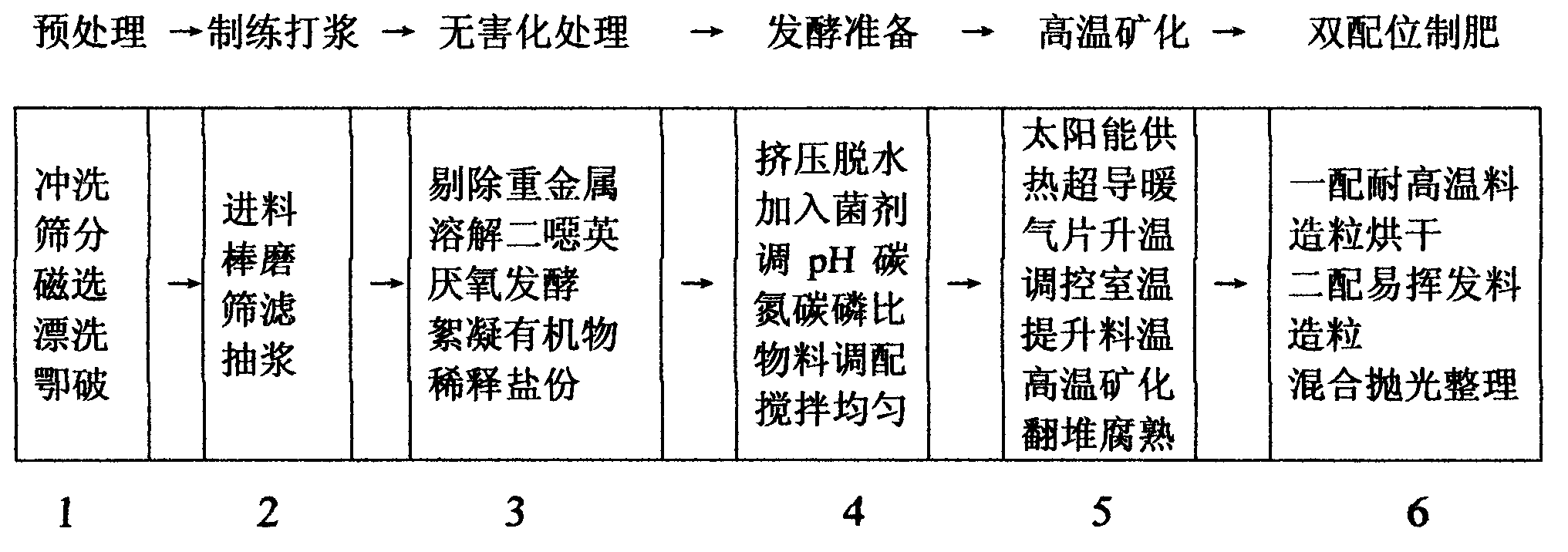

Method for preparing fertilizer by mineralized fermentation through rejecting heavy metal in kitchen waste and decomposing dioxin

A technology for kitchen waste and heavy metals, applied in organic fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of inability and incompleteness of composting, so as to reduce heavy pressure, improve yield and quality, and protect and improve ecology. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

