Polyimides containing ditrifluoromethyl group and unsymmetrical structure and preparation method thereof

A bis-trifluoromethyl, polyimide technology, applied in the field of polyimide preparation, can solve the problems of polyimide insolubility, poor color optical transparency, etc., and achieve good film-forming properties, excellent mechanical properties, The effect of excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

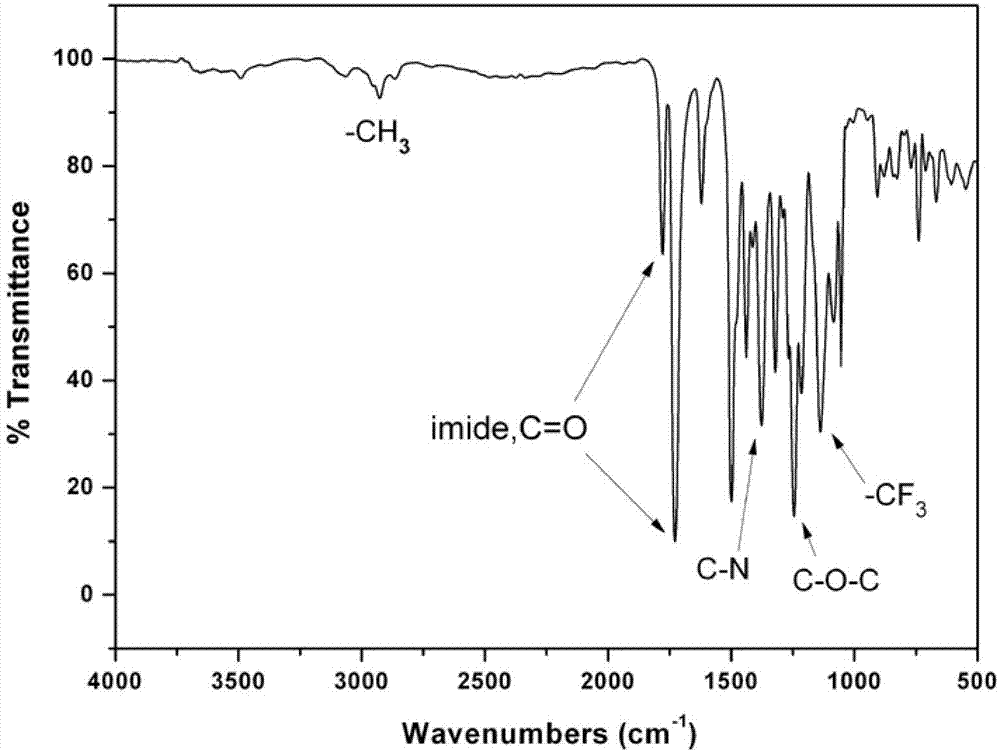

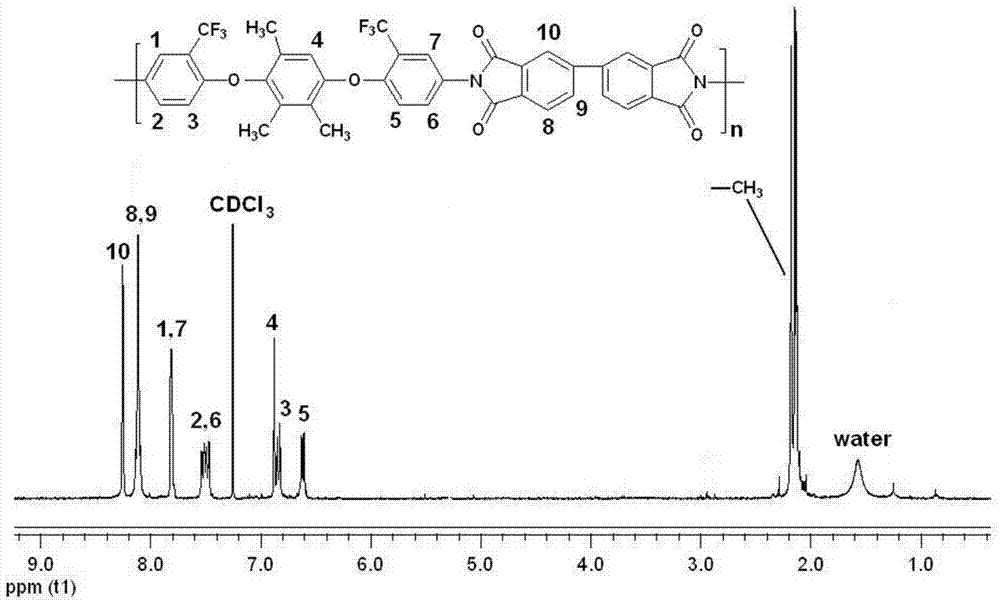

Embodiment 1

[0025] Add 1.5mmol bistrifluoromethyl-substituted asymmetric aromatic diamine monomer and 1.5mmol biphenyltetraacid dianhydride to a 50ml three-necked round-bottomed flask that is dry and nitrogen-gassed, and then add 15ml m-cresol solvent (system The solid content is 5-20%), then add about 0.7g of isoquinoline as a catalyst, raise the temperature of the reaction system to 100°C for 5 hours, then heat up to 200°C for about 6 hours, and pour the polymer solution after cooling to 120°C into 300ml of methanol or ethanol, and the precipitate was collected by filtration, washed twice with boiling water, and vacuum-dried at 150°C to obtain a white fibrous polyimide.

Embodiment 2

[0027] In a dry 50ml three-necked round-bottomed flask with nitrogen, add 1.5mmol containing bistrifluoromethyl substituted asymmetric aromatic diamine monomer and 1.5mmol diphenyl ether tetraacid dianhydride, then add 10ml m-cresol solvent ( The solid content of the system is 5-20%), then add about 0.4g of isoquinoline as a catalyst, raise the temperature of the reaction system to 140°C for 2 hours, then raise the temperature to 190°C for about 20h, cool to 120°C and dissolve the polymer solution Pour it into 300ml of methanol or ethanol, collect the precipitate by filtration, wash it twice with boiling water, and dry it in vacuum at 150°C to obtain a white fibrous polyimide.

Embodiment 3

[0029] Preparation of 1,4-bis(4-amino-2-trifluoromethylphenoxy)-2,3,5-trimethylbenzene:

[0030] ①Under nitrogen protection, add 15.22g (0.1mol) 2,3,5-trimethylhydroquinone and 45.11g (0.2mol) 2-chloro-5-nitrobenzotrifluoride into a 500ml three-necked flask Add 28.98g (0.21mol) of potassium carbonate and 130ml of N,N-dimethylformamide respectively, react at 120°C for 12h, pour the product into 1000ml of methanol / water (1:1) and fully stir, precipitate and filter. The product was washed repeatedly with hot water, and further recrystallized with N,N-dimethylformamide / methanol (3:2) mixed solvent to obtain a light yellow fluorine-containing dinitro compound: 1,4-bis(4-nitro- 2-trifluoromethylphenoxy)-2,3,5-trimethylbenzene, the yield is 85%, and the melting point is 256-257°C. 1 H NMR (DMSO-d 6 ,400MHz) δ: 8.64(d,J=2.8Hz,1H),8.62(d,J=2.8Hz,1H),8.32(dd,J 1 =2.8Hz,J 2 =9.2Hz,1H),8.30(dd,J 1 =2.8Hz,J 2 =9.2Hz,1H),6.91(s,1H),6.80(d,J=9.2Hz,1H),6.62(d,J=9.2Hz,1H),2.13(s,3H),2.11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com