Method for preparing double-meso-pore ordered mesoporous carbon/ polyaniline nanometer line composite materials and application thereof

A composite material and mesoporous carbon technology, applied in capacitors, circuits, electrolytic capacitors, etc., can solve the problems of reducing the high-speed charge and discharge capacity of supercapacitors, hindering the migration and diffusion of electrolyte ions, and achieving good cycle stability. Transport and diffusion, effect of increasing pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

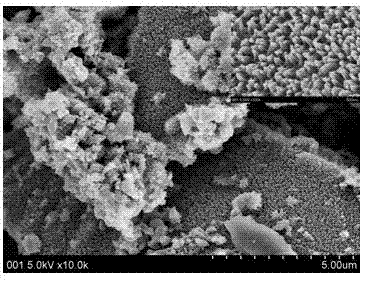

[0030] Weigh 0.32g of ammonium persulfate into 10ml of deionized water, and cool in a refrigerator. 0.15 g of ordered mesoporous carbon with carbon walls embedded with silica particles was ultrasonically dispersed in 10 ml of 1M sulfuric acid solution. Add 0.14g of aniline monomer to the above mixing system, stir under vacuum for 60 minutes, then quickly add 10ml of 20wt% ethanol solution, add dropwise the pre-cooled ammonium persulfate solution, stir and react under ice bath for 10 hours, filter, A black powder was obtained after washing. After drying, the silica particles were removed with 10wt% hydrofluoric acid solution to obtain a double mesoporous composite material containing 60% polyaniline. Electron microscope photographs of the product figure 1 shown.

Embodiment 2

[0032] Weigh 0.64g of ammonium persulfate into 10ml of deionized water, and cool in a refrigerator. 0.15 g of ordered mesoporous carbon with carbon walls embedded with silica particles was ultrasonically dispersed in 10 ml of 1M sulfuric acid solution. Add 0.28g of aniline monomer to the above mixing system, stir under vacuum for 60 minutes, then quickly add 10ml of 20wt% ethanol solution, add dropwise the pre-cooled ammonium persulfate solution, stir and react under ice bath for 10 hours, filter, A black powder was obtained after washing. After drying, the silica particles were removed with 10wt% hydrofluoric acid solution to obtain a double mesoporous composite material containing 86% polyaniline.

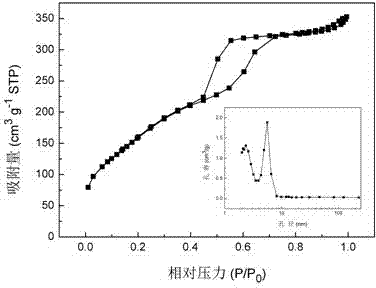

[0033] Nitrogen adsorption-desorption analyzer (Micromeritics ASAP 2020) was used to characterize the specific surface area and pore size distribution of the dual mesoporous composite material prepared in the above example 1, the results are as follows figure 2 and shown in Ta...

Embodiment 3

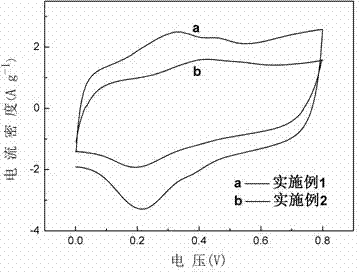

[0034] Example 3 Characterization of the electrochemical test of the double mesoporous composite material

[0035] Mix the composite material prepared in Examples 1 and 2, conductive carbon black and polytetrafluoroethylene emulsion in a mass ratio of 85:10:5, add a small amount of absolute ethanol, and press it into a thin sheet with a thickness of about 1mm. Punched into a disc with a diameter of 11mm, and then compacted under a pressure of 10MPa. A simulated supercapacitor was assembled by using two electrodes with equal mass as the positive and negative electrodes of the capacitor, sandwiching a diaphragm, and using 1 M sulfuric acid solution as the electrolyte. The assembled supercapacitor was subjected to cyclic voltammetry and constant current charge and discharge tests at the electrochemical workstation, and the results were as follows: Figure 4 . According to the formula The specific capacitance values corresponding to the dual mesoporous composites at differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com