Metal complex catalyzer and application thereof for synthesizing cyclic carbonate

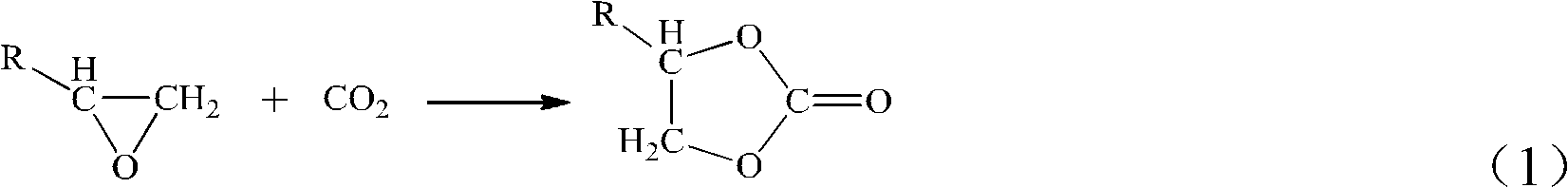

A technology of metal complexes and cyclic carbonates, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical recovery, etc., can solve the problem of lack of suitable catalysts and low usage of homogeneous catalysts , high catalytic activity, etc., to achieve the effects of stable catalyst structure, good repeated use performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 22.52gZnBr 2 and 42.03g of tetraethylammonium bromide were dissolved in 100ml and 50ml of absolute ethanol respectively, then the two were mixed, heated and boiled to 50°C, and maintained for about 30min, cooled to room temperature, filtered, and dried at 60°C under vacuum , to obtain 59.56g white powder [(C 2 h 5 ) 4 N] 2 ZnBr 4 catalyst.

Embodiment 2

[0045] In the autoclave, add the zinc complex [(C 2 h 5 ) 4 N] 2 ZnBr 4 Catalyst 0.17mmol; CO was introduced after sealing 2 Replace the air 2-3 times, measure and press 0.5mol of ethylene oxide, add CO 2 Increase the pressure to 2.5MPa; raise the temperature to 90°C for 40 minutes, when the pressure is lower than 3MPa, add CO 2 to 3MPa, until the still pressure remains constant; cooling, taking out the still liquid and adopting rectification under reduced pressure to obtain the ethylene carbonate product, weighing and analyzing with gas chromatography, the yield of ethylene carbonate is 99.5%, and the TOF in terms of metal complexes is 4390h -1 .

Embodiment 3

[0047] In the autoclave, the zinc complex [(C 2 h 5 ) 4 N] 2 ZnBr 4 Catalyst 0.22mmol and propylene oxide 0.5mol; 2 Replace the air 2-3 times, increase the pressure to 2.5MPa; raise the temperature to 90°C for 40 minutes, when the pressure is lower than 3MPa, add CO 2 To 3MPa, until the pressure of the still remains constant; cooling, taking out the still liquid and adopting vacuum distillation to obtain the propylene carbonate product, weighing and analyzing with gas chromatography. The yield of propylene carbonate is 99.2%, and the TOF calculated as metal complex is 3382h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com