Maca instant tea and production method thereof

A technology of maca instant tea and its production method, which is applied in the field of food processing, can solve the problems that have not yet been found in the literature reports of maca instant tea, and achieve the effects of improving bioavailability, easy acceptance, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

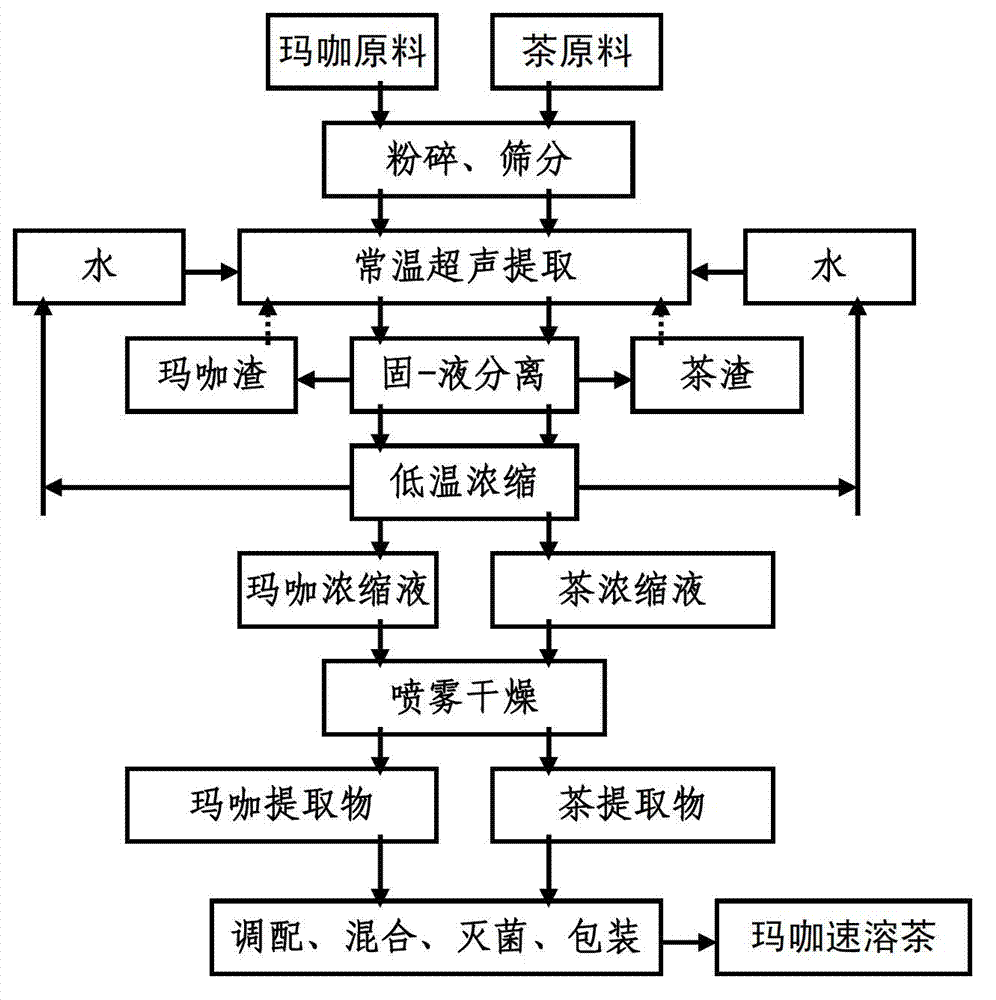

Method used

Image

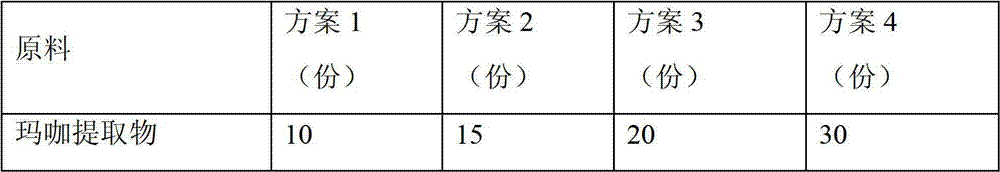

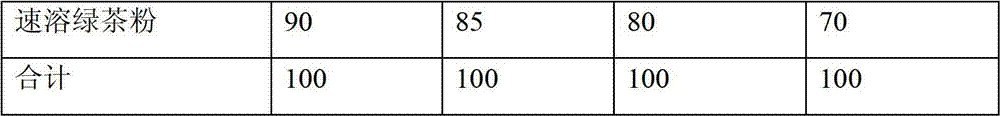

Examples

Embodiment 1

[0035] 1. Preparation of maca extract: Grind the dry root of maca to 20 mesh, use ethanol water with a mass content of 60% as the solvent, mix according to the liquid:material ratio of 10:1 (liter:kg), ultrasonically extract, and the extraction temperature 50℃, ultrasonic power 200W / cm 2 , the extraction time is 40 minutes, extraction is performed twice, solid-liquid separation, the clear liquid is vacuum concentrated at 40°C, and the concentrated liquid is spray-dried under the conditions of the inlet air temperature of 120°C and the outlet air temperature of 90°C to obtain the Maca functional extract;

[0036] 2. Preparation of instant tea powder: the tea raw material (which can be any of green tea, black tea, oolong tea, black tea, yellow tea or white tea) is crushed to 20 mesh, according to the ratio of water:material 2:1 (liter:kg ), extraction temperature 50℃, ultrasonic power 250W / cm 2 , extraction time 40 minutes, extraction 2 times, solid-liquid separation, supernata...

Embodiment 2

[0038] 1. Preparation of maca extract: crush the dry root of maca to 30 mesh, use ethanol water with a mass content of 50% as the solvent, mix according to the liquid:material ratio of 15:1 (liter:kg), ultrasonically extract, and the extraction temperature 30°C, ultrasonic power 300W / cm 2 , extraction time is 60 minutes, extraction once, solid-liquid separation, supernatant liquid concentrated in vacuum at 60°C, under the conditions of inlet air temperature 160°C and outlet air temperature 70°C, the concentrated liquid is spray-dried to obtain Maca functional extract;

[0039] 2. Preparation of instant tea powder: the tea raw material (which can be any one of green tea, black tea, oolong tea, black tea, yellow tea or white tea) is crushed to 30 mesh, according to the water:material ratio of 15:1 (liter:kg ), extraction temperature 30°C, ultrasonic power 300W / cm 2 , extraction time 60 minutes, extraction 1 time, solid-liquid separation, supernatant liquid concentrated in vacuu...

Embodiment 3

[0041] 1. Preparation of maca extract: crush the dry root of maca to 40 mesh, use ethanol water with a mass content of 30% as a solvent, mix according to a liquid:material ratio of 30:1 (liter:kg), ultrasonically extract, and extract at a temperature 20℃, ultrasonic power 150W / cm 2 , the extraction time is 30 minutes, the extraction is 3 times, solid-liquid separation, the clear liquid is concentrated in vacuum at 50°C, and the concentrated liquid is spray-dried under the conditions of an inlet air temperature of 150°C and an outlet air temperature of 60°C to obtain a functional extract of Maca;

[0042] 2. Preparation of instant tea powder: the tea raw material (which can be any one of green tea, black tea, oolong tea, black tea, yellow tea or white tea) is crushed to 40 mesh, according to the ratio of water:material 20:1 (liter:kg ), extraction temperature 20°C, ultrasonic power 200W / cm 2 , extraction time 30 minutes, extraction 3 times, solid-liquid separation, supernatant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com