Preparation method of cobalt-wrapped nickelous hydroxide

A technology of nickel hydroxide and cobalt hydroxide, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of irrecoverable positive electrode capacity, cobalt dissolution, incomplete conductive network, etc., to achieve uniform coating and oxide layer, high activity The effect of high material utilization and uniform and complete conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Prepare reaction solution

[0014] Prepare 1 mol / liter of cobalt sulfate solution A respectively, the weight ratio is respectively 15% potassium hydroxide solution B, 10% ammonia solution C, 30% sodium hydroxide solution D, and the preparation concentration is 0.5 mol / liter of chloride Aqueous solution E of lanthanum prepares aqueous complexing agent F, the molar ratio of each component of the aqueous complexing agent to cobalt in cobalt sulfate is ethylenediamine / Co=0.4, oxalic acid / Co=0.1.

[0015] Reaction to obtain nickel hydroxide coated with cobalt hydroxide

[0016] Add 150 g / L of spherical nickel hydroxide and pure water mixture into the reactor, adjust the pH of the reaction solution to 9 with Solution B, adjust the ammonia concentration in the reaction solution with Solution C to be 15 g / L, and control the temperature to 50°C.

[0017] Add solution A, solution B, solution C, solution E and solution F to the reactor simultaneously and continuously for coating ...

Embodiment 1

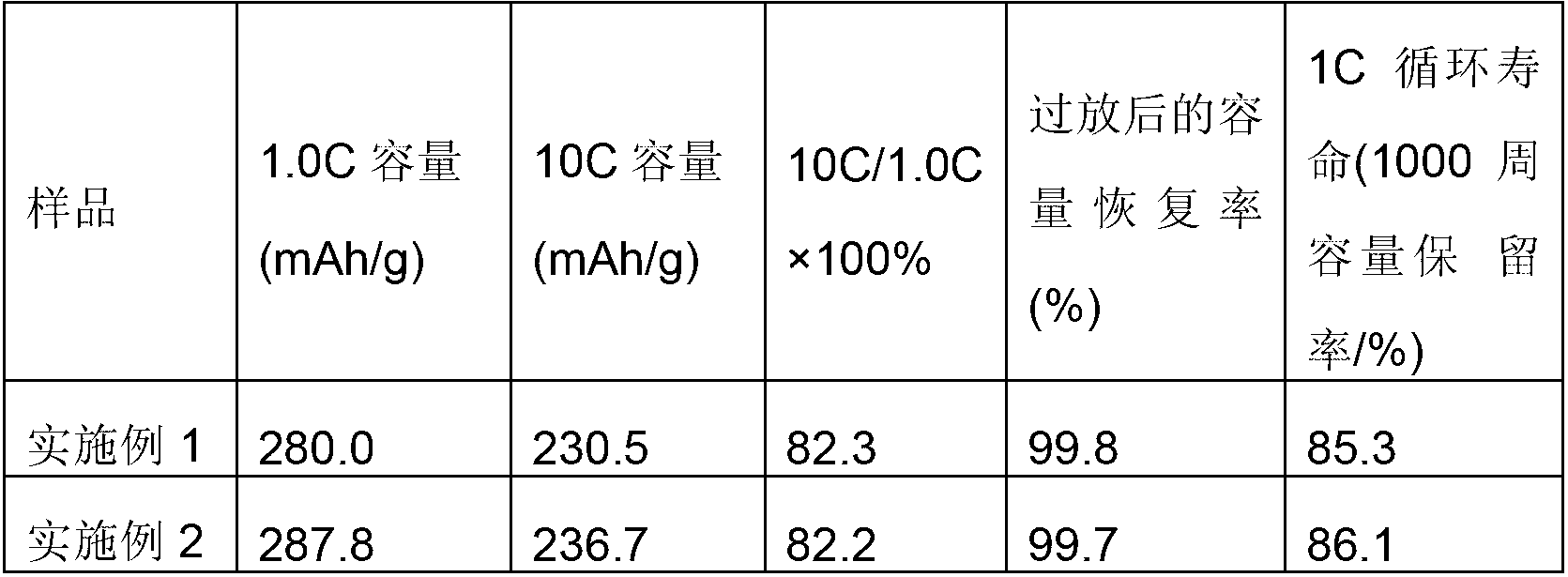

[0022] The powder impedance of the nickel hydroxide active material A obtained in Example 1 is 0.8 Ω·cm, and the average valence state of cobalt coated with cobalt on the surface is 3.08 as measured by the iodometric method. The electrical performance test results are shown in Table 1.

Embodiment 2

[0024] Prepare reaction solution

[0025] Prepare 1 mol / liter of cobalt sulfate solution A respectively, the weight ratio is respectively 20% potassium hydroxide solution B, 15% ammonia solution C, 50% sodium hydroxide solution D, and the preparation concentration is 0.8 mol / liter of chloride Aqueous solution E of yttrium prepares aqueous complexing agent F, the molar ratio of each component of the aqueous complexing agent to cobalt in cobalt sulfate is ethylenediamine / Co=0.6, oxalic acid / Co=0.3.

[0026] Reaction to obtain nickel hydroxide coated with cobalt hydroxide

[0027] Add 240 g / L of spherical nickel hydroxide and pure water mixture into the reactor, adjust the pH of the reaction solution to 11 with Solution B, adjust the ammonia concentration in the reaction solution with Solution C to be 20 g / L, and control the temperature to 65°C.

[0028] Add solution A, solution B, solution C, solution E and solution F to the reactor simultaneously and continuously for coating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com