Rear cross-linking heatproof emulsion pressure-sensitive adhesive and method for producing same

A cross-linking, heat-resistant technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problem of difficulty in obtaining, expensive polymer emulsifiers and reactive emulsifiers, and inapplicability Large-scale production and other issues, to achieve the effect of easy control, good high temperature resistance, and stable storage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

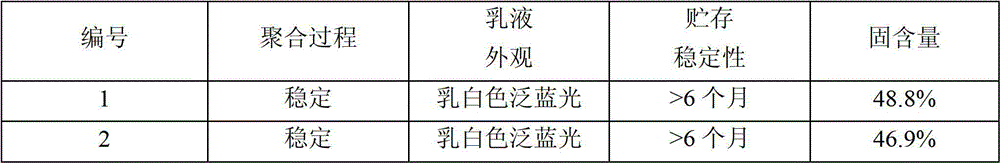

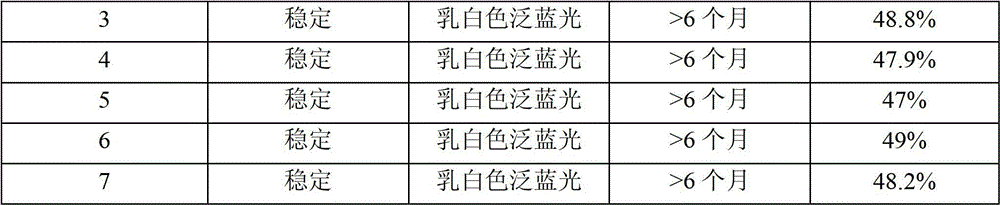

Examples

Embodiment 1

[0049] (1) Pre-emulsion preparation

[0050] 130g butyl acrylate, 70g methyl methacrylate, 0.05g sodium carbonate, 0.33g sodium dodecylsulfonate, 0.67g nonylphenol polyoxyethylene (9) ether, 0.02g diacetone acrylamide, 150g Ionized water and 0.18 g of potassium persulfate were mixed, and after mechanical stirring and mixing, a milky white milk-like pre-emulsion was obtained.

[0051] (2) Emulsion polymerization

[0052] Put the four-necked reaction round-bottom bottle equipped with a mechanical stirrer, reflux condenser, thermometer and constant pressure funnel into the reactor after adding 50g of deionized water and heating it to 80°C in a water bath, stirring at a speed of 150r / min. Add 0.02g of potassium persulfate and 10g of the pre-emulsion prepared in step (1). After the blue color appears in the system, start to add the pre-emulsion obtained in the remaining step (1) dropwise through the constant pressure funnel, and the dropwise addition is completed within 2 to 3 ho...

Embodiment 2

[0058] (1) Pre-emulsion preparation

[0059] 200g isooctyl acrylate, 8g acrylic acid, 2g sodium carbonate, 2g sodium dodecylsulfonate, 4g sorbitol polyoxyethylene (20) ether (POE), 4g diacetone acrylamide, 150g deionized water and 3.6g Potassium persulfate was mixed, and after mechanical stirring and mixing, a milky white milk-like pre-emulsion was obtained.

[0060] (2) Emulsion polymerization

[0061] Add 50g of deionized water into a four-necked reaction round-bottom bottle equipped with a mechanical stirrer, reflux condenser, thermometer and constant pressure funnel, place it in a water bath, heat it to 80°C, stir at 250r / min, and add to the reactor 0.4g potassium persulfate and the pre-emulsion prepared in step (1) of 60g. After the blue phase appears in the system, start to add the remaining pre-emulsion obtained in step (1) dropwise through the constant pressure funnel, and complete the dropwise addition within 2 to 3 hours, keep the temperature for 2 hours to complet...

Embodiment 3

[0067] (1) Pre-emulsion preparation

[0068] Take 160g butyl acrylate, 40g methyl methacrylate, 6g acrylic acid, 0.05g sodium carbonate, 1.6g sodium lauryl sulfate, 3.2g octylphenol polyoxyethylene (9) ether, 0.04g diacetone acrylamide, 50g of deionized water and 0.9g of potassium persulfate were mixed and mechanically stirred to obtain a milky white milk-like pre-emulsion.

[0069] (2) Emulsion polymerization

[0070] Add 50g of deionized water into a four-necked reaction round-bottom bottle equipped with a mechanical stirrer, reflux condenser, thermometer and constant pressure funnel, place it in a water bath, heat it to 80°C, stir at 250r / min, and add to the reactor 0.1g of potassium persulfate and 60g of the pre-emulsion prepared in step (1). After the blue phase appears in the system, start to add the pre-emulsion obtained in the remaining step (1) dropwise through the constant pressure funnel. The dropwise addition is completed within 2 to 3 hours, and the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com