Human hair keratin shape righting material with adjustable and controllable mechanical property as well as preparation method thereof

A kind of keratin and autologous technology, applied in the direction of human tubular structure devices, blood vessels, muscles, etc., can solve the problems of increasing pain for patients, achieve the goal of avoiding pain, ensuring biocompatibility and safety of use, and improving elasticity and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Cut the washed human hair into 3-5mm long fiber segments, and immerse it in a solution of 250ml potassium bisulfite and urea with a solid-liquid ratio of 3g / 100ml, wherein the solution is prepared by adding sodium metabisulfite to 7M Obtained from urea aqueous solution, the mass concentration of potassium bisulfite is 8%, the mixture is stirred at 60° C. for 5 h, and the rotation speed of the stirrer is 300 r / min. After filtering through an 80-mesh sieve, centrifuge at 4000rpm for 0.4h and take the supernatant. Under the condition of nitrogen protection, the filter module is used to quickly desalinate and remove low molecular weight salts in the solution, and then concentrate to obtain a keratin solution with a concentration of 3% by mass.

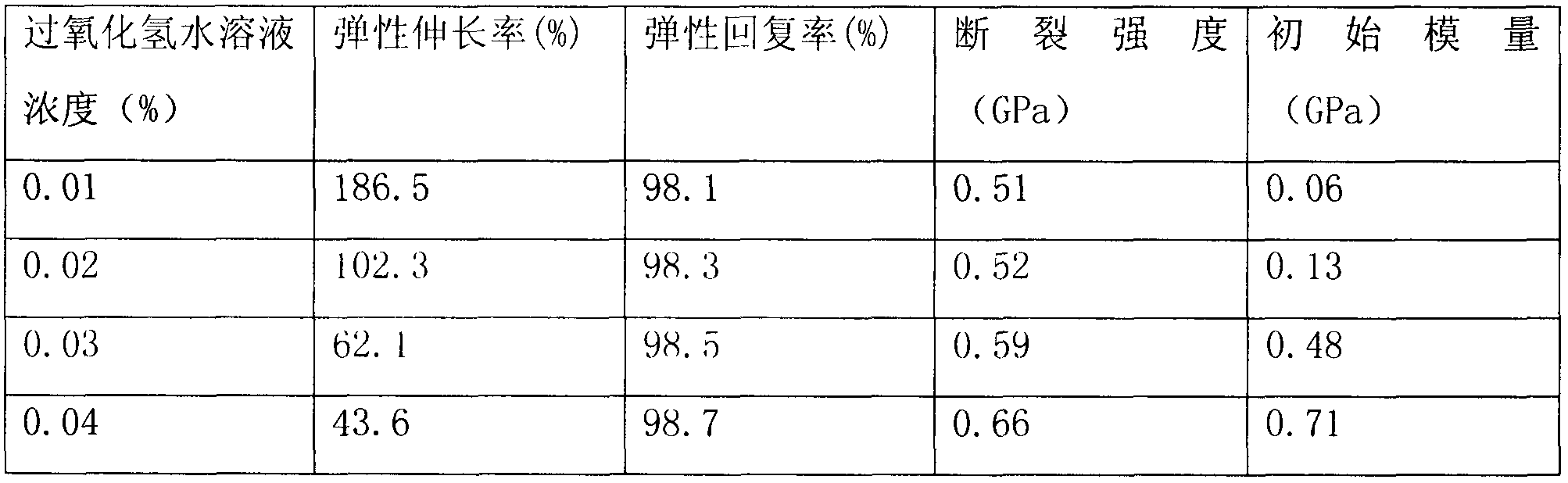

[0026] Slowly drop 0.01% aqueous hydrogen peroxide solution into the pure keratin solution at a mass percentage of 1:100, then cast the keratin solution into a sheet mold with a thickness of 1 mm, and solidify at a temperature of 50°...

Embodiment 2

[0028] Cut the washed human hair into 3-5mm long fiber segments, and immerse it in a solution of 250ml sodium metabisulfite and urea with a solid-liquid ratio of 1g / 100ml, wherein the solution is obtained by adding sodium metabisulfite to a 6M aqueous urea solution The mass concentration of sodium metabisulfite was 7%, and the mixture was stirred at 90° C. for 2 h, and the speed of the stirrer was 200 r / min. After filtering through a 120-mesh sieve, centrifuge at 7000rpm for 0.2h and take the supernatant. Under the condition of nitrogen protection, the filter module is used to quickly desalinate and remove low molecular weight salts in the solution, and then concentrate to obtain a keratin solution with a concentration of 2% by mass.

[0029] Slowly drop 0.02% aqueous hydrogen peroxide solution into the pure keratin solution at a ratio of 1:100 by mass, and then cast the keratin solution into a micro-pipe mold that simulates the size of blood vessels, at a temperature of 40°C ...

Embodiment 3

[0031]Cut the cleaned rat hair into 3-5mm long fiber segments, and immerse it in the solution of 250ml potassium sulfite and thiourea with a solid-liquid ratio of 4g / 100ml, wherein the solution is obtained by adding potassium sulfite to It was obtained from a 10M thiourea aqueous solution, the mass concentration of potassium sulfite was 12%, and the mixture was stirred at 50° C. for 4 hours, and the speed of the stirrer was 100 r / min. After filtering through a 100-mesh sieve, centrifuge at 3000rpm for 1 hour and take the supernatant. Under the condition of nitrogen protection, the filter module is used to quickly desalinate and remove low molecular weight salts in the solution, and then concentrate to obtain a keratin solution with a concentration of 5% by mass.

[0032] Aqueous hydrogen peroxide solution with a concentration of 0.04% is slowly dropped into the pure keratin solution at a mass percentage of 1:100, and then the keratin solution is cast in a long and thin mold wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com