Preparation method for silicon dioxide block layer used for I-III-IV compound solar cell

A technology of I-III-IV and solar cells, applied in the field of solar cells, can solve the problems of reduced cell efficiency and achieve the effects of reduced cross-sectional area, increased barrier efficiency, and low process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

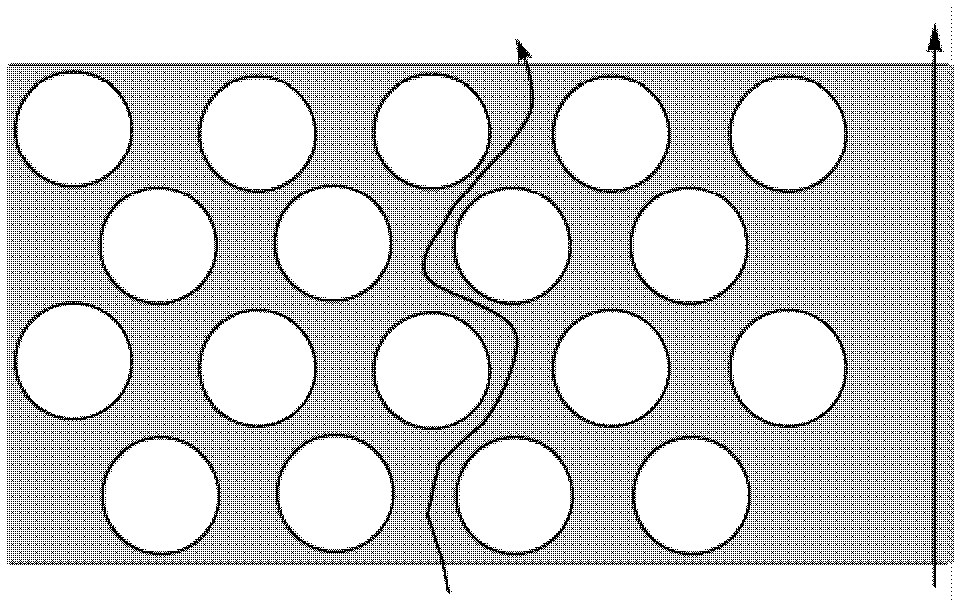

[0016] The embodiment of the present invention is achieved in this way, and provides a method for preparing a silicon dioxide barrier layer for I-III-IV compound solar cells, which includes the following steps:

[0017] S01: Prepare an acid catalyst solution of alkyl orthosilicate, the acid catalyst solution of alkyl orthosilicate contains a molar ratio of 1:(1~5):(0.5~3):(0.001~0.1) Alkyl orthosilicate, isopropanol, H 2 O and HCl;

[0018] S02: Place the acid catalyst solution of the alkyl orthosilicate for 0.5-6h, and then add NH 4 OH solution to obtain silica sol, wherein the alkyl orthosilicate, isopropanol, H 2 The molar ratio of O and HCl is 1:(3-9):(1-6):(0.001~0.1), the NH 4 The molar ratio of OH to HCl is 1:1~4:1;

[0019] S03: Coating silica sol on the medium in an isopropanol atmosphere;

[0020] S04: Continue to age the medium coated with silica sol in an isopropanol atmosphere for 5 to 75 minutes, and then soak in an isopropanol solution to age to obtain an aged gel film;...

