Preparation method and application of ordered mesoporous carbon-activated carbon fibrofelt composite material

A technology of activated carbon fiber felt and composite materials, which is applied in the field of preparation of new ordered mesoporous carbon-activated carbon fiber felt composite materials, which can solve the problem that PTFE is easy to block the channels of mesoporous carbon, mesoporous carbon is difficult to use as electrode material, and the electrode can be reduced. Material conductivity and other issues, to achieve excellent catalytic degradation activity and degradation speed, less types and dosage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Product preparation example:

[0035] 1. A new type of ordered mesoporous carbon-activated carbon fiber felt (OMC-ACF) composite material, the preparation steps are as follows:

[0036] (1) Preparation of phenolic resin carbon source:

[0037] Put 0.61g of phenol into a round-bottomed flask, stir to dissolve in a water bath at 40~42℃, then add 0.13g of 20wt% NaOH solution, stir for 10min, add 1.05g of 37wt% formaldehyde solution dropwise, and then heat to 78 After ~80℃, the reaction was stirred for 1h, cooled to room temperature, then 0.6mol / L HCl was dropped to adjust the pH of the reaction system to 7.0, then the water was removed by rotary evaporation at 50℃, and the resulting yellow oily product was used anhydrous Ethanol solution of phenolic resin diluted to 20wt% for use;

