Acinetobacter lwoffii and method for preparing textile fibers by using same

A technology of Acinetobacter lwedenii and textile fibers, which is applied in the field of textile fibers, can solve the problems that chemical preparations cannot be separated from waste liquid, cannot achieve effective recycling and reuse, and cannot be reused for organic matter, and saves coal consumption. Quantity, low production cost, and the effect of improving purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The configuration of embodiment 1 bacterial liquid

[0026] The biological bacteria adopted in the present invention have been preserved on April 6, 2012 in the General Microorganism Center (CGMCC, No. 1, Beichen West Road, Chaoyang District, Beijing) at the General Microorganism Center of China Microbiological Culture Collection Management Committee, and its preservation number is CGMCC Acinetobacter lwoffii No. 5973.

[0027] Mix the above-mentioned biological bacteria with water to form a bacterial liquid, the density of the formed bacterial liquid is more than 60 million bacteria / ml, and set aside.

Embodiment 2

[0028] Embodiment 2 prepares fiber from flax

[0029] Using flax as raw material, specify the preparation method of the fiber.

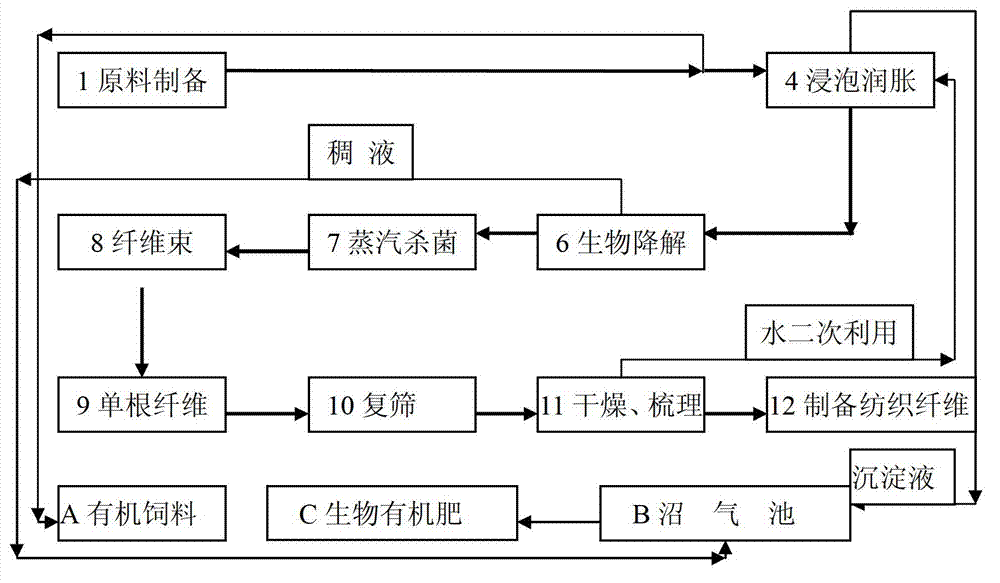

[0030] For details, please refer to figure 1 , The process flow of the fiber preparation method is divided into three stages: a preparation stage, a fiber section and a by-product section.

[0031] (1) Preparation stage: 1, 4

[0032] Immerse the harvested flax in the soaking bin or soaking tank for washing and cold soaking. First, wash away the soil and other sundries on the surface of the raw material, and soak at the same time. The water temperature is natural temperature, and the time is based on soaking and swelling. 10-12 Hour. After repeated immersion, the liquid becomes turbid, and the supernatant after flocculation and precipitation can be used again. The sediment is input into the digester for fermentation to produce biogas.

[0033] (2) Fiber section: 6-12

[0034] 6) Biodegradation: input the decomposed raw material into the biologi...

Embodiment 3

[0046] Embodiment 3 prepares cellulose from ramie

[0047] The specific preparation process is the same as in Example 2. The difference is that during biodegradation, the mass ratio of the decomposed raw material to the bacterial solution is 1:7.

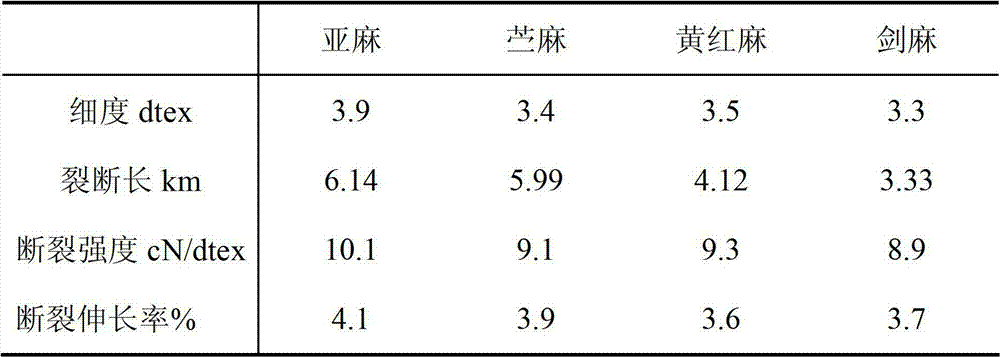

[0048] Please refer to Table 1 for the measurement results of the physical performance indexes of the obtained fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com