Method of preparing super-capacitor electrode material

A technology for supercapacitors and electrode materials, applied in the fields of new energy materials and chemical power sources, can solve the problems of unsatisfactory electrochemical characteristics such as high current discharge power characteristics and cycle life, and achieve excellent electrochemical performance, high yield, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

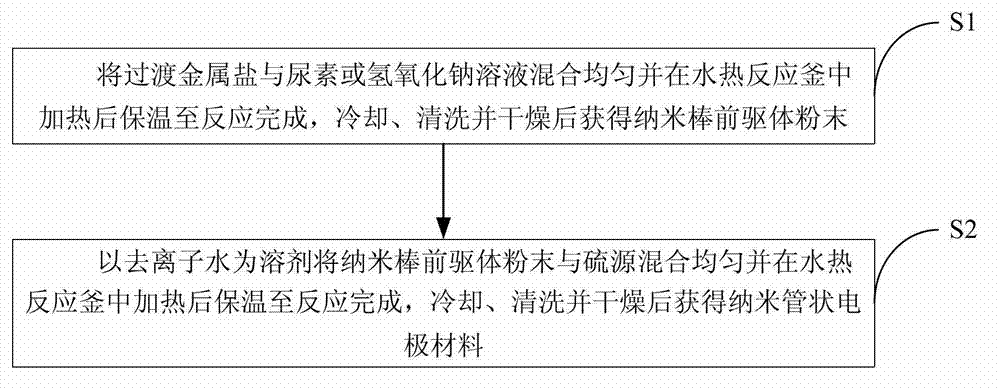

[0025] figure 1 The implementation flow of the preparation method of the supercapacitor electrode material provided by the embodiment of the present invention is shown; specifically, the following steps are included:

[0026] S1: Preparation of nanorod precursor powder

[0027] Mix the transition metal salt with urea or sodium hydroxide solution evenly, heat it in a hydrothermal reactor and keep it warm until the reaction is complete, cool, wash and dry to obtain the nanorod precursor powder;

[0028] S2: Preparation of electrode materials

[0029] Using deionized water as a solvent, mix the nanorod precursor powder and sulfur source evenly, heat in the hydrothermal reaction kettle, keep warm until the reaction is complete, cool, wash and dry to obtain nanotube electrode materials.

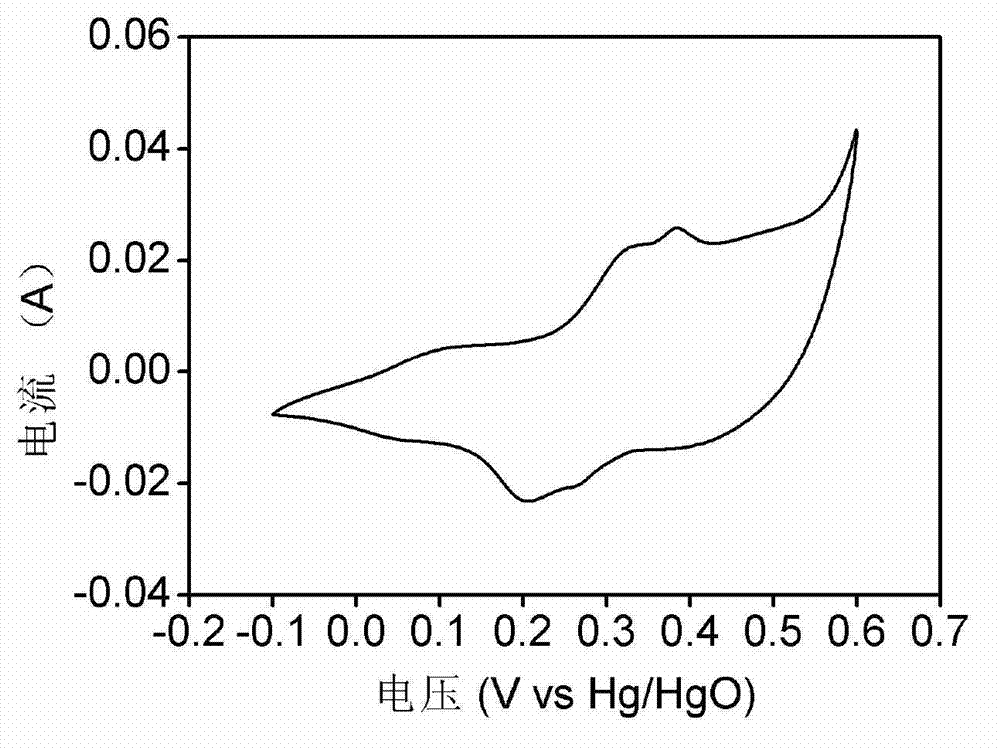

[0030] In the embodiment of the present invention, the nanorod precursor is firstly prepared by a hydrothermal method; then the precursor is mixed with a sulfur source, and the electrode materia...

