Poly semicarbazide acid ester flame retardant foam plate and preparation method

A polyurethane and flame-retardant foam technology, which is applied in the field of flame-retardant foam boards, can solve the problems of polyurethane foam mechanical properties reduction, uneven cell structure, and foam modulus reduction, so as to improve molecular crosslinking density, Ensure overall uniformity and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

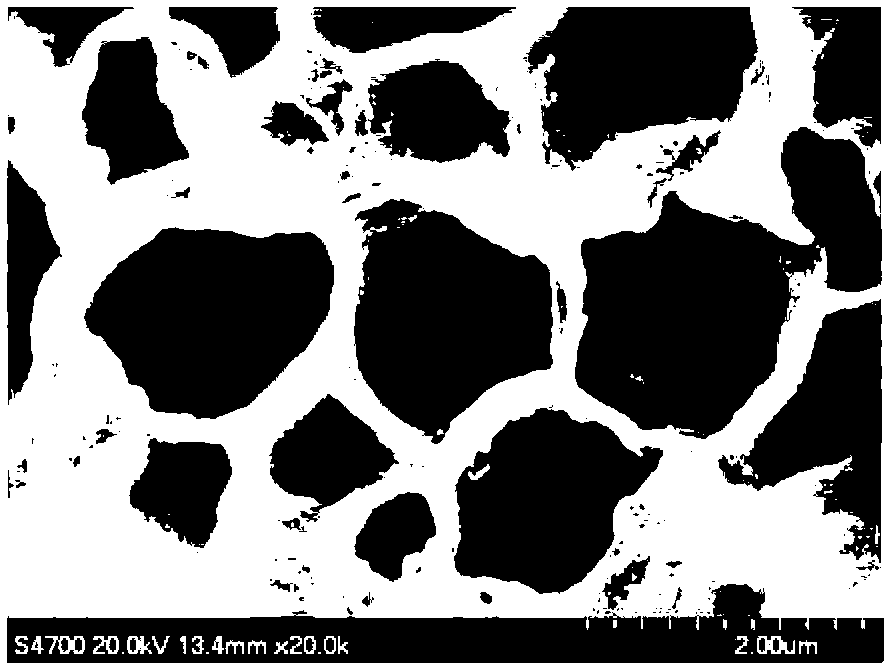

Image

Examples

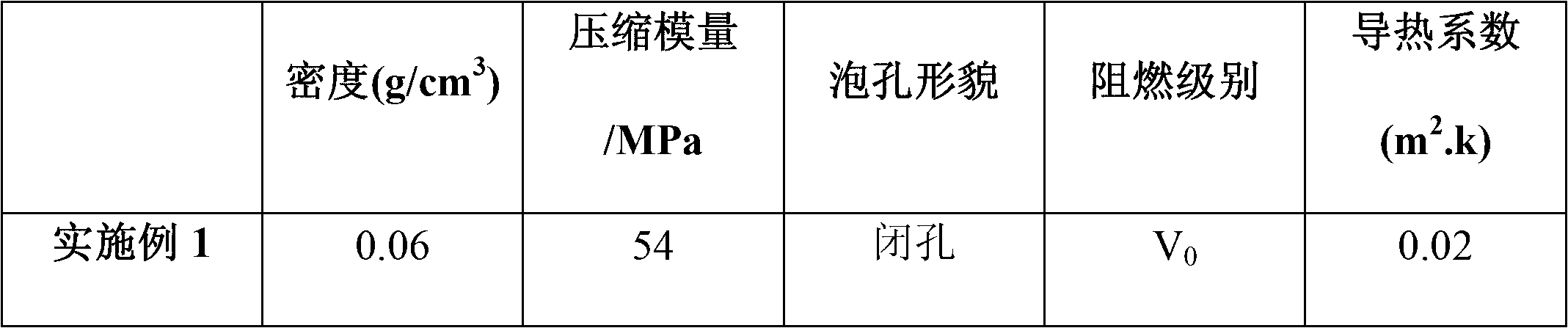

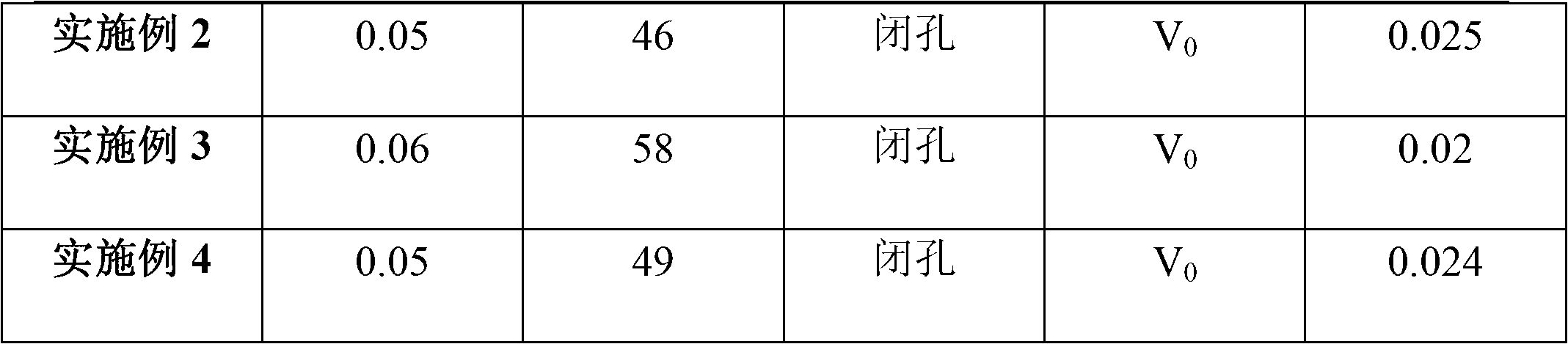

Embodiment 1

[0027] 5.0Kg of MDI, 2.0Kg of hydroxyl-terminated polyethylene terephthalate with molecular weight of 400, 0.2g of chlorinated hydroxyl-terminated polybutadiene (molecular weight of 400, chlorine content of 20wt%), 8.6Kg of Put chlorinated paraffin, 0.4Kg of acetone, 0.6Kg of methyl acetate, and 0.6Kg of dichloromethane into a high-speed mixer, and mix at room temperature for 15 minutes; then add 0.7g of dibutyltin dilaurate and 1.5g of DMP- 30, and mix for 1 minute at room temperature to obtain a precursor slurry.

[0028] Add the precursor slurry into the single-screw extruder, and control the temperature of each section: the first section is 30°C, the second section is 100°C, the third section is 165°C, and the fourth section is 170°C.

[0029] The temperature control of each section of the die head is as follows: the first section is 125°C, the second section is 65°C, the third section is 40°C, and the fourth section is 25°C. Extrude to obtain a foam sheet.

[0030] The ...

Embodiment 2

