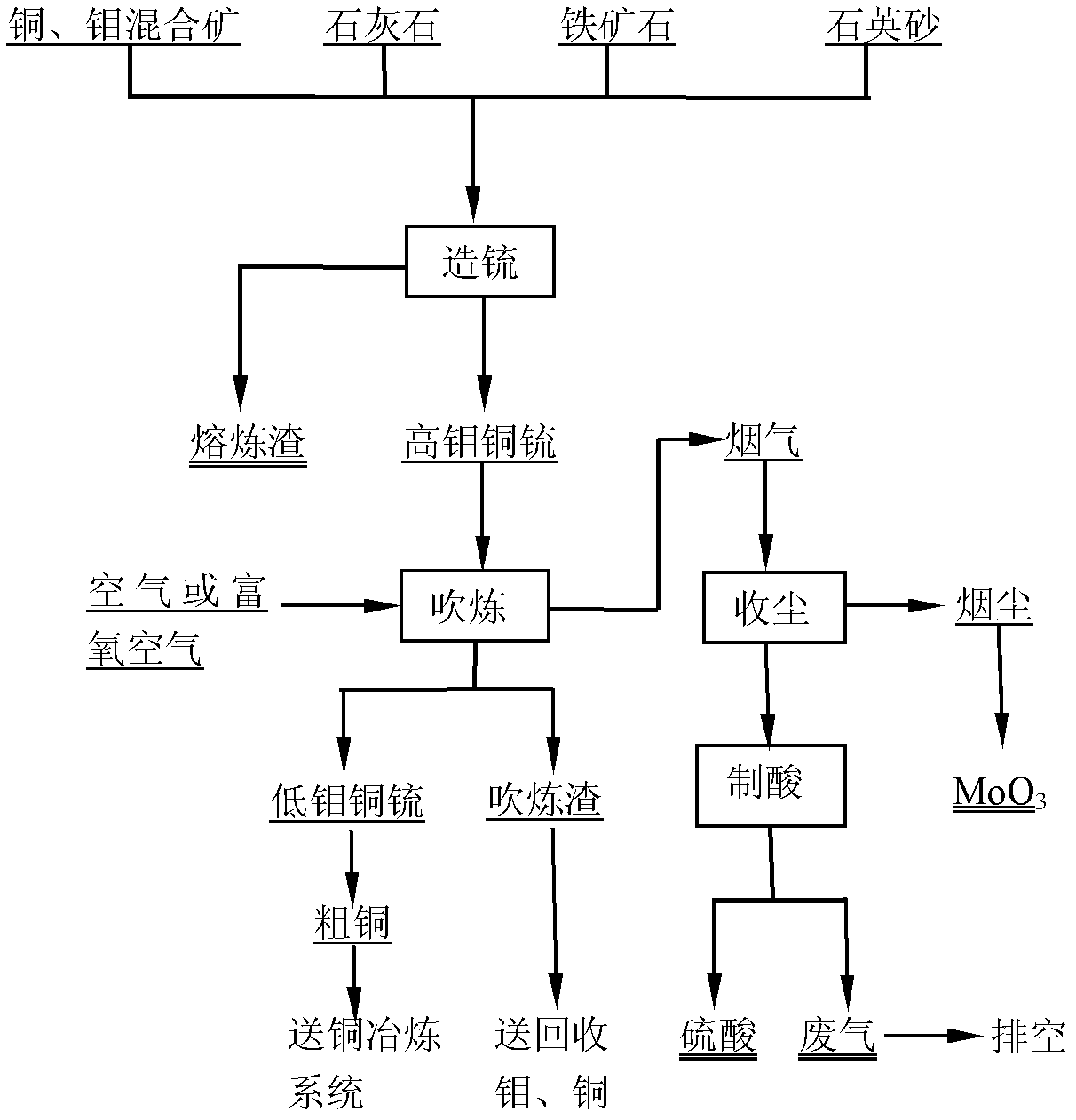

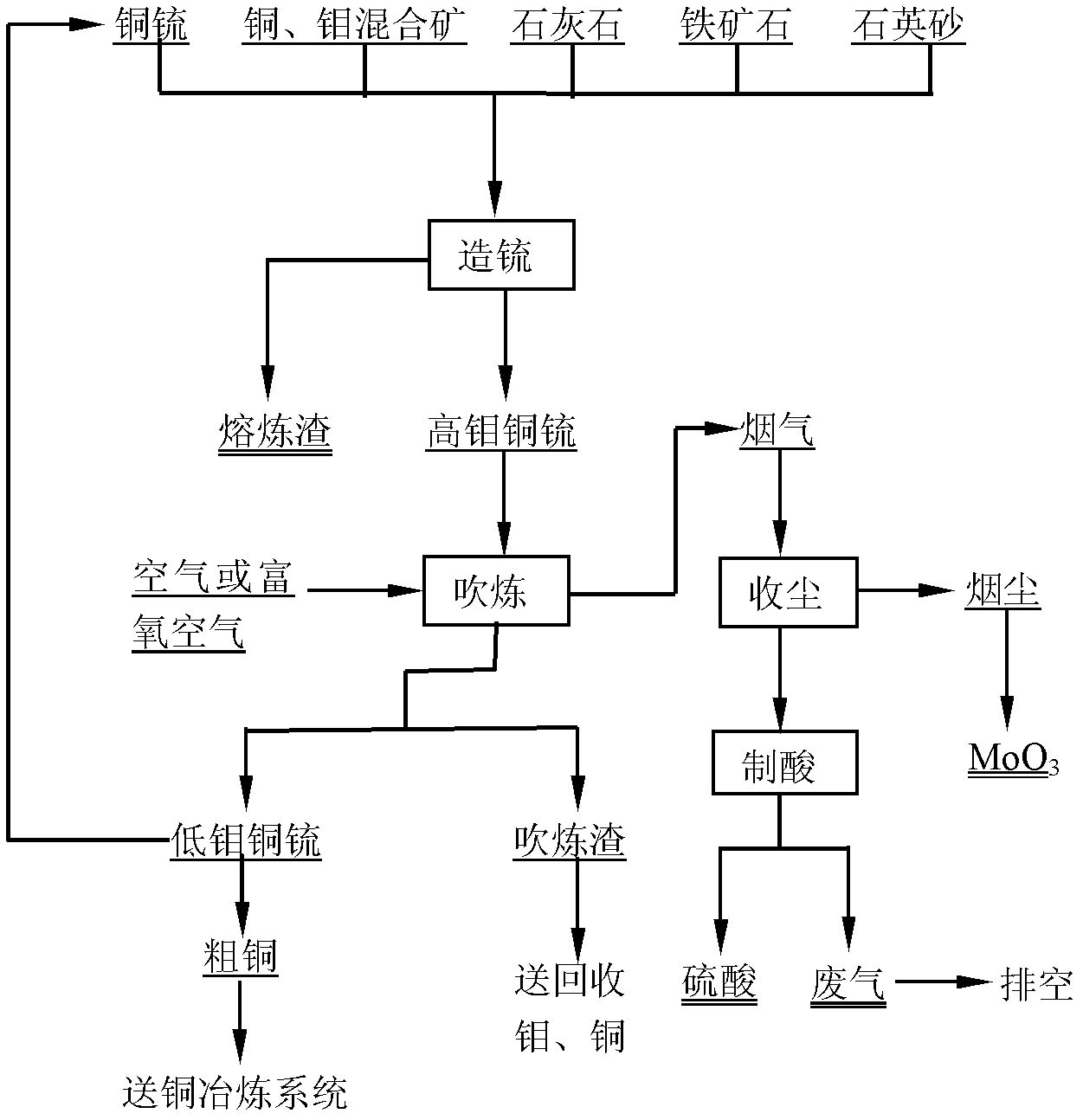

Method for treating copper-molybdenum mixed ores

A technology of mixing ore, copper and molybdenum, applied in the field of molybdenum metallurgy, can solve the problems of complex equipment structure, inconvenient transportation and storage, high melting point, and achieve the effects of simple material preparation process, good heat transfer effect and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] For the composition of Mo 3.00%, Cu 30.20%, S 41.10%, SiO 2 3.60%, CaO 2.40% copper, molybdenum mixed ore, option I is selected, 4.000kg copper, molybdenum mixed ore and 0.250kg quartz sand (containing SiO 2 97.00%), 0.660kg iron ore (with FeO 72.27%) mixed, then put it into the corundum crucible and heat it directly to 1200℃, keep it for 6h, and remove the smelting slag on the surface, totaling 0.840kg. Then pass air into the copper molybdenum matte (flow velocity is 2.5m 3 / h)100min. Obtained 1160kg of blister copper (containing Cu 98.50%, S 0.070%, Mo 0.006%), 0.160kg of soot (containing MoO 3 85.20%), 0.150kg of blowing slag (containing Cu 24.12%, Mo 44.23%), and the flue gas contains SO 2 14.5%.

Embodiment 2

[0043] For the composition of Mo 12.30%, Cu 25.20%, S 36.60%, CaO 1.60%, SiO 2 9.60% copper and molybdenum mixed ore, choose option I, mix 4.000kg copper and molybdenum mixed ore, 0.240kg limestone (containing CaO 45.10%), 0.780kg iron ore (containing FeO 72.27%), and then put into