Embodiment 1

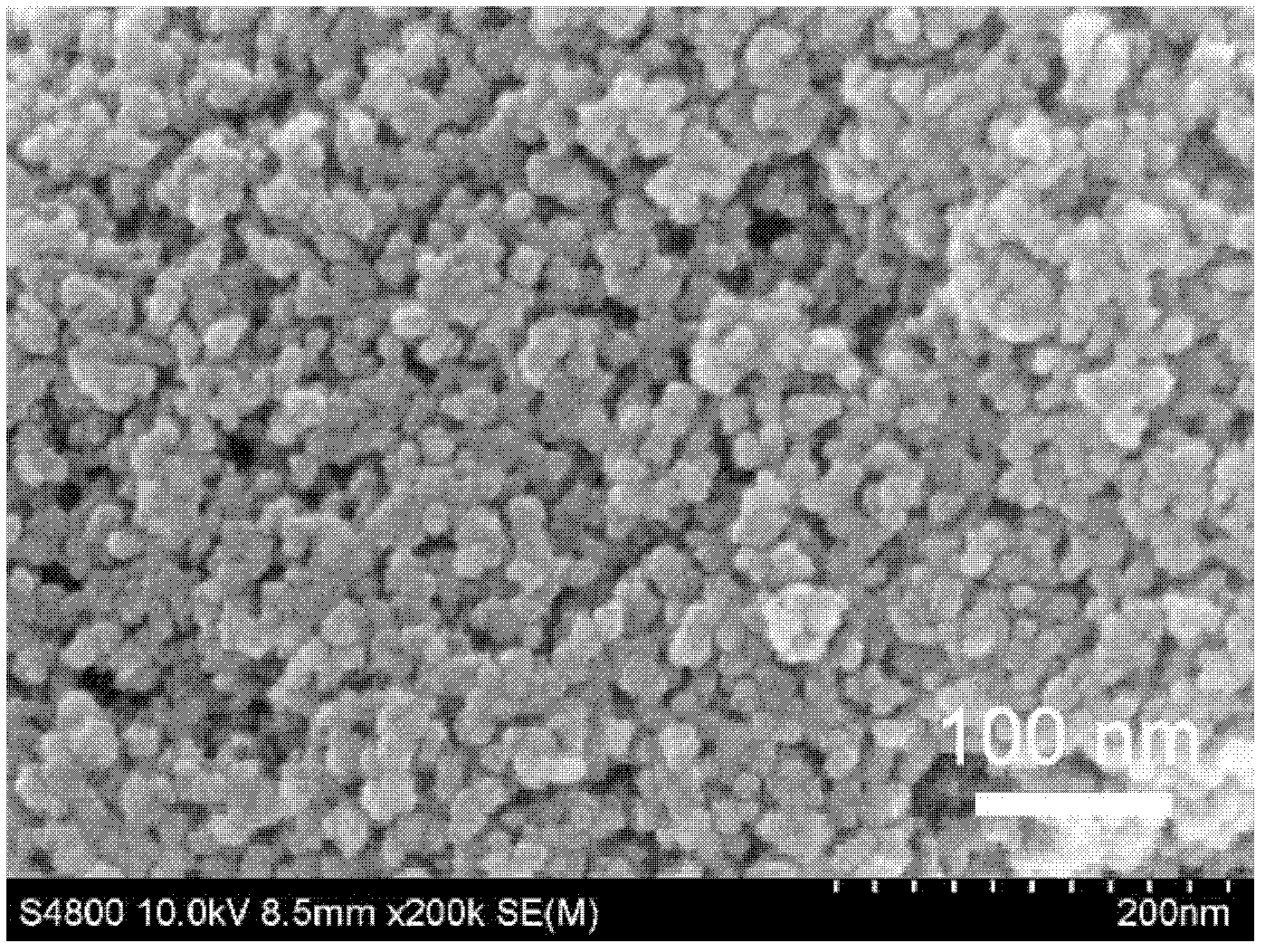

[0030] Under the rapid stirring of a magnetic stirrer, add H dropwise to the mixture of TEOS and isopropanol 2 A mixture of O, HCl and isopropanol to make TEOS: isopropanol: H 2 The molar ratio of O:HCl is 1:3:1:1.8×10 -3 ; After standing for 2h, add H dropwise to the above solution 2 O, NH 4 The mixture of OH and isopropanol makes TEOS: isopropanol: H 2 O:HCl:NH 4 The molar ratio of OH is 1:3:4:1.8×10 -3 : 3.6×10 -3 , To obtain silica sol. Coat a clean silicon wafer with a certain viscosity of silica sol in an isopropanol atmosphere, continue aging in an isopropanol atmosphere for 15 minutes, and then soak in an isopropanol solution for 1 day. The aged wet gel film passes through the N 2 In the atmosphere, the rapid heating and drying in the rapid heat treatment furnace is carried out. The heating process is a heating rate of 20°C / s, rising to 300°C, and then maintaining at this temperature for 30 minutes to obtain the I-III-IV group compound solar cell silica Barrier layer, f...

Embodiment 2

[0032] Under the rapid stirring of a magnetic stirrer, add H dropwise to the mixture of methyl orthosilicate and isopropanol 2 A mixture of O, HCl and isopropanol to make TEOS: isopropanol: H 2 The molar ratio of O:HCl is 1:1:0.5:1×10 -3 ; After standing for 6h, add H dropwise to the above solution 2 O, NH 4 The mixture of OH and isopropanol makes TEOS: isopropanol: H 2 O:HCl:NH 4 The molar ratio of OH is 1:6:6:1×10 -3 : 3×10 -3 , To obtain silica sol. Coat a clean silicon wafer with a certain viscosity of silica sol in an isopropanol atmosphere, continue to age in an isopropanol atmosphere for 75 minutes, and then soak in an isopropanol solution for 3 days. The aged wet gel film passes through the N 2 Under the atmosphere, the rapid heating and drying in the rapid heat treatment furnace, the heating process is the heating rate of 10℃ / s, rise to 500℃, and then keep at this temperature for 75 minutes, and place it in a nitrogen and hydrogen mixed atmosphere for high temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com