High-density high-rigidity graphene porous carbon material as well as preparation method and applications thereof

A technology of porous carbon and graphene, applied in the field of graphene, can solve the problems of graphene formability, low strength, uneven molded products, and difficulties in practical application, so as to improve the doping range and uniformity, and reduce the critical reaction time , the effect of rich pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

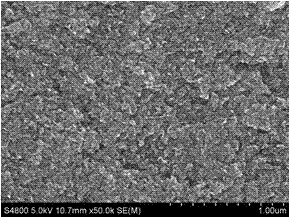

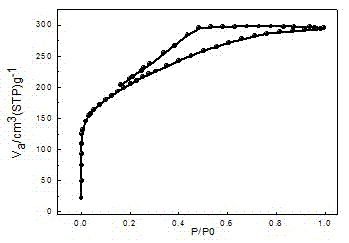

[0055] Weigh 170 mg of graphite oxide powder material prepared by the Hummer method, add 85 mL of deionized water, and ultrasonically disperse for 2 h at a power of 200 W to obtain a graphene oxide hydrosol; adjust the pH of the above sol to about 3, and uniformly disperse the above The graphene oxide hydrosol was placed in a 100 mL hydrothermal reaction kettle, and the hydrothermal reaction kettle was placed in a muffle furnace with a temperature of 150 °C for 6 h; after the hydrothermal reaction kettle was cooled, the inner tank was opened, and the water phase was poured out. , to obtain a smooth cylindrical material, that is, graphene-based gel, which was dried at 1 °C; then it was heated to a temperature of 700 °C at 5 °C / min under an argon protective atmosphere, and a high temperature was obtained after constant temperature treatment for 5 h. Density and high hardness graphene porous carbon material, the specific surface area of the porous material is 750 m 2 / g, unit v...

Embodiment 2

[0057] Weigh 510 mg of graphite oxide powder material prepared by the Hummer method, add 85 mL of deionized water, and ultrasonically disperse for 2 h at a power of 200 W to obtain a graphene oxide hydrosol; adjust the pH of the above sol to about 8, and the above The uniformly dispersed graphene oxide hydrosol was placed in a 100 mL reaction vessel, and the reaction vessel was heated to a temperature of 500 °C and kept at a constant temperature for 3 h; after the reaction vessel was cooled, the liner was opened, and the water phase was poured out to obtain a smooth cylindrical material. Cut it into thin slices of 1-5 mm and let it dry at room temperature. It was heated up to a temperature of 3600 °C at 5 °C / min under an argon protective atmosphere, and after constant temperature treatment for 2 h, a graphene porous carbon material with high density and high hardness was obtained, and the density of the material was 0.34 g / cm 3 , with a hardness H of 1.68 GPa and a specific su...

Embodiment 3

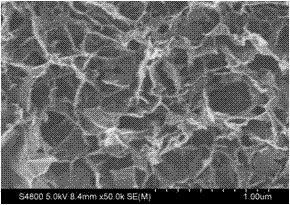

[0059] Weigh 170 mg of graphite oxide powder material and 17 mg of carbon nanotubes prepared by the Hummer method, add 85 mL of dimethylformamide, and ultrasonically disperse for 3 h at a power of 200 W to obtain the original sol; adjust the pH of the above sol to about 3 , put the above homogeneously dispersed original sol in a 100 mL hydrothermal reaction kettle, put the hydrothermal reaction kettle into a muffle furnace at a temperature of 150 °C for 10 h; open the inner tank after the hydrothermal reaction kettle is cooled, pour After leaving the liquid phase, place it at room temperature to dry; then use chemical activation to treat it, that is, soak it in 3 mol / L KOH solution for 24 hours, then dry it, and heat it up to temperature at 10 °C / min under an argon protective atmosphere. 900 ℃, constant temperature for 0.1 h to obtain a high-density and high-hardness graphene porous carbon material with a specific surface area of 2980 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com