Etherified-starch-grafted-copolymer super absorbent resin and preparation method thereof

A technology of super absorbent resin and graft copolymer is applied in the field of preparation of novel functional polymer materials to achieve the effects of convenient storage and transportation, simple preparation process and improved salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

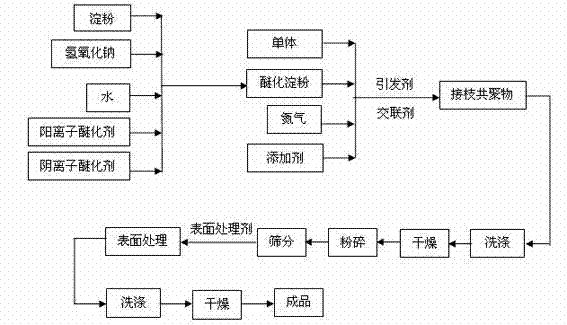

Method used

Image

Examples

Embodiment 1

[0041] 1. The raw material components used in this embodiment are as follows:

[0042] Starch (corn starch): 200 kg

[0043] Cationic etherification agent (3-chloro-2-hydroxypropyl-trimethylammonium chloride) 5 kg

[0044] Anionic etherification agent (chloroacetic acid) 5 kg

[0045] Monomer (acrylic acid / acrylamide, mass ratio 1:1): 186 kg

[0046] Additive (ascorbic acid): 0.2 kg

[0047] Initiator (potassium persulfate): 5 kg

[0048] Cross-linking agent (polypropylene glycol glycidyl ether): 0.8 kg

[0049] Surface treatment agent (sorbitol / magnesium oxide, mass ratio 3:1): 10 kg

[0050] Alkaline conditioner (sodium hydroxide): 30 kg

[0051] Water: 558 kg

[0052] 2. The preparation process steps and process parameters of this embodiment:

[0053] (1) Preparation of etherified starch: 200 kg of cornstarch, 374 kg of water, and 9.2 kg of sodium hydroxide solution with a mass fraction of 20% were added to the reactor, the pH of the system was about 10, and 25 kg o...

Embodiment 2

[0057] 1. The raw material components used in this embodiment are as follows:

[0058] Starch (sweet potato starch): 150 kg

[0059] Cationic etherification agent (N-(2,3-epoxypropyl)diethylamine) 3 kg

[0060] Anionic etherification agent (chloroacetic acid) 8 kg

[0061] Monomer (acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid, mass ratio 3:1): 200 kg

[0062] Additive (sodium formate): 1 kg

[0063] Initiator (ammonium persulfate): 10 kg

[0064] Cross-linking agent (N,N-methylenebisacrylamide): 0.8 kg

[0065] Surface treatment agent (glycerol / silicon dioxide, mass ratio 4:1): 8 kg

[0066] Alkaline conditioner (potassium hydroxide): 50 kg

[0067] Water: 569.2 kg

[0068] 2. The preparation process steps and process parameters of this embodiment:

[0069] (1) Preparation of etherified starch: Add 150 kg of sweet potato starch, 278 kg of water, and 15 kg of potassium hydroxide solution with a mass fraction of 20% into the reactor. N-(2,3-epoxypropyl)diethyl...

Embodiment 3

[0073] 1. The raw material components used in this embodiment are as follows:

[0074] Starch (corn starch): 100 kg

[0075] Cationic etherification agent (N-(2,3-epoxychloropropyl)trimethylammonium chloride) 3 kg

[0076] Anionic etherification agent (chloroacetic acid) 4 kg

[0077] Monomer (ethyl acrylate / acrylamide, mass ratio 1:1): 400 kg

[0078] Additive (sodium D-gluconate): 1 kg

[0079] Initiator (ammonium persulfate): 30 kg

[0080] Cross-linking agent (polyethylene glycol): 3 kg

[0081] Surface treatment agent (polyethylene glycol / alumina, the mass ratio is 3:1): 12 kg

[0082] Alkaline conditioner (lithium hydroxide): 10 kg

[0083] Water: 437 kg

[0084] 2. The preparation process steps and process parameters of this embodiment:

[0085] (1) Preparation of etherified starch: Add 100 kg of cornstarch, 233 kg of water, and 8 kg of lithium hydroxide solution with a mass fraction of 20% to the reactor. The pH of the system is about 11.5. N-(2,3-epoxychlorop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com