Method for producing anhydrous Na2SO3 by using alkali-containing waste mother liquor

A technology of waste mother liquor and na2so3, applied in the field of production of anhydrous sodium sulfite, can solve the problems of unsolved waste alkali water pollution, short production process, low cost, etc., and achieves high sales added value, small investment and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

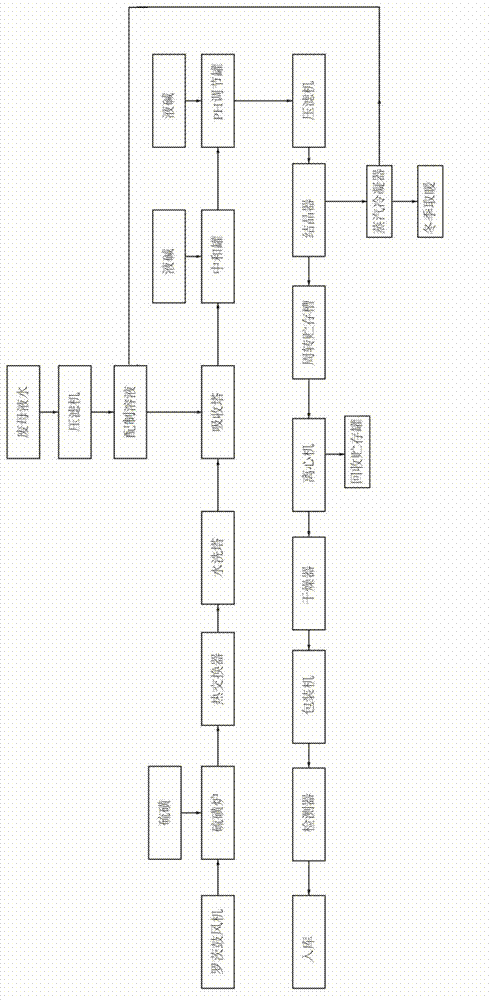

Image

Examples

Embodiment 1

[0034] The main components of the heavy soda ash waste liquid produced by the soda ash factory used in the present invention are: sodium chloride: 60-75 g L -1 , sodium carbonate: 230-260 g·L -1 . The method and technological process of producing anhydrous sodium sulfite are as follows:

[0035] (1) Initial treatment of heavy soda ash waste mother liquor: use a filter press to filter, give a pressure of 100-120kpa, filter out impurities in heavy soda ash waste mother liquor, and then prepare a concentration of 18-22 degrees Baume The solution;

[0036](2) Generation of sulfur dioxide and water washing: Air is blown into the sulfur furnace by a Roots blower, and the sulfur is burned in the sulfur furnace. Sulfur is oxidized and then enters the absorption tower. The liquid obtained after washing sulfur dioxide with water, after filtration, the obtained filtrate is added to magnesium oxide to form magnesium sulfate cold crystallization, which is used as a flocculant for indus...

Embodiment 2

[0046] The specific method, process flow and recycling approach of this embodiment are basically the same as those in Example 1, the difference being step (4), step (5), and step (7), as follows:

[0047] (4) Neutralization: pump the mixed mother liquor of sodium sulfite and sodium bisulfite into the neutralization tank, add ion-exchange membrane liquid caustic soda at 100°C-120°C to neutralize until the pH value is 8, and make the mixed mother liquor completely generate sodium sulfite;

[0048] (5) Adjust the pH value: put the neutralized sodium sulfite and sodium bisulfite mixed mother liquor into the pH adjustment tank, add liquid alkali to adjust the pH value to 12;

[0049] (7) Evaporate the mother liquor until the mass fraction of crystals is 38-39%, and when the crystallization temperature is 120°C, keep it for 3-4 hours to obtain sodium sulfite crystals;

[0050] After testing, the high-grade anhydrous sodium sulfite produced accounted for 20%, and the first-grade anhy...

Embodiment 3

[0052] The specific method and process flow of this embodiment are basically the same as those of Embodiment 1, the difference lies in step (4) and step (5), as follows:

[0053] Step (4) and step (5) are combined into one step: pump the mixed mother liquor of sodium sulfite and sodium bisulfite into the neutralization tank, and add ion membrane liquid caustic soda at 100°C-120°C until the pH value is greater than 12;

[0054] After testing, the anhydrous sodium sulfite produced is all qualified.

[0055] The above-mentioned methods and technological process are similar in the treatment of alkali-containing waste liquid or waste gas desulfurization. It is used in the purification of waste lye produced in the production process of other chemical products, and is also applicable to the desulfurization of sulfur dioxide-containing gas discharged from high-sulfur coal and pyrite. The technological process and method steps of the purification treatment are basically the same, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com