Method for preparing oriented graphene nanoribbon (GNR) array

A graphene nanoribbon and array technology, applied in the field of graphene material preparation, can solve the problems of difficult device integration and difficult GNR device performance, and achieve low in-plane defect density, good electrical conductivity, and low edge disorder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

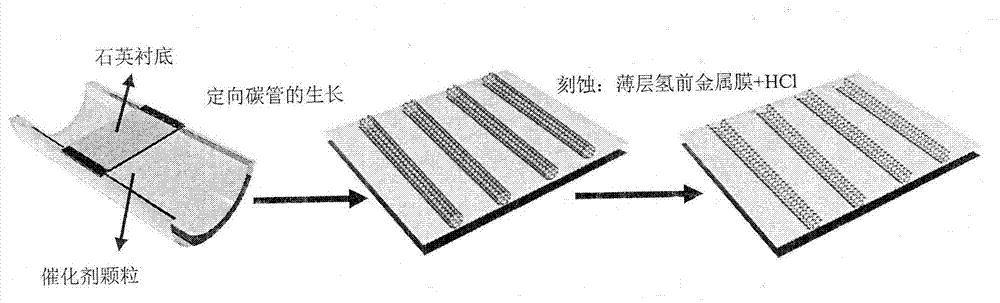

[0033] Embodiment 1 For the technical process of this embodiment, please refer to Figure 1a , which includes the following steps:

[0034] (1) The substrate material is a single-sided polished, constant temperature cut (ST-cut) single crystal quartz plate, where the positioning side X is perpendicular to one side of the quartz plate, the Y deviation Z is 42.75°, and the cutting deviation angle is less than ±0.3° . The substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 5 min respectively), and then dried with nitrogen. The cleaned substrate was annealed at 800° C. for 8 hours in an air atmosphere, and then cooled naturally. Finally, the annealed quartz substrate was ultrasonically cleaned with ethanol and deionized water again and dried with nitrogen.

[0035] (2) Firstly, metal chloride (CuCl 2 ) ethanol solution was dropped on the quartz boat (drop 80 μL). The quartz boat was heated to 450 °C for 25 min in an air atmosphere to oxidize the...

Embodiment 2

[0037] Embodiment 2 The technological process of the present embodiment please be close to embodiment 1, and it comprises the following steps:

[0038] (1) The substrate material is a single-sided polished, constant temperature cut (ST-cut) single crystal quartz plate, where the positioning side X is perpendicular to one side of the quartz plate, the Y deviation Z is 42.75°, and the cutting deviation angle is less than ±0.3° . The substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 1 min respectively), and then dried with nitrogen. The cleaned substrate was annealed at 800° C. for 1 hour in an air atmosphere, and then cooled naturally. Finally, the annealed quartz substrate was ultrasonically cleaned with ethanol and deionized water again and dried with nitrogen.

[0039] (2) First, metal chloride (NiCl 2 ) ethanol solution was dropped on the quartz boat (drop 100 μL). The quartz boat was heated to 400 °C for 25 min in an air atmosphere to o...

Embodiment 3

[0041] Embodiment 3 The technological process of the present embodiment please be close to embodiment 1, and it comprises the following steps:

[0042] (1) The substrate material is a single-sided polished, constant temperature cut (ST-cut) single crystal quartz plate, where the positioning side X is perpendicular to one side of the quartz plate, the Y deviation Z is 42.75°, and the cutting deviation angle is less than ±0.3° . The substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 10 min respectively), and then dried with nitrogen. The cleaned substrate was annealed at 850° C. for 10 hours in an air atmosphere, and then cooled naturally. Finally, the annealed quartz substrate was ultrasonically cleaned with ethanol and deionized water again and dried with nitrogen.

[0043] (2) Firstly, metal chloride (FeCl 3 ) ethanol solution was dropped on the quartz boat (drop 80 μL). In the air atmosphere, the quartz boat was heated to 600 °C for 60 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com