Nano composite material based on titanium metal surface and preparation method thereof

A technology of nanocomposite materials and titanium metal, which is applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problems that cannot meet the functional design requirements, and the composition and structure of the nano-titanium oxide thin film are single.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

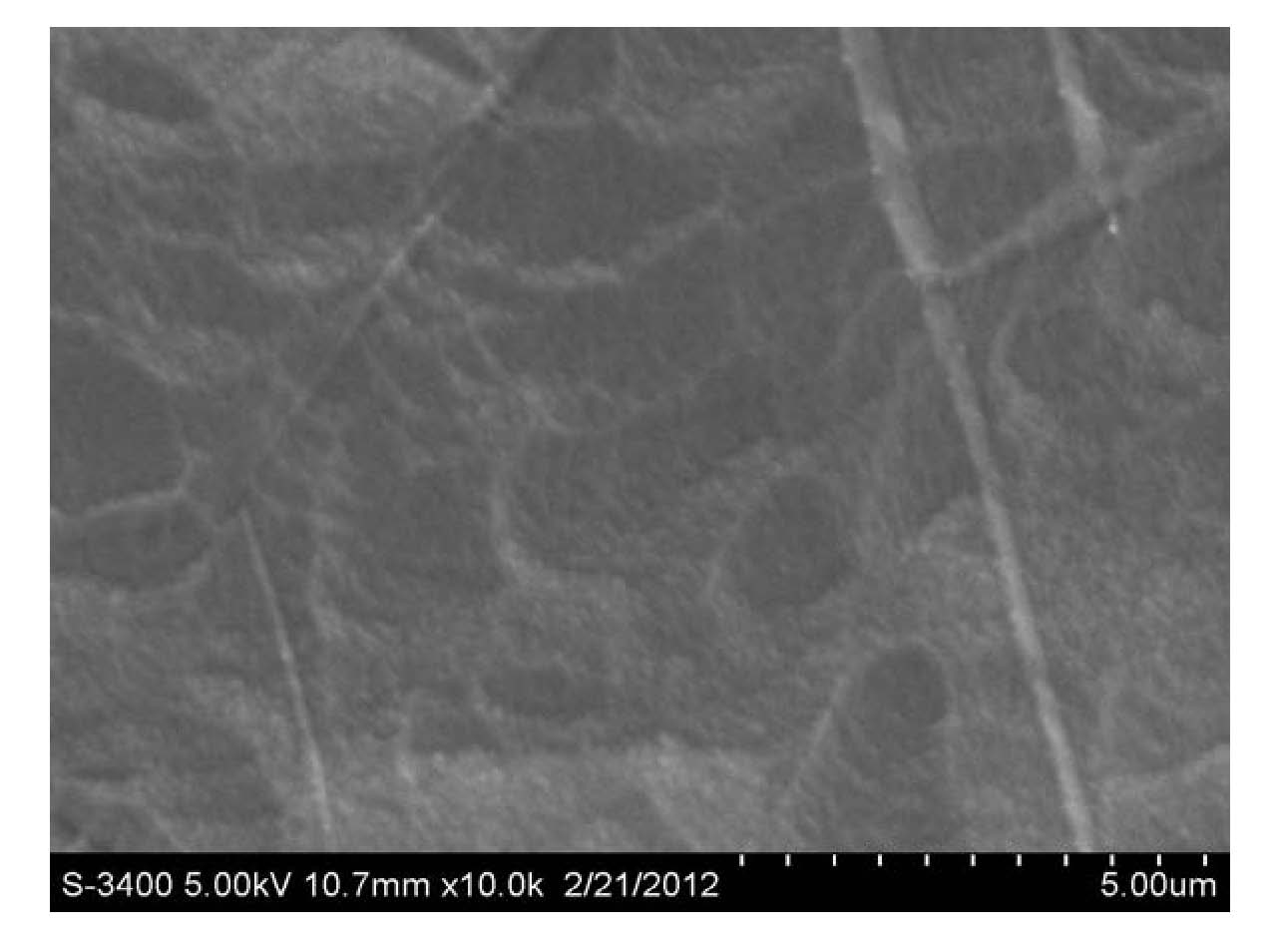

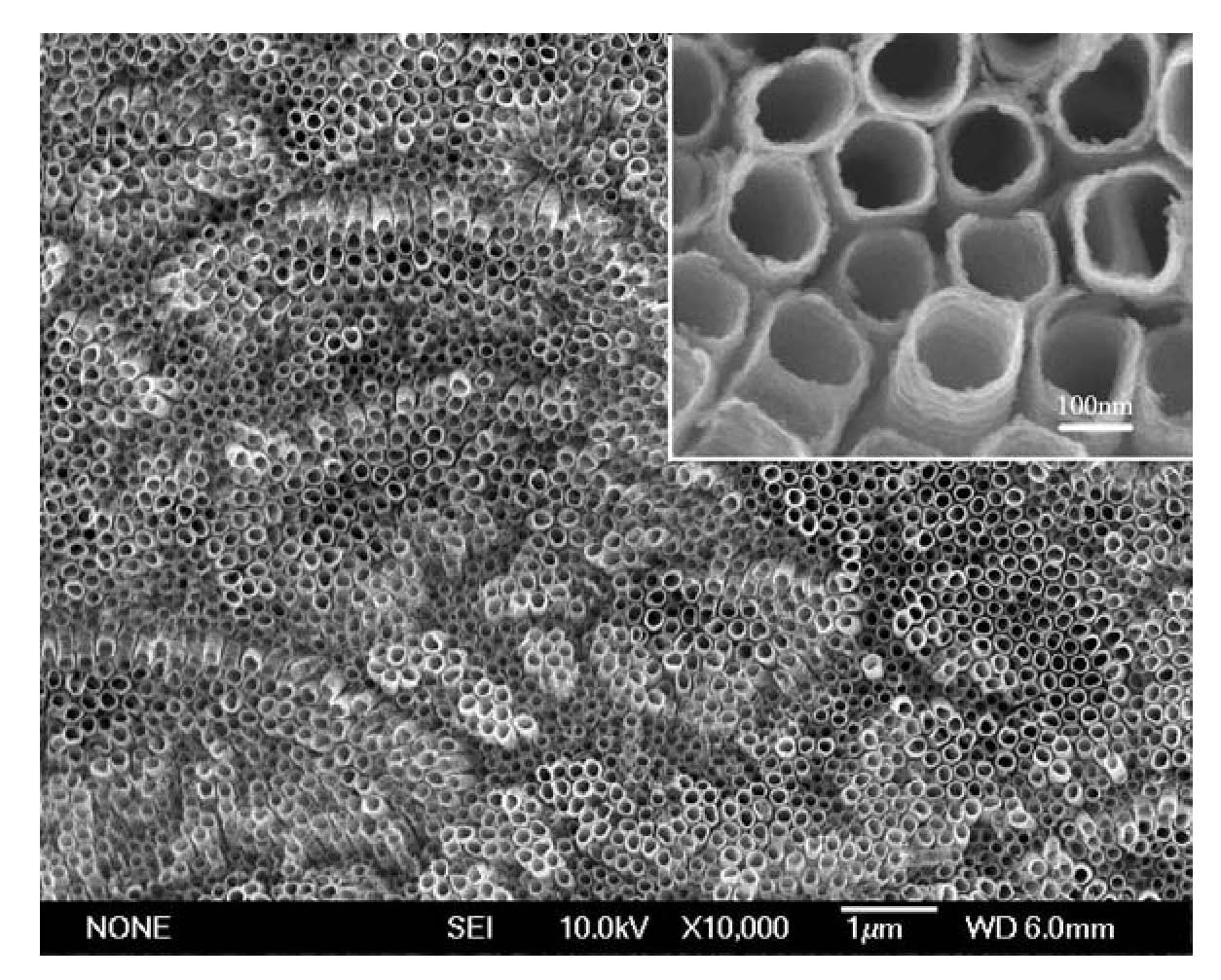

[0036] (1) After the pure titanium metal sheet of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone, alcohol and deionized water in sequence, each time for 15 minutes, to obtain a clean and uniform surface (see figure 1 shown). Anodic oxidation technology is used to in-situ oxidize the surface of titanium metal to form a regular titanium oxide nanotube array film. The specific process conditions and parameters are shown in Table 1. The surface topography images obtained under the process parameters are shown in Figure 2a As shown, the results show that a regular nanotube array structure is formed on the surface of titanium metal;

[0037] Table 1 Anodizing process conditions and parameters

[0038] .

