Etherified-starch-grafted-copolymer super absorbent resin and preparation method thereof

A technology of superabsorbent resin and graft copolymer, which is applied in the field of preparation of new functional polymer materials to achieve mild reaction, improved salt resistance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

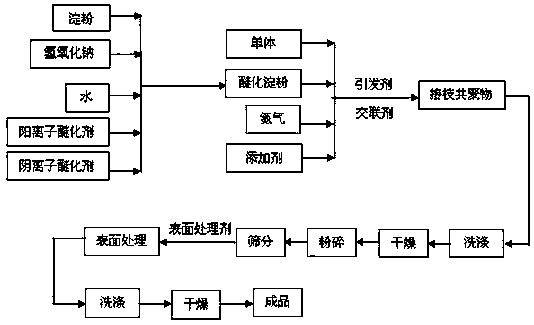

Method used

Image

Examples

Embodiment 1

[0041] 1. The raw material components used in this embodiment are as follows:

[0042] Starch (corn starch): 200 kg

[0043] Cationic etherification agent (3-chloro-2-hydroxypropyl-trimethylammonium chloride) 5 kg

[0044] Anionic etherification agent (chloroacetic acid) 5 kg

[0045] Monomer (acrylic acid / acrylamide, mass ratio 1:1): 186 kg

[0046] Additive (ascorbic acid): 0.2 kg

[0047] Initiator (potassium persulfate): 5 kg

[0048] Cross-linking agent (polypropylene glycol glycidyl ether): 0.8 kg

[0049] Surface treatment agent (sorbitol / magnesium oxide, mass ratio 3:1): 10 kg

[0050] Alkaline conditioner (sodium hydroxide): 30 kg

[0051] Water: 558 kg

[0052] 2. The preparation process steps and process parameters of this embodiment:

[0053] (1) Preparation of etherified starch: 200 kg of cornstarch, 374 kg of water, and 9.2 kg of sodium hydroxide solution with a mass fraction of 20% were added to the reactor, the pH of the system was about 10, and 25 kg o...

Embodiment 2

[0057] 1. The raw material components used in this embodiment are as follows:

[0058] Starch (sweet potato starch): 150 kg

[0059] Cationic etherification agent (N-(2,3-epoxypropyl)diethylamine) 3 kg

[0060] Anionic etherification agent (chloroacetic acid) 8 kg

[0061] Monomer (acrylic acid / 2-acrylamide-2-methylpropanesulfonic acid, mass ratio 3:1): 200 kg

[0062] Additive (sodium formate): 1 kg

[0063] Initiator (ammonium persulfate): 10 kg

[0064] Cross-linking agent (N,N-methylenebisacrylamide): 0.8 kg

[0065] Surface treatment agent (glycerol / silicon dioxide, mass ratio 4:1): 8 kg

[0066] Alkaline conditioner (potassium hydroxide): 50 kg

[0067] Water: 569.2 kg

[0068] 2. The preparation process steps and process parameters of this embodiment:

[0069] (1) Preparation of etherified starch: Add 150 kg of sweet potato starch, 278 kg of water, and 15 kg of potassium hydroxide solution with a mass fraction of 20% into the reactor. N-(2,3-epoxypropyl)diethyl...

Embodiment 3

[0073] 1. The raw material components used in this embodiment are as follows:

[0074] Starch (corn starch): 100 kg

[0075] Cationic etherification agent (N-(2,3-epoxychloropropyl)trimethylammonium chloride) 3 kg

[0076] Anionic etherification agent (chloroacetic acid) 4 kg

[0077] Monomer (ethyl acrylate / acrylamide, mass ratio 1:1): 400 kg

[0078] Additive (sodium D-gluconate): 1 kg

[0079] Initiator (ammonium persulfate): 30 kg

[0080] Cross-linking agent (polyethylene glycol): 3 kg

[0081] Surface treatment agent (polyethylene glycol / alumina, the mass ratio is 3:1): 12 kg

[0082] Alkaline conditioner (lithium hydroxide): 10 kg

[0083] Water: 437 kg

[0084] 2. The preparation process steps and process parameters of this embodiment:

[0085] (1) Preparation of etherified starch: Add 100 kg of cornstarch, 233 kg of water, and 8 kg of lithium hydroxide solution with a mass fraction of 20% to the reactor. The pH of the system is about 11.5. N-(2,3-epoxychlorop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com