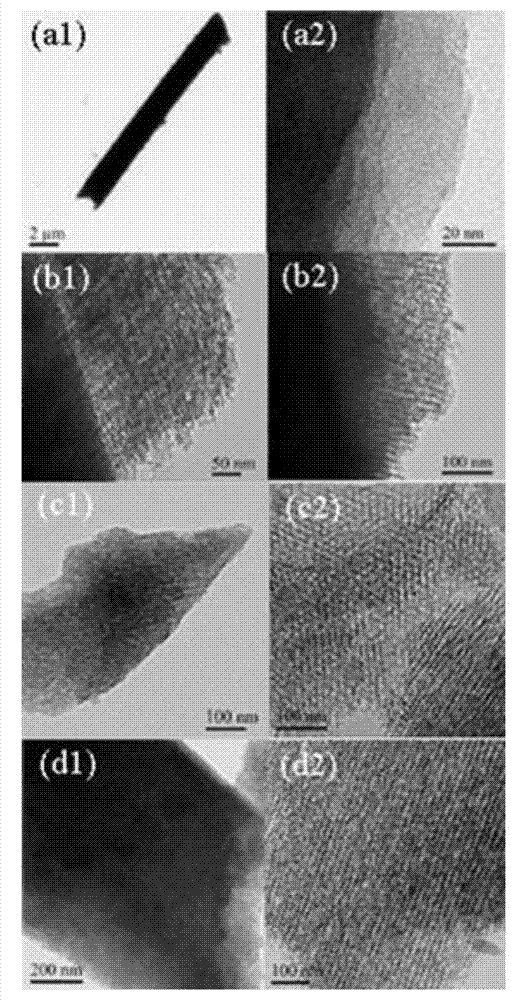

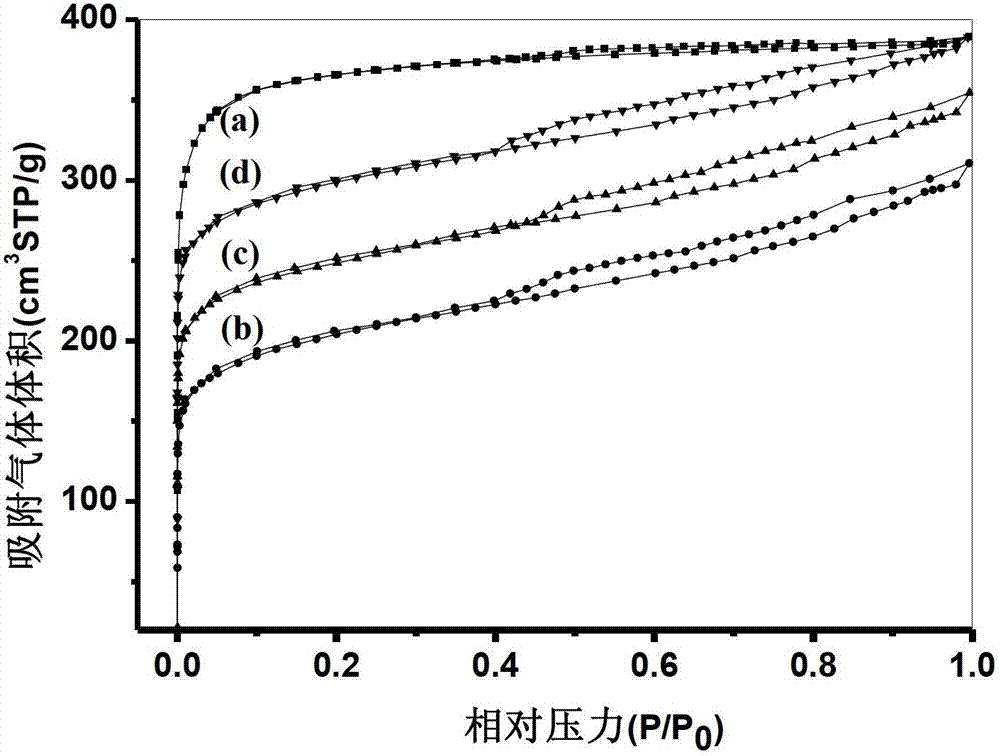

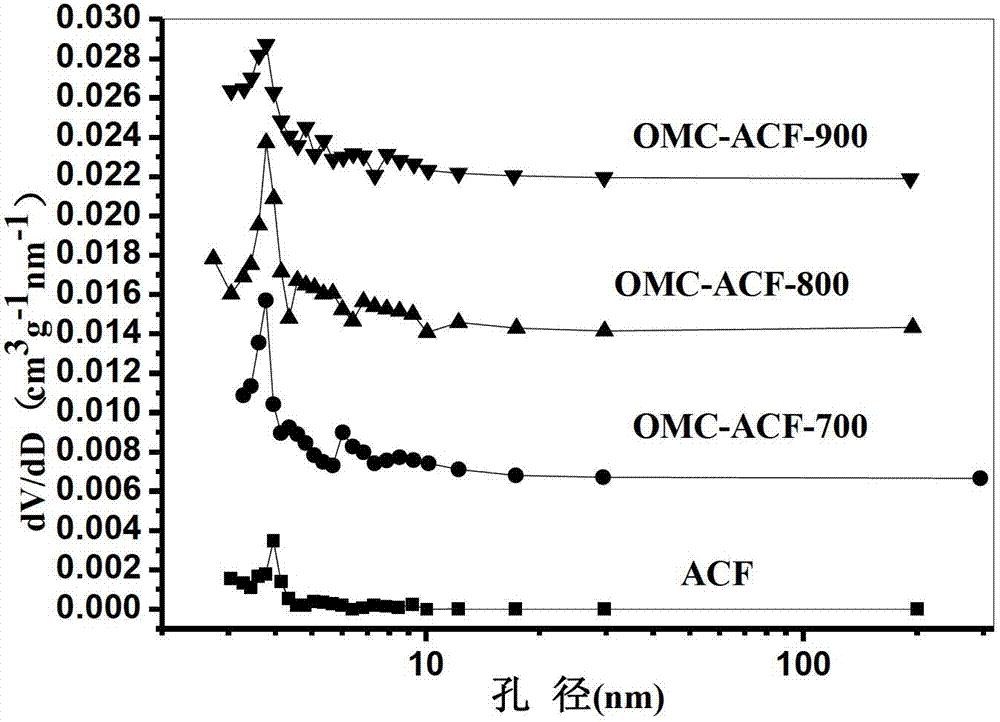

[0038] (2) Preparation of mesoporous carbon-activated carbon fiber felt composite material (OMC-ACF):

[0039] Add 20g of absolute ethanol into the round bottom flask, add 1.0g of non-ionic s...

Embodiment 2

[0044] Example 2 Application Example: The OMC-ACF-x prepared in Example 1 was applied to the electro-Fenton system as an oxygen diffusion cathode to degrade dye wastewater X3B test

[0045] 1. Preparation of electrode:

[0046] Accurately weigh 0.1g of OMC-ACF-x (approximately 3cm×3cm) and wrap it on a 3cm×3cm pure titanium sheet as the cathode, and wrap the same quality ACF on a 3cm×3cm pure titanium sheet as the cathode. Cathode comparison. The activated graphite plate anode GE (3cm×3cm) is combined with ACF and OMC-ACF-x cathodes to form different electrode pairs. The side covered with OMC-ACF-x or ACF is opposite to GE, and the The electrode corresponds to the electro-Fenton system.

[0047] 2. Degradation steps:

[0048] During the electro-Fenton degradation experiment of X3B, X3B wastewater was simulated by X3B aqueous solution. Pass air (flow rate 0.6L / min) on the surface of the cathode to keep the solution saturated with oxygen, and set the volume of 200mL pH=3.0 containing...

Embodiment 3

[0049] Example 3: Test of regeneration performance of OMC-ACF-x prepared in Example 1

[0050] The OMC-ACF-800 electrode after each use in Example 2 was immersed in deionized water for 3 times, and after soaking for 1 hour each time, it was allowed to air dry naturally, and then the operation steps of 2 were repeated. The electrode was repeatedly used 6 times, and the degradation ability of the sixth use remained 84.0% of the first use (see Table 2), indicating that the cathode material has good regeneration performance and can be reused.

[0051] Table 2O MC-ACF-800 regeneration performance test results

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com