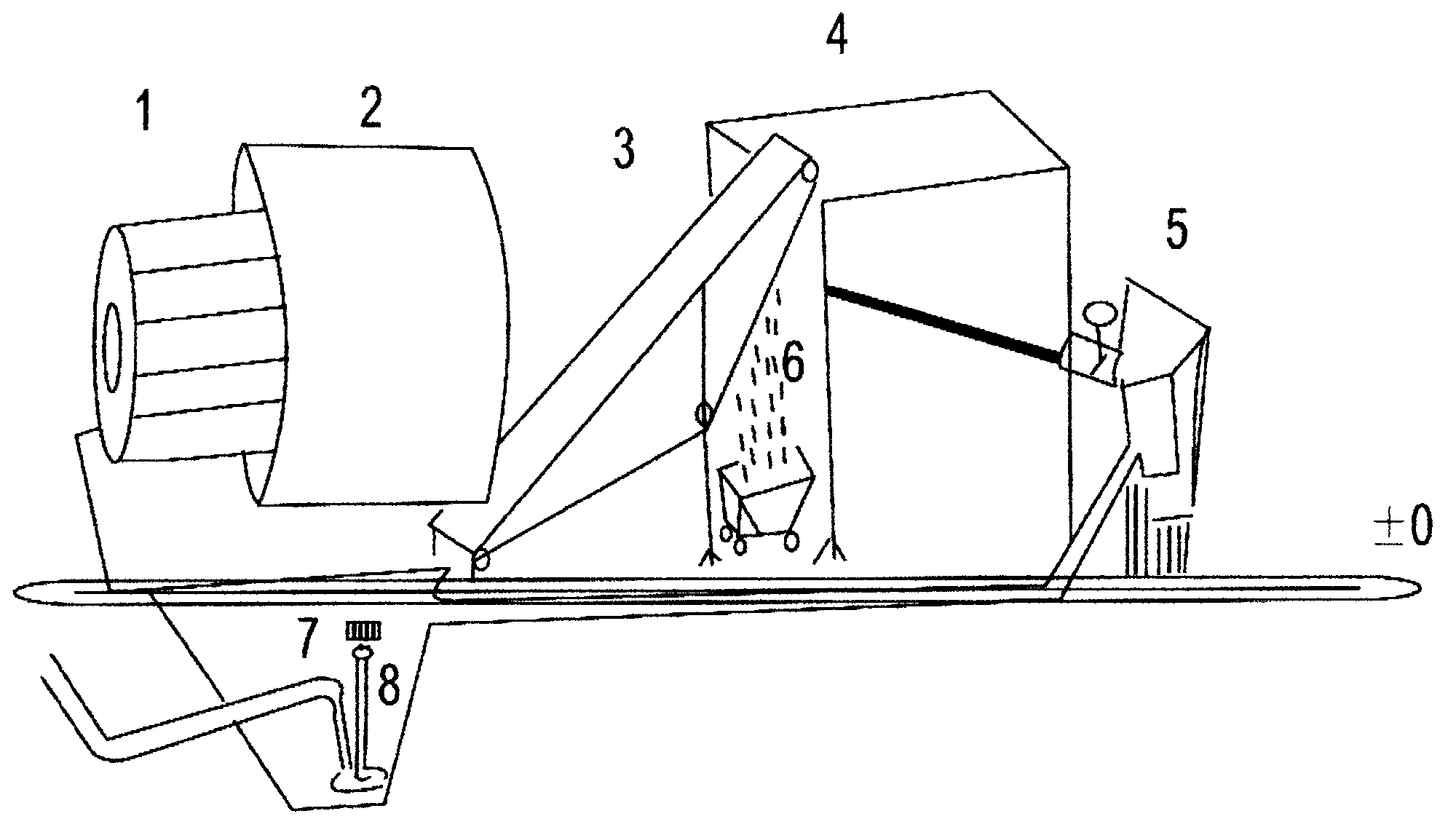

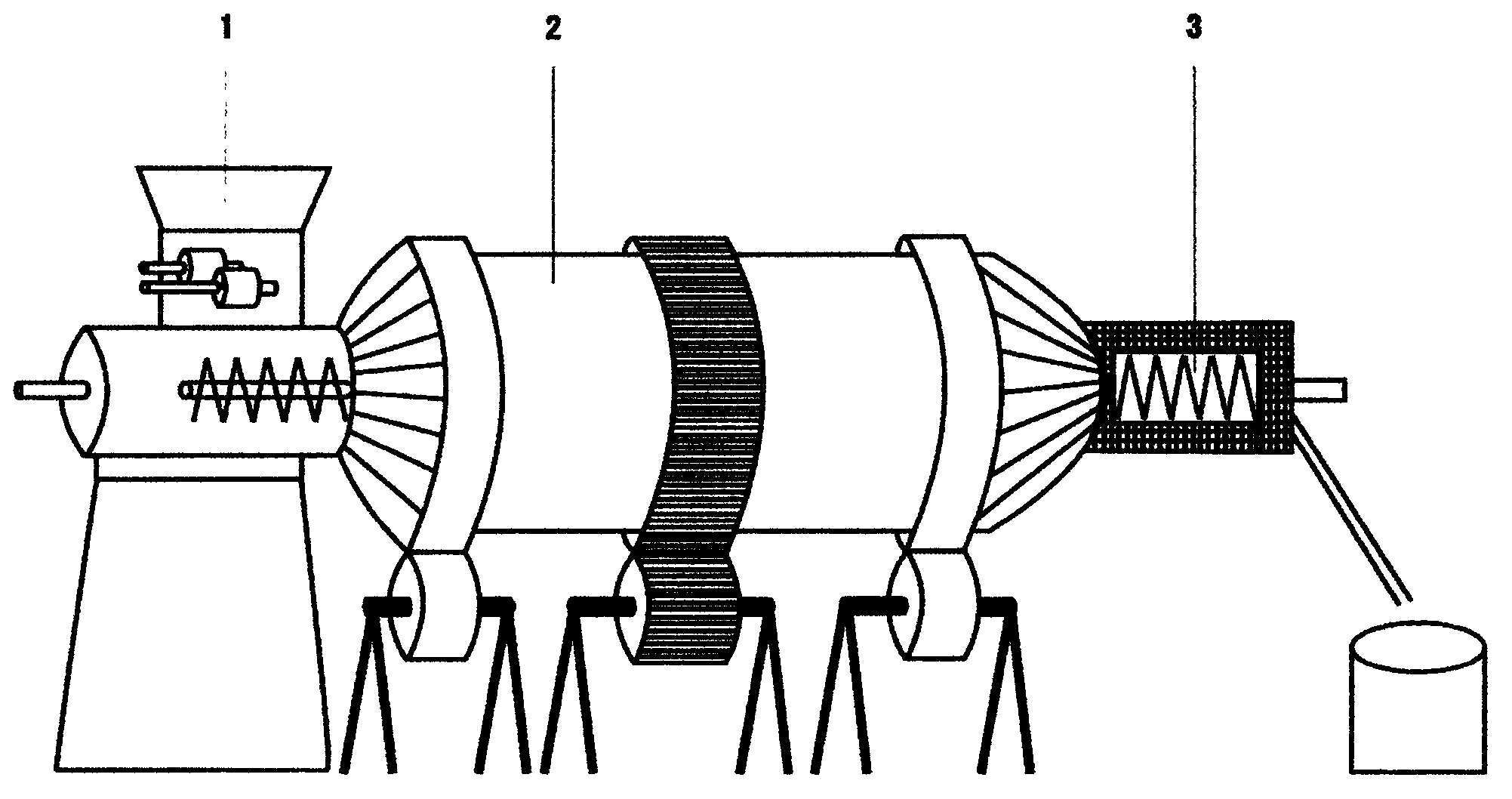

Method used

Image

Examples

Embodiment

[0036] Example: In this example, the special microbial organic fertilizer for corn is carried out in a double-coordinated bio-organic fertilizer production line, using a large-scale mixing and crushing unit with a volume of 1000Kg, using 194 tons of food waste and 48 tons of fermented raw fertilizer produced by ingredients, and adding in proportion : 4.8 tons of urea, 3.36 tons of calcium magnesium phosphate fertilizer, 2.4 tons of potassium chloride, 0.96 tons of manganese sulfate, 0.48 tons of zinc sulfate heptahydrate, 2.4 tons of sodium silicate aqueous solution, 48Kg of sodium molybdate, 38.4Kg of copper sulfate, 48Kg of biological agents, Add 48Kg of carrier auxin mixture and 48Kg of soil conditioner. The amount of raw fertilizer is 500Kg at a time. The operation process is as follows:

[0037] Preparation of sodium silicate slurry: watering amount=(raw fertilizer 48t+urea 4.8t+calcium magnesium phosphate fertilizer 3.36t+potassium chloride 2.4t+manganese sulfate 0.96t+...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com