Special microorganism organic fertilizer formula for wheat in domestic garbage fertilizer production and production process

A technology of microbial organic fertilizer and wheat, which is applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problems of unfavorable crop absorption, difficulty in meeting fertilizer standards, and high fertilizer price, so as to improve crop nutrient utilization rate, increase crop yield, and reduce pests and diseases The effect that occurs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

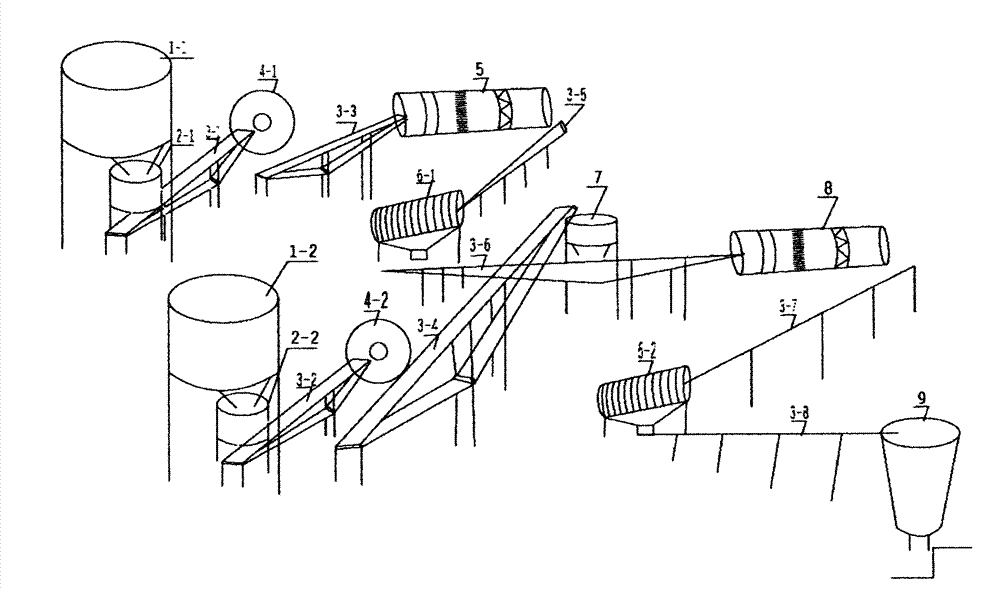

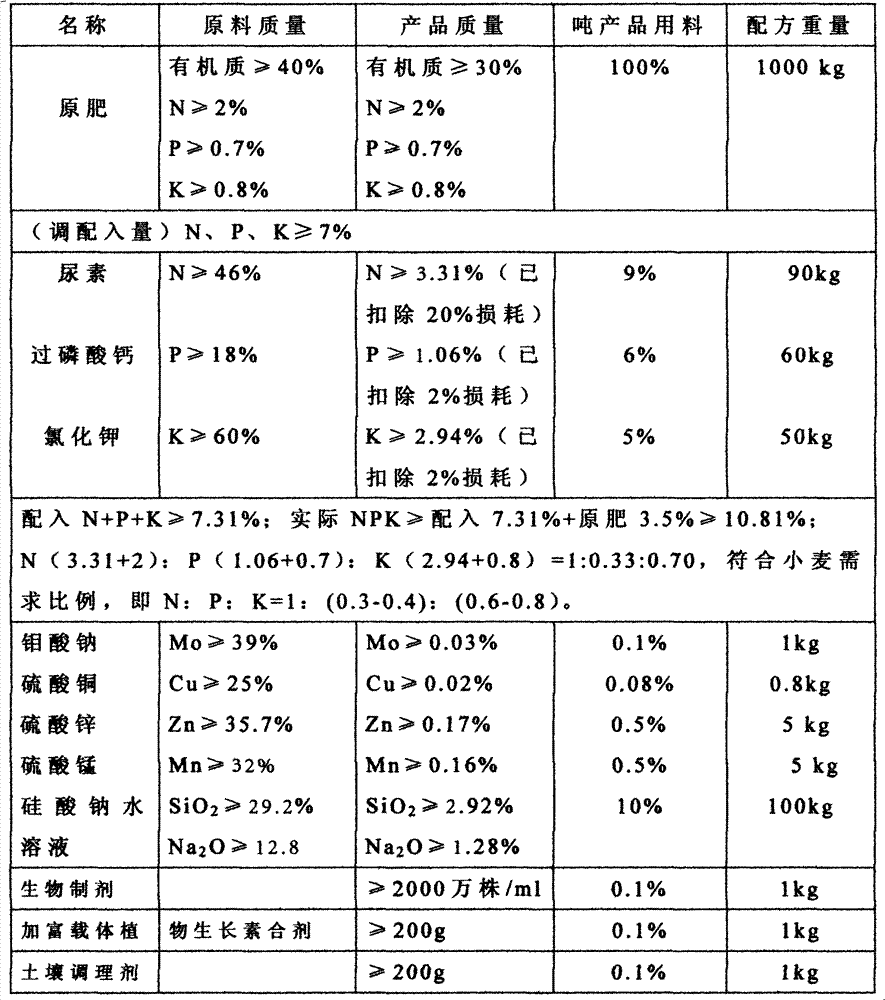

[0014] The first element coordination: Pour the raw fertilizer that is not afraid of drying damage and failure into the batching mixer 1-1 and mix in urea, superphosphate, potassium chloride, manganese sulfate and zinc sulfate heptahydrate according to the formula requirements, Mix evenly, and the agglomerate material formed by pulverizing and mixing by pulverizer 2-1 flows into conveyer belt 3-1 and sends to granulation tray 4-1 spraying (adding water and sodium silicate aqueous solution to mix by 10% of the weight of the mixing ingredients Slurry) is granulated into balls, and the granular material is sent to the dryer 5 through the conveyor belt 3-3 for drying. After rolling and drying for 25 minutes, it flows through the conveyor belt 3-5 and enters the analysis sieve 6-1. Screening (finely screen the material less than 2mm in the front part of the screen and return it for reprocessing, screen out the 2-4mm qualified granular material in the rear 1 / 3 of the screen, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com