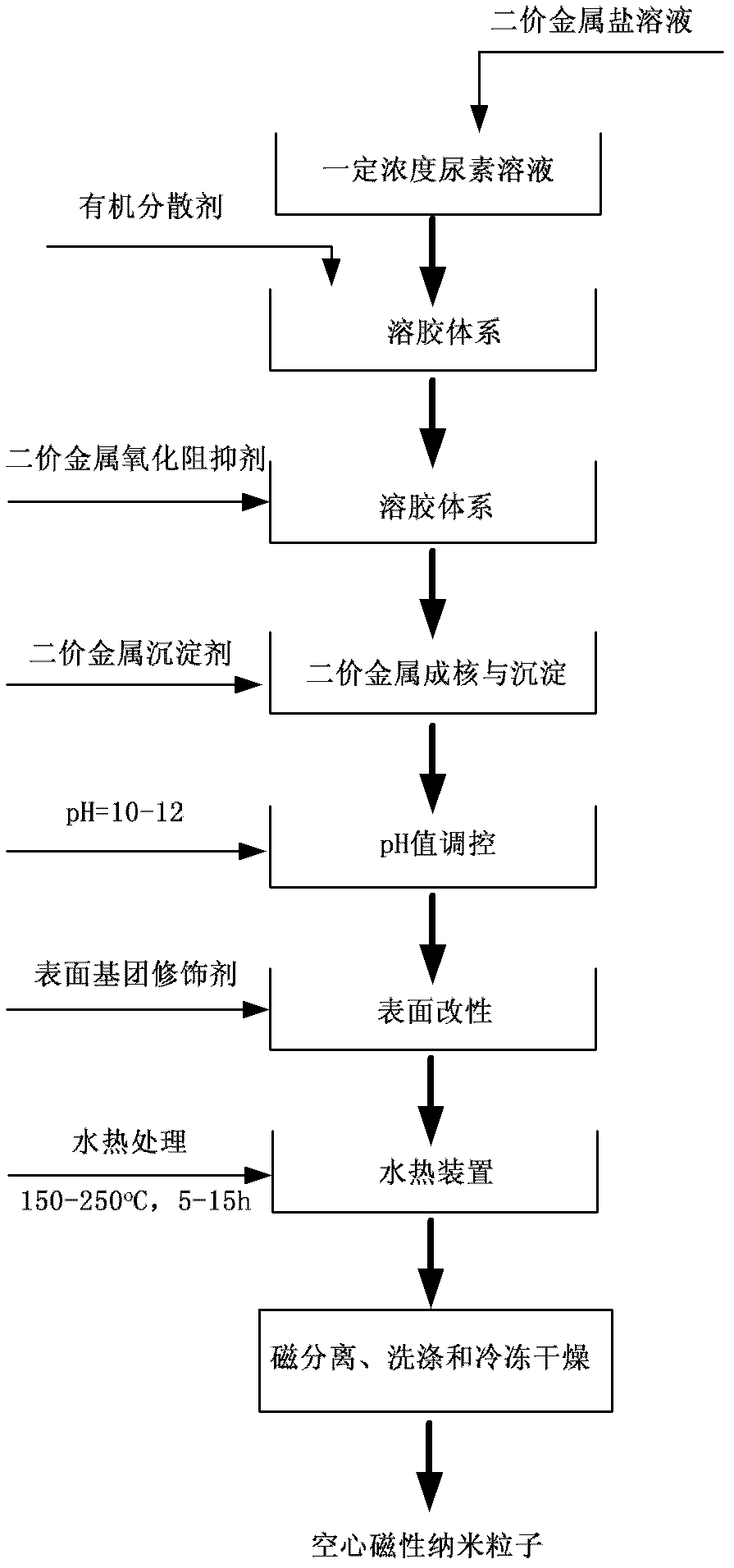

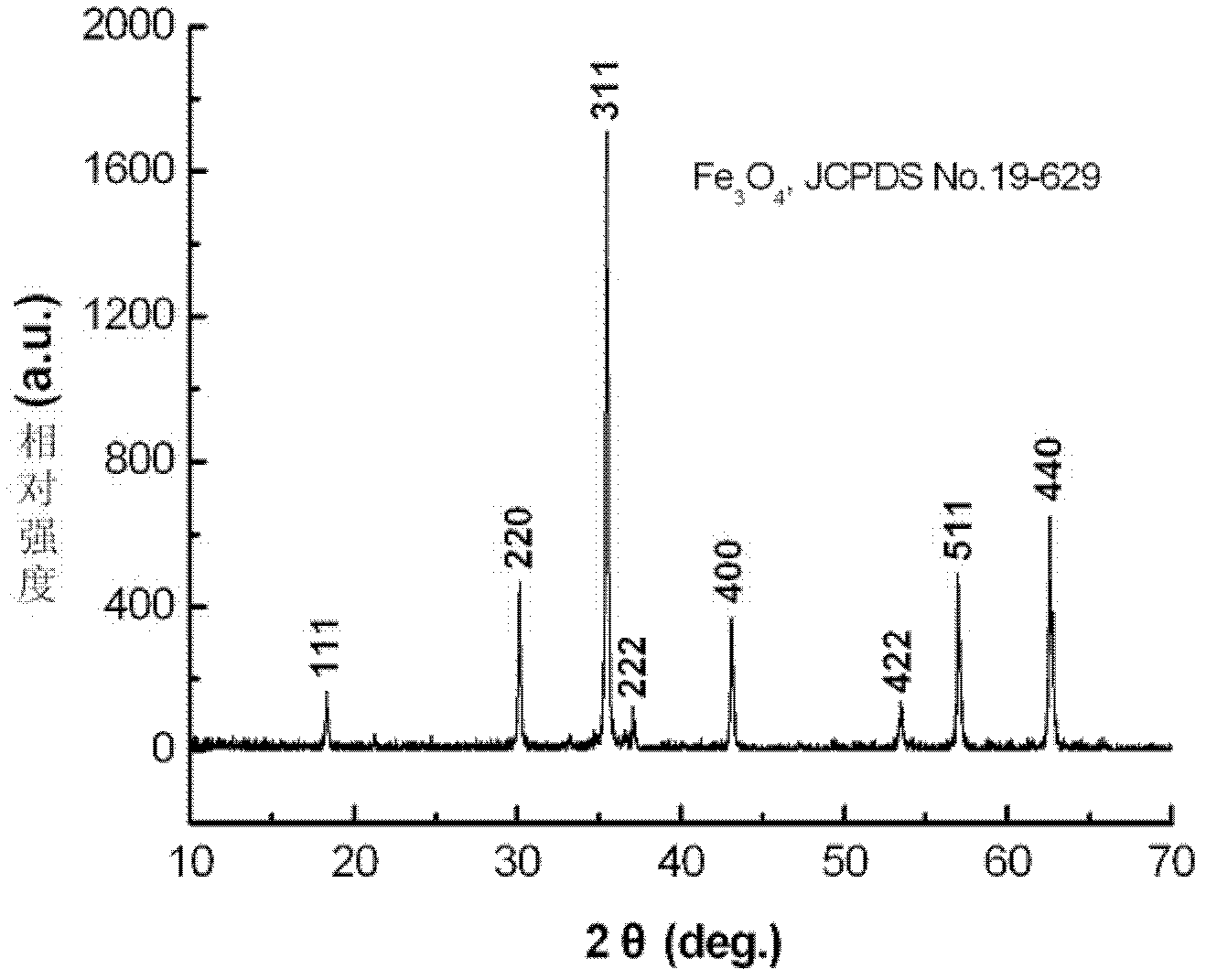

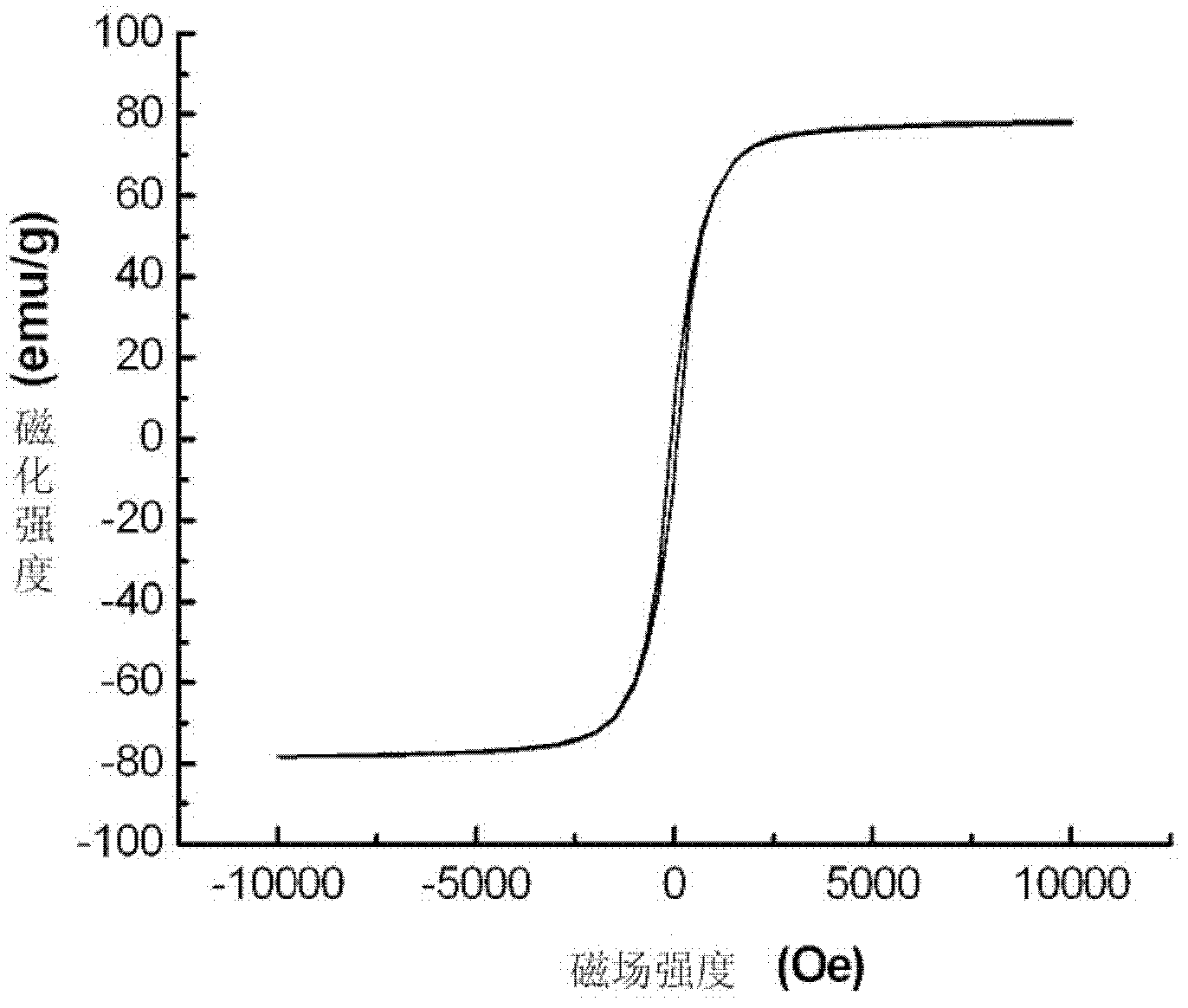

[0039] Such as figure 1 As shown, the technical process for preparing hollow magnetic nano-ions is as follows: configure 20 ml of 0.15 mol / L urea solution, and add 50 ml of 0.4 mol / L FeSO at 25 °C and 750 rpm stirring conditions. 4 solution and 5 milliliters of 0.05 mol / liter of polyvinylpyrrolidone solution, then add 0.05 gram of solid ascorbic acid, after it dissolves completely, add 40 milliliters of 0.2 mol / liter of sodium carbonate solution in the above-mentioned sol mixed solution. After the above solution is fully mixed, adjust the pH value to 10.5 with 0.2 mol / liter sodium hydroxide solution, then add 0.001 mol of ethylenediamine, mix and stir for 30 minutes, transfer to a hydrothermal device, and heat at 200°C for 10 Hour. The product obtained after hydrothermal treatment is separated by magnet, washed with water, washed with alcohol and freeze-dried to obtain a large amount of black hollow magnetic Fe with monodisperse characteristics. 3 o 4 Nanoparticles, particl...

