Thin-film material for near field communication (NFC) equipment, and preparation method and application for thin-film material

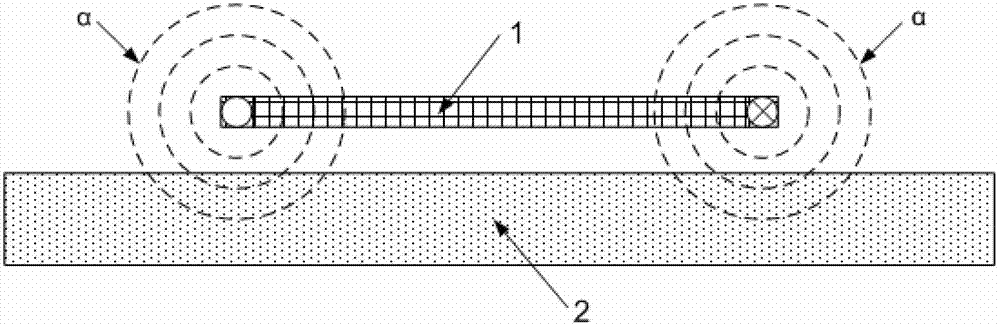

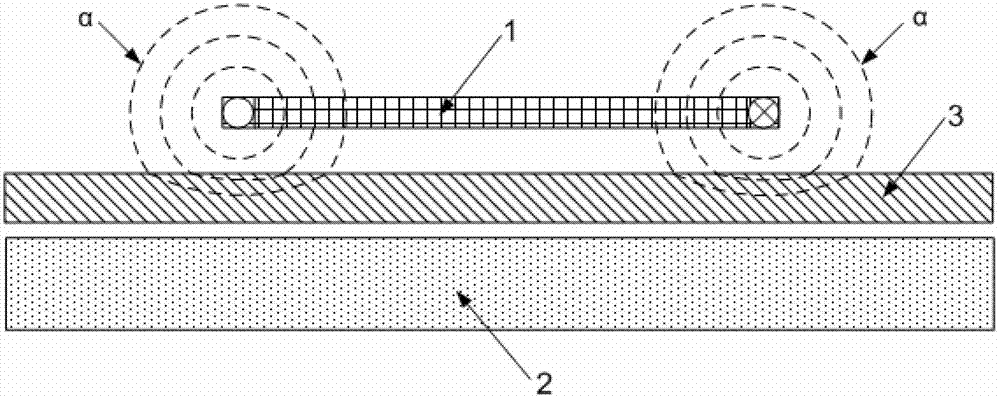

A thin-film material and equipment technology, which is applied in the field of thin-film materials for NFC equipment and its preparation, can solve problems such as eddy current loss, induced alternating electromagnetic signal eddy current loss, and entry into the interior of the metal backplane 2, so as to avoid eddy current loss and improve accuracy. Sex, the effect of good electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] (2) A preparation method of thin film material for NFC equipment

[0070] Such as Figure 4 Shown, a kind of preparation method of film material for NFC equipment, it specifically can comprise the following steps:

[0071] Step A: preparing flake-shaped iron-silicon-based alloy powder.

[0072] Wherein, the corresponding flake-shaped Fe-Si-based alloy powder can be at least one of sendust-silicon flake-shaped powder, sendust-chromium flake-shaped powder or sendust-aluminum-chromium flake-shaped powder, and these flake-shaped ferrosilicon The base alloy powder preferably satisfies the technical parameter conditions in Table 1 to Table 6 above.

[0073] Specifically, the corresponding sheet-shaped iron-silicon-based alloy powder can be prepared by the following preparation process:

[0074] Step a1, metal smelting: batching is carried out according to the component contents in Table 1, Table 3 or Table 5 above, and put into vacuum melting equipment to melt into alloy i...

Embodiment 1

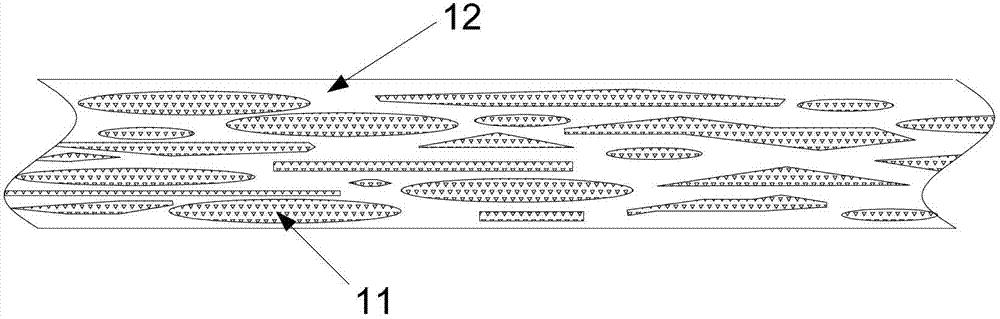

[0099] Iron, silicon and aluminum are mixed according to the ratio of Fe: Si: Al = 85: 10: 5, and after vacuum smelting, ingot making and atomization powder making, the alloy powder with a particle size of 50-150 μm is obtained; the obtained The alloy powder is processed by a flake processor for 4 to 10 hours, and then winnowed and tempered to obtain the sendust with a particle size of 50 to 150 μm, a powder thickness of ≤1.2 μm, and a powder diameter to thickness ratio of ≥450. Flake powder.

[0100] Mix the above sendust flake powder with silane coupling agent and alcohol according to the ratio of sendust flake powder: silane coupling agent: alcohol = 100:1:100, fully stir and dry to obtain coating Good sendust flake powder;

[0101] Mix the above-coated sendust flake powder and polyurethane adhesive according to the ratio of coated sendust flake powder: polyurethane adhesive = 85:15, and extrusion-coat on the PET plastic film. Cloth; apply a 400-500Gs unidirectional magne...

Embodiment 2

[0104] Iron, silicon and chromium are mixed according to the ratio of Fe: Si: Cr = 88: 10: 2, after vacuum melting ingot making and atomization powder making, the alloy powder with a particle size of 50-100 μm is obtained; the prepared The alloy powder is processed by a flake processor for 4 to 10 hours, and then winnowed and tempered to obtain iron silicon chromium with a particle size of 50 to 150 μm, a powder thickness of ≤1.2 μm, and a powder diameter to thickness ratio of ≥450. Flake powder.

[0105] Mix the above iron silicon chromium sheet powder with silane coupling agent and alcohol according to the ratio of iron silicon chromium sheet powder: silane coupling agent: alcohol = 100:1:100, fully stir and dry to obtain coating Good FeSiCr flake powder;

[0106] Put the above-coated ferrosilicon chromium flake powder with polyurethane adhesive and epoxy resin adhesive, according to the ratio of coated ferrosilicon chromium flake powder: polyurethane adhesive: epoxy resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com