Catalyst for eliminating chlorine-containing volatile organic compounds by low-temperature catalytic combustion

An organic compound, low-temperature catalysis technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, combustion methods, etc., can solve the application limitations of precious metal catalysts, expensive precious metal catalysts, chlorination reaction The problem of high activity is to achieve the effect of convenient and practical technical route, low price and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

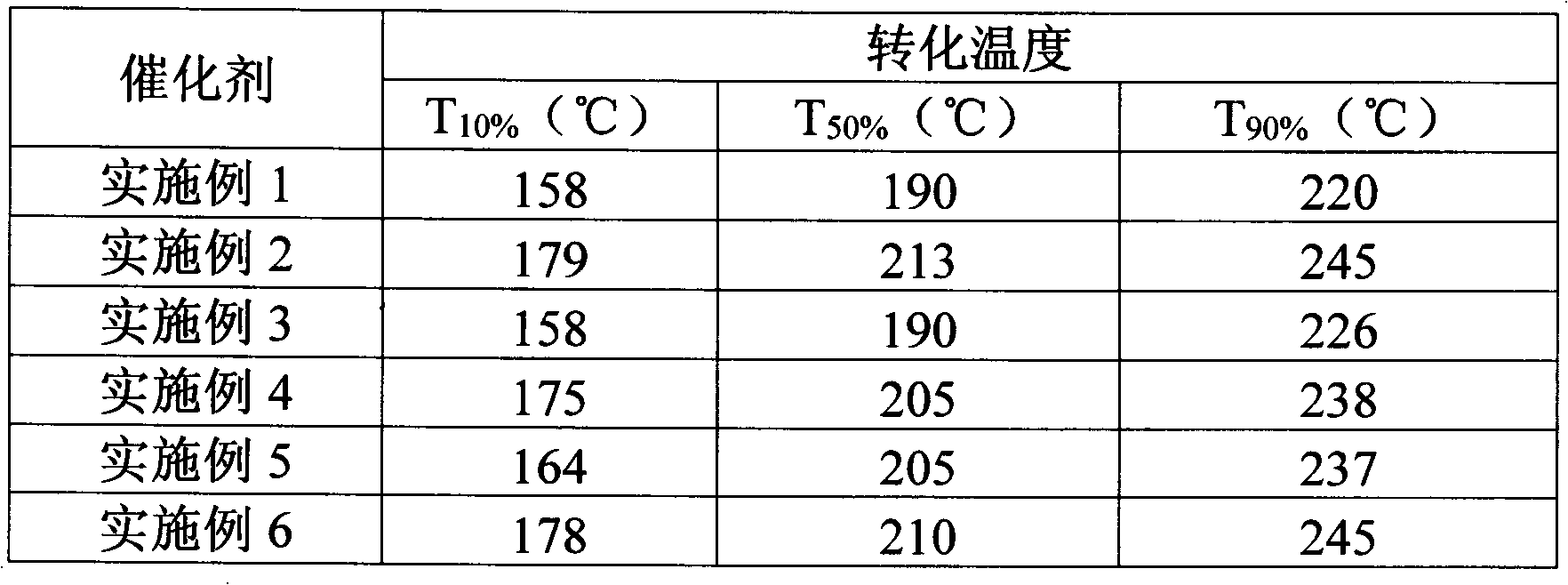

Examples

Embodiment 1

[0016] Dissolve 10g of commercially available cerium nitrate hexahydrate in 20ml of deionized water, then add 0.21ml of tetrabutyl titanate dropwise to the above solution, and stir for 30min as solution A; after mixing 7.5g of sodium hydroxide and 50ml of deionized water As solution B; add solution B dropwise to solution A under vigorous stirring, stir at room temperature for 2 hours, let stand and age for 48 hours, then suction filter, wash, dry, and then transfer to a muffle furnace for roasting. The specific roasting process is as follows: start heating at 50°C, program temperature increase at a heating rate of 2.5°C / min, and maintain at 450°C for 3 hours to obtain a titanium oxide-cerium oxide composite oxide with an atomic ratio of titanium to cerium of 5:95. After removal, the catalyst was ground to ensure that the catalyst was in powder form.

[0017] Commercially available ruthenium chloride was formulated into a 20 g / L aqueous solution, and 2 ml of the solution was im...

Embodiment 2

[0019] Dissolve 10g of commercially available cerium nitrate hexahydrate in 20ml of deionized water, then add 0.18ml of titanium tetrachloride dropwise to the above solution, and stir for 30min as solution A; after mixing 7.5g of sodium hydroxide and 50ml of deionized water As solution B; under strong stirring, solution B was added dropwise to solution A, stirred at room temperature for 2 hours, left to age for 48 hours, then suction filtered, washed, dried, and then transferred to a muffle furnace for roasting. The roasting process was the same as in Example 1. Similarly, a titanium oxide-cerium oxide composite oxide having a titanium-cerium atomic ratio of 5:95 was obtained. After removal, the catalyst was ground to ensure that the catalyst was in powder form. Carry ruthenium oxide by the same method of embodiment 1, prepare catalyst 1%Ru / Ti-CeO 2 (5:95)-2.

Embodiment 3

[0021] Prepare titanium oxide content by the same method of embodiment 1 and be 10% catalyst 1%Ru / Ti-CeO 2 (1:9).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com