Mesoporous cerium zirconium solid solution composite oxide nano material and preparation method thereof

A composite oxide, cerium zirconium solid solution technology, applied in chemical instruments and methods, zirconia, nanotechnology and other directions, can solve the problem of poor thermal stability of mesoporous cerium zirconium solid solution composite oxide, irregular pore size distribution, small specific surface area, etc. problem, to achieve the effect of simple and controllable synthesis route, low cost and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

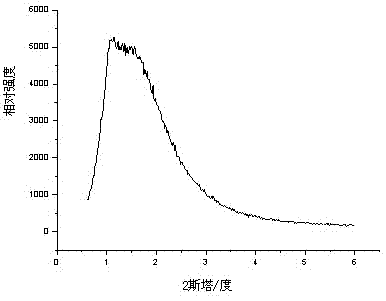

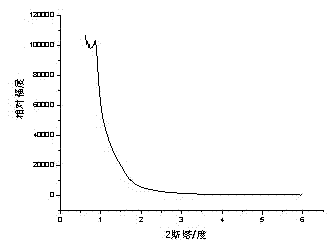

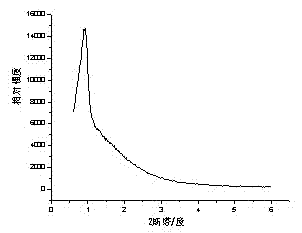

Image

Examples

Embodiment 1

[0051] A method for preparing a mesoporous cerium-zirconium solid solution composite oxide nanomaterial, comprising the following steps:

[0052] (1), add 0.5g of EO 106 PO 70 EO 106 Disperse in 5g of ethanol and stir at room temperature for 5min, then add 0.085g of zirconium oxychloride (ZrOCl 2 ·8H 2 O, molecular weight: 322.25) and 0.115g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O, molecular weight: 434.25), stirred at room temperature for 5 minutes, then added 0.05g tetraethyl orthosilicate and 0.25g phenolic resin in turn, and continued to stir at room temperature for 20 minutes until a homogeneous transparent solution was formed;

[0053] Put the homogeneous transparent solution obtained above into a crystallization dish and put it in a fume hood overnight, then put it into a blast drying oven, control the temperature at 50°C, and take 24 hours to obtain the organic / inorganic cerium-zirconium composite oxide. dry film;

[0054] (2) Put the dry film of organic / inorganic ...

Embodiment 2

[0063] A method for preparing a mesoporous cerium-zirconium solid solution composite oxide nanomaterial, comprising the following steps:

[0064] (1), add 0.25g of EO 20 PO 70 EO 20 Disperse in 25g of deionized water and stir at room temperature for 5min, then add 0.1g of zirconium tetrachloride (ZrCl 4 Molecular weight: 233.2) and 0.0193 g ceric sulfate (Ce(SO 4 ) 2 .4H 2 O molecular weight: 404.284), stirred at room temperature for 5 minutes, then added 2g tetramethyl orthosilicate and 12.5g sucrose in turn, stirred at room temperature for 20 minutes until a homogeneous transparent solution was formed;

[0065] Put the homogeneous transparent solution obtained above into a crystallization dish, put it in a fume hood overnight, and then put it into a blast drying oven to control the temperature at 150°C for 24 hours to obtain organic / inorganic cerium-zirconium solid solution composite oxide. dry film;

[0066] (2) Put the dry film of organic / inorganic cerium-zirconium...

Embodiment 3

[0071] A method for preparing a mesoporous cerium-zirconium solid solution composite oxide nanomaterial, comprising the following steps:

[0072] (1), add 0.25g of EO 132 PO 60 EO 132 Disperse in 6g of methanol, stir at room temperature for 5min, then add 0.0153g of zirconium nitrate (Zr(NO 3 ) 4 .5H 2 O molecular weight: 339.24) and 0.1g cerous chloride (CeCl 3 , molecular weight: 246.48), stirred at room temperature for 5 minutes, then added 0.05g tetrapropyl orthosilicate and 1.25g furfuryl alcohol resin in turn, stirred at room temperature for 30 minutes until a homogeneous transparent solution was formed;

[0073] Put the homogeneous transparent solution obtained above into a crystallization dish, put it in a fume hood overnight, then put it into a blast drying oven, control the temperature at 60°C, and take 24 hours to obtain an organic / inorganic zirconia solid solution compound Dry film of objects;

[0074] (2) Put the dry film of the organic / inorganic cerium-zir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com