the corundum crucible Directly heat to 1400℃, keep for 10h, and remove the smelting slag on the surface, totaling 1210kg. Then pass oxygen-enriched air (40% oxygen, flow rate 1.5m) into the copper molybdenum matte 3 / h) 120min. Obtained 1.023kg of blister copper (containing 98.3% of Cu, 0.077% of S, 0.004% of Mo), 0.706kg of soot (containing MoO 3 97.50%), 0.144kg of blowing slag (containing Cu 30.06%, Mo 36.13%), SO in flue gas 2 10.2%.

Embodiment 3

[0045] For the composition of Mo 54.00%, Cu 1.50%, S 36.6%, CaO 2.00%, SiO 2 1.20% copper and molybdenum mixed ore, choose option II, mix 1.000kg copper and molybdenum mixed ore with 2.500kg copper matte (containing Cu 75.00%, S 19.40%, Fe 1.28%), and then put it in a corundum crucible for direct heating To 1300℃, keep for 4 hours. Then pass air into the copper molybdenum matte (flow velocity is 2.5m 3 / h) 60min. Obtained 2.100kg of low-molybdenum copper matte (containing Mo 1.63%, Cu 77.30%, S 17.20%), and obtained 0.763 kg of soot (containing MoO 3 98.30%), SO in flue gas 2 7.6%.

[0046] Mix the above-mentioned low-molybdenum copper matte with 0.400kg of copper matte (containing Cu 60.00%, S 29.10%, Fe 7.66%) and add 1.000kg of copper and molybdenum mixed ore (the composition is the same as the aforementioned copper and molybdenum mixed ore in this embodiment ), mix well and put it in a crucible, and heat it to 1300℃ for 4h. Then pass oxygen-enriched air (30% oxygen, flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com