Embodiment 1

[0033] (1) Preparation of precursor: Weigh 7mmol of CoCl respectively 2 ·6H 2 0 and 7 mmol of urea were placed in a reaction kettle, then filled with deionized water, magnetically stirred until uniform, and then placed in a drying oven at 80, 90, 100, 110, 120, 140, 160, and 200°C for 10 Hour. Then stop heating and cool to room temperature naturally. The sample was taken out for suction filtration, washed three times with deionized water and absolute ethanol, and dried in a blast drying oven at 60°C for 12 hours to obtain the precursor powder.

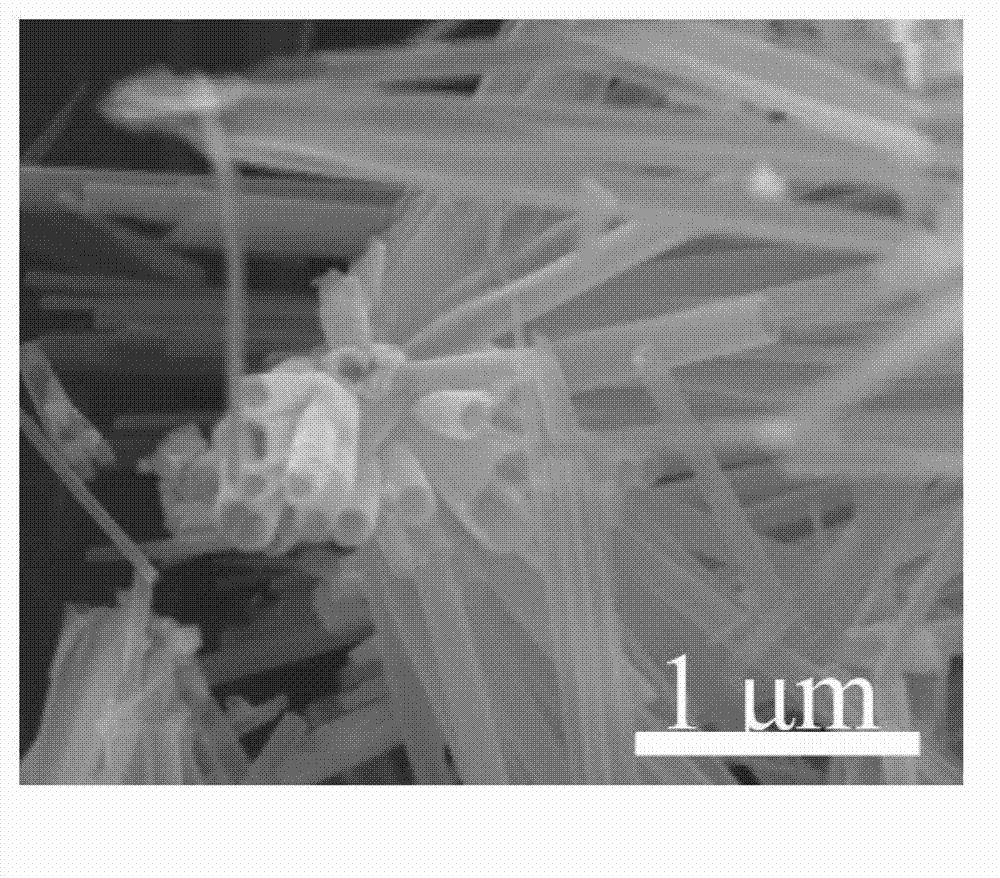

[0034] (2) Preparation of electrode materials: weigh 40 mg of precursor powder and 120 mg of Na 2 S·9H 2 O, put in a 50ml reaction kettle, then add 30ml deionized water, stir until uniform, and then keep it in a drying oven at 100, 180, and 250°C for 8 hours. Then stop heating and cool to room temperature naturally. The sample was taken out for suction filtration, washed three times with deionized water and absolute ethanol, and ...

Embodiment 2

[0042] (1) Take a certain quality of zinc chloride and sodium hydroxide to make 50ml of zinc tetrahydroxide solution as a stock solution, the ratio of zinc ion and hydroxide concentration in it is 1:20, add 5ml of stock solution to 10ml of water and 25ml of ethanol were mixed and ultrasonicated for 30min, then transferred to a 60ml lined reaction kettle, and reacted at a constant temperature of 180°C in a drying oven for 20 hours, stopped heating, cooled naturally, washed, and dried to obtain zinc oxide nanorods.

[0043] (2) Weigh the Na of zinc oxide nanorod 100mg and 600mg obtained above 2 S·9H 2 O was placed in a 50ml reaction kettle, and then 30ml of deionized water was added, magnetically stirred until uniform, and then kept in a drying oven at 180°C for 8 hours. Then stop heating and cool to room temperature naturally. The sample was taken out for suction filtration, washed three times with deionized water and absolute ethanol, and dried in a blast drying oven at 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com