[0032] 3.5Kg of MDI, 2.0Kg of hydroxyl-terminated polyethylene terephthalate with a molecular weight of 400, 0.5g of chlorinated hydroxyl-terminated polybutadiene (molecular weight of 1000, chlorine content of 20wt%), 8.0Kg of Put chlorinated polyethylene, 0.3Kg of acetone, 0.5Kg of methyl acetate, and 0.5Kg of methylene chloride into a high-speed mixer, and mix at room temperature for 15 minutes; then add 0.6g of zinc carboxylate and 1.2g of DMP-30 , mixed at room temperature for 1 minute to obtain a precursor slurry.

[0033] Put the precursor slurry into a sealed mold at 155°C, press at 20MPa, and after 20 minutes of molding, pass water to cool to 25°C and open the mold.

[0034] The extruded foam board was placed in an environment with a humidity of 85% and a temperature of 50° C. for post-curing reaction for 1 day. A polyurethane foam board was obtained.

Embodiment 3

[0036] 5.0Kg of MDI, 2.0Kg of polytetrahydrofuran diol with a molecular weight of 400, 0.2g of chlorinated hydroxyl-terminated polybutadiene (with a molecular weight of 400 and a chlorine content of 25wt%), 8.6Kg of polyvinyl chloride, and 0.4Kg of acetone , 0.6Kg of methyl acetate and 0.6Kg of dichloromethane were put into a high-speed mixer and mixed for 15 minutes at room temperature; then 0.7g of bismuth carboxylate and 1.5g of DMP-30 were added and mixed for 1 minute at room temperature to obtain a precursor slurry.

[0037]Add the precursor slurry into the single-screw extruder, and control the temperature of each section: the first section is 30°C, the second section is 100°C, the third section is 165°C, and the fourth section is 170°C. The temperature control of each section of the die head is as follows: the first section is 125°C, the second section is 65°C, the third section is 40°C, and the fourth section is 25°C. Extrude to obtain a foam sheet.

[0038] The extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com