Method for continuously preparing makrolon by phosgene interface polycondensation

A technology of polycarbonate and interfacial polycondensation, which is applied in the field of continuous preparation of polycarbonate by phosgene interfacial polycondensation, can solve the problems of easy fluctuation of composition, increase of material temperature, and increase of system pressure, and achieve equipment The effect of simplicity, stable product quality, and small fluctuations in molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

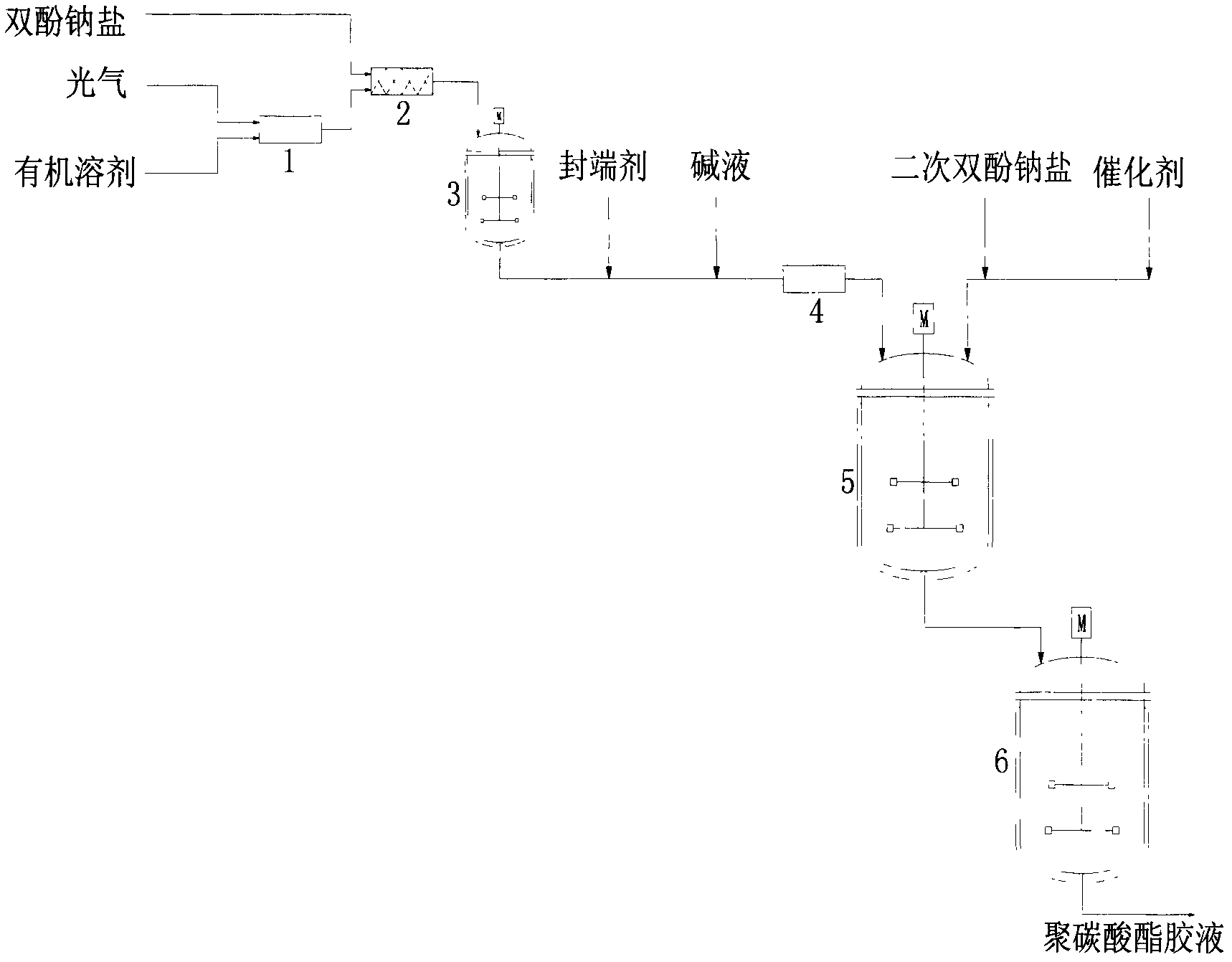

[0045] according to figure 1 The connection experimental device shown, wherein the photochemical reactor 2 is a jacketed glass pipe reactor with an inner diameter of 6mm and a filler height of 50mm, the oligomerization reactor 3 is a 500mL glass reactor with stirring and jacket, and the polycondensation reactors 5 and 6 It is a 2500mL glass reactor with stirring and jacket. Pass into bisphenol A sodium salt solution (30 ℃) to experimental device, flow rate is 30ml / min, pass into solvent dichloromethane (10 ℃), flow rate 15ml / min, pass into gaseous phosgene flow rate to be 54L / h (2.3 g / min), the oil-water two-phase enters the oligomerization reactor 3 after the residence time is less than 3s in the photochemical reactor 2, and the end-capping agent is p-tert-butylphenol, which is mixed with 5% dichloromethane solution (10 ℃), the feeding rate is 1.25mL / min, the feeding rate of 32% sodium hydroxide solution (30 ℃) is 1mL / min, the catalyst is triethylamine, it is mixed with 5% d...

Embodiment 2

[0047] according to figure 1 The connection experimental device shown, wherein photochemical reactor 2 is a jacketed glass pipe reactor with an inner diameter of 6mm and a filler height of 150mm, oligomerization reactor 3 is a 500mL glass reactor with stirring and jacket, polycondensation reactor 5, 6 It is a 2500mL glass reactor with stirring and jacket. Pass into bisphenol A sodium salt solution (30 ℃) to experimental device, flow rate is 30ml / min, pass into solvent dichloromethane (10 ℃), flow rate 15ml / min, pass into gaseous phosgene flow rate to be 54L / h (2.3 g / min), the oil-water two-phase enters the oligomerization reactor 3 after the residence time is less than 3s in the photochemical reactor 2, and the end-capping agent is p-tert-butylphenol, which is mixed with 5% dichloromethane solution (10 ℃), the feeding rate is 1.25mL / min, the feeding rate of 32% sodium hydroxide solution (30 ℃) is 1mL / min, the catalyst is triethylamine, it is mixed with 5% dichloromethane solu...

Embodiment 3

[0049] according to figure 1 The connection experimental device is shown, wherein the photochemical reactor 2 is a jacketed glass pipe reactor with an inner diameter of 6mm and a filler height of 200mm, the oligomerization reactor 3 is a 500mL glass reactor with stirring and jacket, and the polycondensation reactors 5 and 6 are It is a 2500mL glass reactor with stirring and jacket. Pass into bisphenol A sodium salt solution (30 ℃) to experimental device, flow rate is 30ml / min, pass into solvent dichloromethane (10 ℃), flow rate 15ml / min, pass into gaseous phosgene flow rate to be 54L / h (2.3 g / min), the oil-water two-phase enters the oligomerization reactor 3 after the residence time is less than 3s in the photochemical reactor 2, and the end-capping agent is p-tert-butylphenol, which is mixed with 5% dichloromethane solution (10 ℃), the feeding rate is 1.25mL / min, the feeding rate of 32% sodium hydroxide solution (30 ℃) is 1mL / min, the catalyst is triethylamine, it is mixed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com