Embodiment 2

[0042] Configure 20 ml of 0.2 mol / L urea solution, and add 30 ml of 0.4 mol / L FeSO at 25°C and 750 rpm stirring conditions 4 solution and 20 mL of 0.4 mol / L CoSO 4 solution, then add 3 milliliters of polyvinyl alcohol-200 (PEG-200) dispersant, add 0.1 gram of solid ascorbic acid to the above solution after mixing, after it is completely dissolved, add 30 milliliters of 0.25 mol / liter of Sodium carbonate solution, adjust the pH value to 11.0 with 0.2 mol / L sodium hydroxide solution, then add 0.0001 mol trisodium citrate, mix and stir thoroughly for 30 minutes, transfer to a hydrothermal device, and heat at 220°C for 10 hours. The black product obtained after hydrothermal treatment is separated by magnet, washed with water, washed with alcohol and freeze-dried to obtain hollow magnetic CoFe with monodisperse characteristics. 2 o 4 Nanoparticles, particle size about 150nm, shell thickness 40nm.

Embodiment 3

[0044] Prepare 20 ml of 0.05 mol / L urea solution, add 40 ml of 0.35 mol / L CoSO at 25°C and 750 rpm stirring conditions 4 solution and 3 milliliters of 0.1 mol / liter cetyltrimethylammonium bromide solution, then add 0.02 gram of solid ascorbic acid, after it is completely dissolved, add 30 milliliters of 0.3 mol / liter carbonic acid sodium solution. After the above solution is fully mixed, adjust the pH value to 10.0 with 0.2 mol / liter sodium hydroxide solution, then add 0.001 mol of ethylenediamine, mix and stir for 30 minutes, then transfer to a hydrothermal device, and heat it at 235°C for 8 Hour. The product obtained after hydrothermal treatment was separated by magnet, washed with water, washed with alcohol and freeze-dried to obtain a large amount of hollow magnetic Co with monodisperse characteristics. 3 o 4 Nanoparticles, particle size about 80nm, shell thickness 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com