Method for preparing abamectin microcapsules by complex coacervation

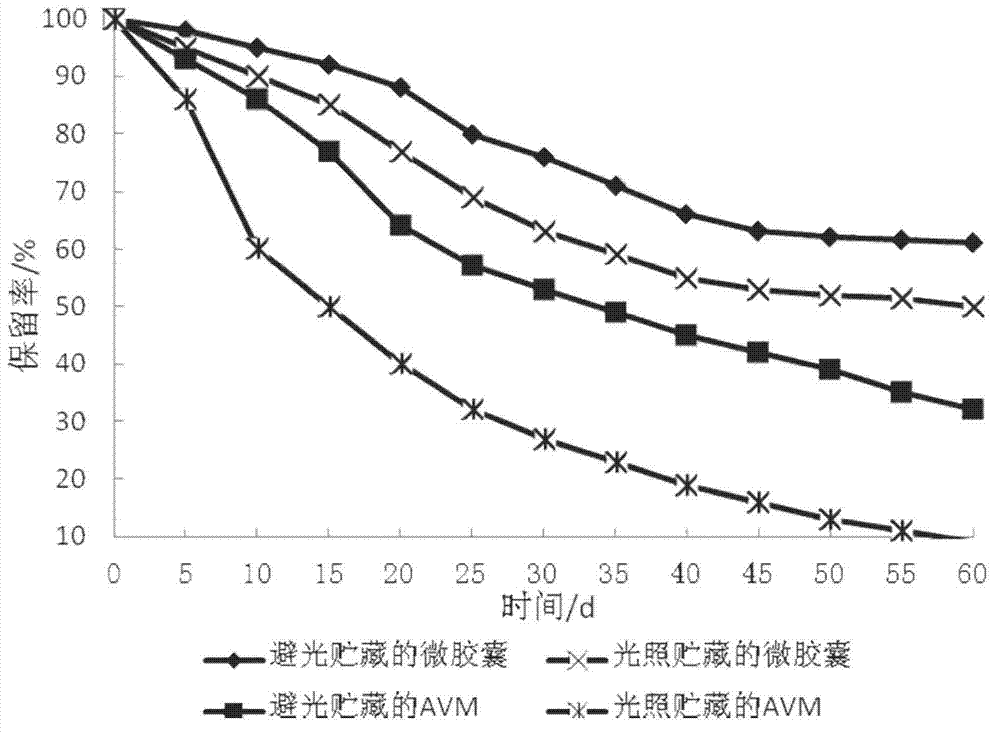

A compound coacervation method and technology of avermectin, applied in the field of microcapsule preparation, can solve the problems of high price, few studies on composite wall materials, dependence on imports of gum arabic, etc., so as to improve the duration of efficacy, reduce environmental pollution, broaden the The effect of the application path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

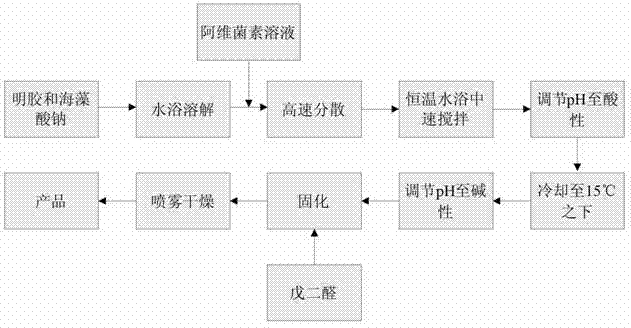

[0033] (2) Preparation of Abamectin Solution: Dissolve Abamectin in the form of powder or granules at room temperature in a solvent. The solvent is xylene to ethyl acetate with a mass ratio of 1:2~2 : 1 compound solvent, 2.0~3.0g of this solvent is needed to dissolve 1g of Abamectin;

[0034] (3) Accurately weigh the abamectin solution according to the ratio of the mass ratio of the abamectin solution to the wall material of 1:1~3:1, and add it to the wall material solution, at 10000~15000r / min High-speed dispersion and homogenization for 2-5 minutes to obtain a uniform emulsion;

[0035] (4) Add 10% acetic acid to adjust the pH to 4.4~4.8 under the condition of stirring at a temperature of 40~50°C and a rotation speed of 400~600r / min, and react for 5~10 minutes;

[0036] (5) Cool in an ice bath, at 15°C, the cooling time is 20-40 minutes, adjust the pH to 9.0-10.0, add glutaraldehyde 0.1g / g gelatin, and solidify at room temperature for 2-5 hours;

[0037] (6) Filtration and...

Embodiment 1

[0047] Preparation of Abamectin Solution: Dissolve Avermectin that is powdery or granular at normal temperature in a solvent, and the solvent is xylene and ethyl acetate with a mass ratio of 1:2 to 2:1. Compound solvent, 2.0~3.0g of the solvent is needed to dissolve 1g of Abamectin.

[0048] Weigh 4.8g of gelatin and 0.6g of sodium alginate powder, add 600g of deionized water, stir and dissolve in a 60°C water bath. Weigh 5.4g of abamectin solution, add dropwise while dispersing at high speed, the rotating speed is 15000r / min, and disperse for 2min. The mixed solution was placed at a constant temperature of 45°C and a rotational speed of 400r / min, and 10% acetic acid was added dropwise to adjust the pH to 4.6, and the composite coagulation reaction was carried out for 8 minutes. Slowly lower the temperature to below 15°C, condition the pH to 9.0, add glutaraldehyde curing agent, the dosage is 1 / 4 of the gelatin mass. Cured at room temperature for 3h.

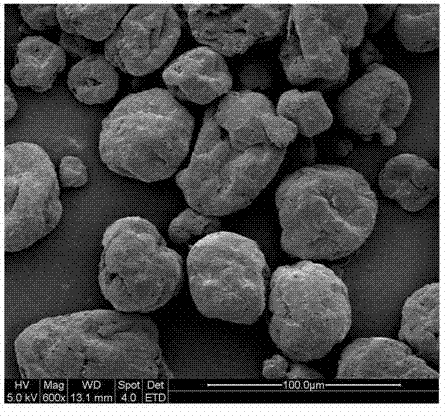

[0049] The microcapsu...

Embodiment 2

[0051]Weigh 4.8g of gelatin and 0.6g of sodium alginate powder, add 600g of deionized water, stir and dissolve in a 60°C water bath. Weigh 5.4g of abamectin solution, add dropwise while dispersing at high speed, the rotating speed is 15000r / min, and disperse for 2min. The mixed solution was placed at a constant temperature of 45°C and a rotational speed of 400r / min, and 10% acetic acid was added dropwise to adjust the pH to 4.4, and the composite coagulation reaction was carried out for 8 minutes. Slowly lower the temperature to below 15°C, condition the pH to 9.0, add glutaraldehyde curing agent, the dosage is 1 / 4 of the gelatin mass. Cured at room temperature for 3h.

[0052] Using the methanol solvent extraction method, the microencapsulation yield was 76.23% and the efficiency was 72.43% measured by ultraviolet spectrophotometry. The yield of microencapsulation decreased when the gelatin / sodium alginate deviated from the optimal pH condition. The average particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com