Flexible organic/polymer solar cell and preparation method thereof

A solar cell and polymer technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as difficulty in realizing high-efficiency flexible organic polymer solar cells, unfavorable large-scale industrial production, etc., and achieve the effect of improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

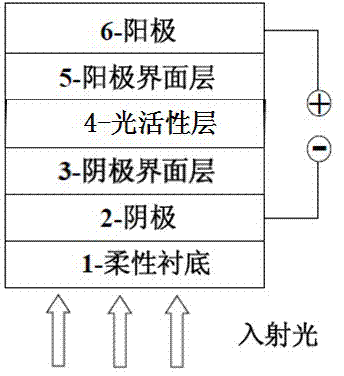

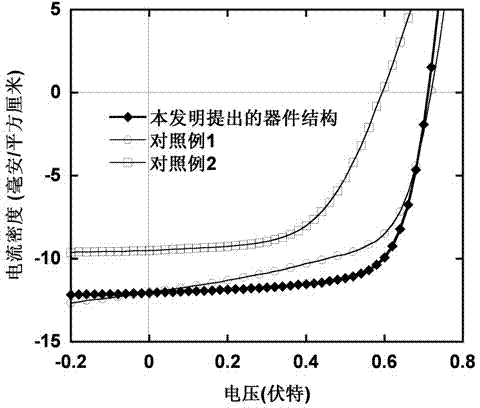

[0061] select figure 1 In the flexible organic / polymer (polymer) solar cell device structure shown, polyethylene terephthalate is selected as the flexible substrate, and poly[9,9-dioctylfluorene-9,9-bis( N,N-Dimethylaminopropyl)fluorene] (PFN) as the cathode interface layer, benzodithiophene derivatives (PTB7) as polymer electron donor materials, carbon 70 derivatives-[6,6]-benzene Base-C71-butyric acid methyl ester (PC 71 BM) is the electron acceptor material, and the device structure is prepared as PET / ITO / PFN / PTB7:PC 71 BM / MoO 3 / Al flexible organic / polymer (polymer) solar cells, and their volt-ampere characteristic curves (such as figure 2 shown). A conventional flexible device based on a low temperature process was also prepared in the experiment as a control example. Among them, the structure of Comparative Example 1 is: PET / ITO / PEDOT:PSS / PTB7:PC 71 BM / Al, the structure of Comparative Example 2 is PET / ITO / PTB7:PC 71 BM / MoO 3 / Al.

[0062] according to figure ...

Embodiment 2

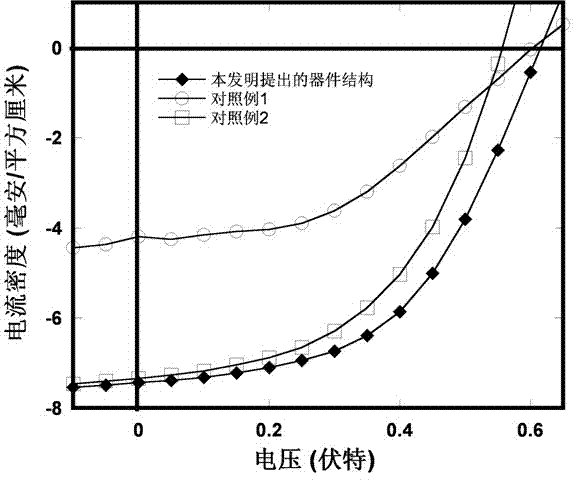

[0067] Repeat Example 1, select poly 3-hexylthiophene (P3HT) as the electron donor material in the photoactive layer 4, [6,6]-phenyl-C 61-butyric acid methyl ester (PC 61 BM) as the electron acceptor material in the photoactive layer 4, other conditions remain unchanged, and the device structure is prepared as the device structure is PET / ITO / PFN / P3HT:PC 61 BM / MoO 3 / Al flexible organic / polymer (polymer) solar cells. A conventional flexible device based on a low temperature process was also prepared in the experiment as a control example. Wherein, the structure of comparative example 1 is: PET / ITO / PEDOT:PSS / P3HT:PC 61 BM / Al, the structure of Comparative Example 2 is PET / ITO / P3HT:PC 61 BM / MoO 3 / Al). The volt-ampere characteristic curves of various devices were measured under AM 1.5 G simulated sunlight with an irradiance of 1000 watts / square meter, such as image 3 Experiment shown. The performance results of the devices are listed in Table 3.

[0068] It can be seen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com