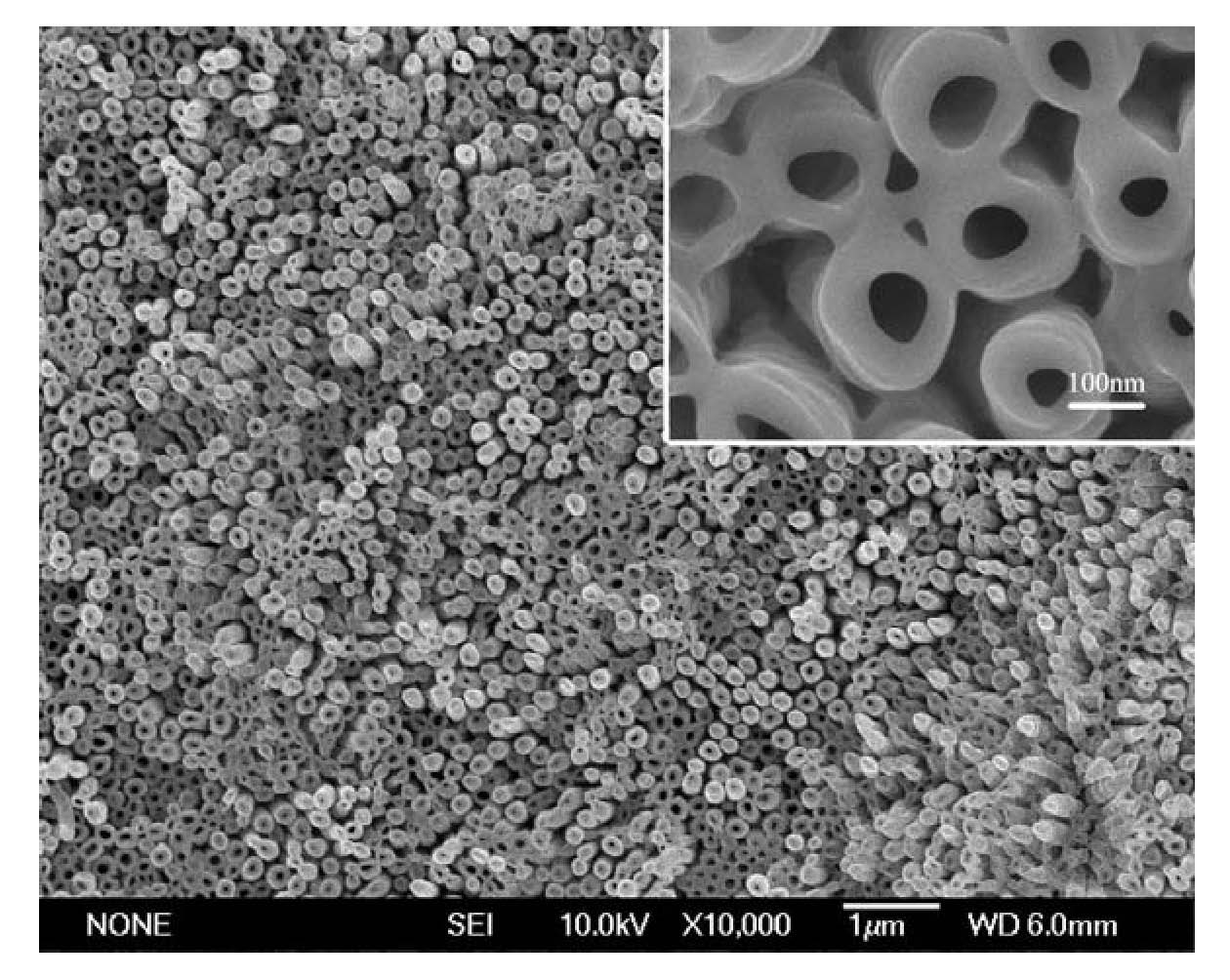

[0039] (2) After drying the regular titanium oxide nanotube array film obtained by the above-mentioned anodic oxidation technology on the surface of titanium metal, plasma immersion ion implantation technology is used to treat the regular titanium oxide...

Embodiment 2

[0046] Steps (1) and (2) of this embodiment are the same as in Embodiment 1, and the detailed description thereof will be omitted. (3) The carbon-containing titanium oxide nanotube film obtained by treating the surface of the titanium metal with the anodic oxidation technique and plasma immersion ion implantation of the plasma immersion ion implantation in the above-mentioned embodiment 1 was subjected to plasma immersion ion deposition treatment. The specific carbon ion deposition parameters are shown in Table 4; the surface topography obtained under the deposition parameters is shown in Figure 2d As shown, the results show that the morphology of the regular titania nanotube arrays is completely replaced by the arrays of nanoconical structures. The top of the single nanotube and the carbon deposition coating form a cone-shaped cap to form a closed structure, but it can be seen from the part of the damaged part that the top nano-conical cap maintains a hollow structure, as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com